Graphite stands out as the ideal material for electrodes due to its remarkable properties. Its ability to conduct electricity efficiently ensures reliable performance in demanding applications. You can rely on its thermal stability, even in extreme heat. Graphite’s chemical resistance makes it durable in harsh environments. Whether used as a graphite electrode, graphite ring, or graphite block, it delivers unmatched versatility and cost-effectiveness.

Key Takeaways

- Graphite electrodes carry electricity well because of their special structure. This lets electrons move easily and ensures they work reliably in many uses.

- Graphite can handle very high heat, over 3,000°C, without breaking. This makes it perfect for hot industrial jobs like making steel or electrolysis.

- Graphite resists chemicals, so it lasts long in tough places. It keeps working without wearing out, saving time and money on new parts.

Electrical Conductivity of Graphite Electrodes

How Graphite’s Atomic Structure Enables Conductivity

Graphite’s atomic structure plays a key role in its ability to conduct electricity. You might already know that graphite is made of carbon atoms arranged in layers. Each carbon atom bonds with three others, forming a hexagonal pattern. This unique arrangement creates a strong yet flexible structure.

One of the most fascinating aspects of graphite is its layered design. These layers are held together by weak forces, allowing them to slide over each other. This property not only makes graphite soft but also contributes to its excellent conductivity. The structure allows electrons to move freely across the layers, making it an ideal material for electrodes.

The Role of Delocalized Electrons in Current Flow

The movement of delocalized electrons is what makes graphite electrodes so effective. In graphite, one electron from each carbon atom is not tied to a specific bond. These free electrons, also known as delocalized electrons, can move throughout the material.

When you apply an electric current, these electrons flow effortlessly, carrying the charge. This is why graphite electrodes perform so well in applications like arc furnaces or electrolysis. Their ability to handle high currents without significant resistance ensures reliable performance.

You can think of delocalized electrons as a highway for electricity. They allow the current to travel smoothly, making graphite electrodes a top choice for industries worldwide.

Thermal Stability of Graphite Electrodes

Resistance to High Temperatures

Graphite electrodes excel in high-temperature environments. You might wonder why this is important. Many industrial processes, such as steelmaking or smelting, involve extreme heat. Graphite can withstand temperatures exceeding 3,000°C without melting or breaking down. This makes it one of the most heat-resistant materials available.

The secret lies in graphite’s structure. Its carbon atoms form strong covalent bonds within layers, giving it incredible thermal stability. Even when exposed to intense heat, graphite maintains its integrity. Unlike other materials, it does not deform or lose its properties.

You can rely on graphite electrodes to perform consistently, even in the harshest conditions. This resistance to high temperatures ensures that they remain effective and reliable over long periods.

Importance of Thermal Stability in Industrial Applications

Thermal stability plays a critical role in industrial applications. Processes like electric arc furnaces or electrolysis generate extreme heat. If the electrode material cannot handle these temperatures, it will fail. This can lead to costly downtime and reduced efficiency.

Graphite electrodes solve this problem. Their ability to endure high temperatures ensures uninterrupted operation. You can trust them to deliver consistent performance, even in demanding environments.

Thermal stability also reduces wear and tear. This means you won’t need to replace graphite electrodes as often, saving time and money. Their durability makes them a cost-effective choice for industries worldwide.

When you choose graphite electrodes, you invest in reliability and efficiency. Their thermal stability ensures they meet the demands of modern industrial processes.

Chemical Resistance and Durability of Graphite Electrodes

Graphite’s Inertness in Harsh Environments

Graphite electrodes perform exceptionally well in chemically aggressive environments. You might wonder why this is important. Many industrial and electrochemical processes involve exposure to corrosive substances like acids, alkalis, or salts. Materials that lack chemical resistance degrade quickly in such conditions. Graphite, however, remains stable and inert.

This inertness comes from its unique carbon structure. The strong covalent bonds within its layers make it resistant to chemical reactions. Even when exposed to harsh chemicals, graphite does not corrode or break down. This property ensures that graphite electrodes maintain their performance over time.

You can rely on graphite electrodes to handle challenging environments without compromising efficiency. Their chemical resistance makes them a dependable choice for industries like metal refining, battery production, and wastewater treatment.

Longevity in Electrochemical Processes

Durability is another key advantage of graphite electrodes. In electrochemical processes, electrodes often face wear and tear due to constant current flow and chemical exposure. Materials that lack durability require frequent replacement, increasing costs and downtime.

Graphite electrodes, on the other hand, offer long-lasting performance. Their resistance to chemical attack and thermal stress ensures minimal degradation over time. This durability allows you to use them for extended periods without sacrificing efficiency.

For example, in processes like electrolysis, graphite electrodes maintain their structural integrity even after prolonged use. This longevity reduces maintenance needs and enhances overall productivity. By choosing graphite electrodes, you invest in a solution that delivers consistent results and long-term value.

Cost-Effectiveness and Versatility of Graphite Electrodes

Affordability Compared to Alternative Materials

Graphite electrodes offer a cost-effective solution for industrial and electrochemical applications. Compared to alternative materials like copper or tungsten, graphite provides similar or superior performance at a fraction of the cost. This affordability makes it an attractive choice for industries that require reliable and efficient electrodes.

You might wonder why graphite is so economical. The answer lies in its abundance and ease of extraction. Graphite is widely available in nature, which keeps its raw material costs low. Additionally, the manufacturing process for graphite electrodes is less energy-intensive than that of other materials, further reducing expenses.

By choosing graphite electrodes, you can achieve high performance without exceeding your budget. This balance of quality and affordability ensures that graphite remains a top choice for businesses worldwide.

Ease of Shaping and Manufacturing

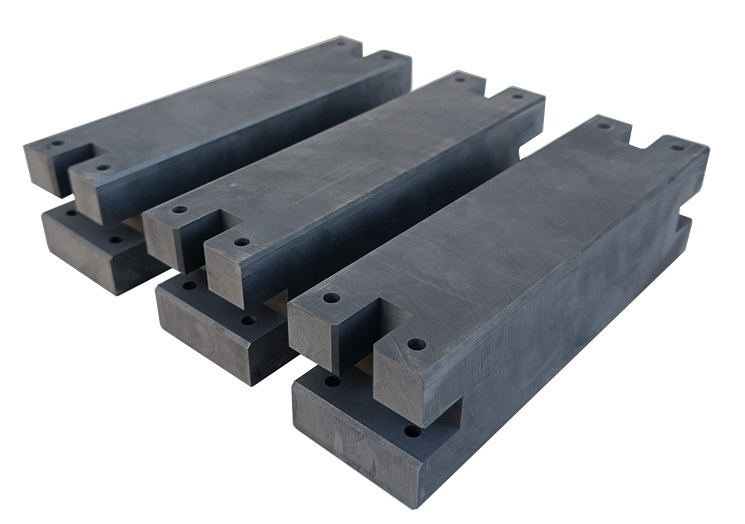

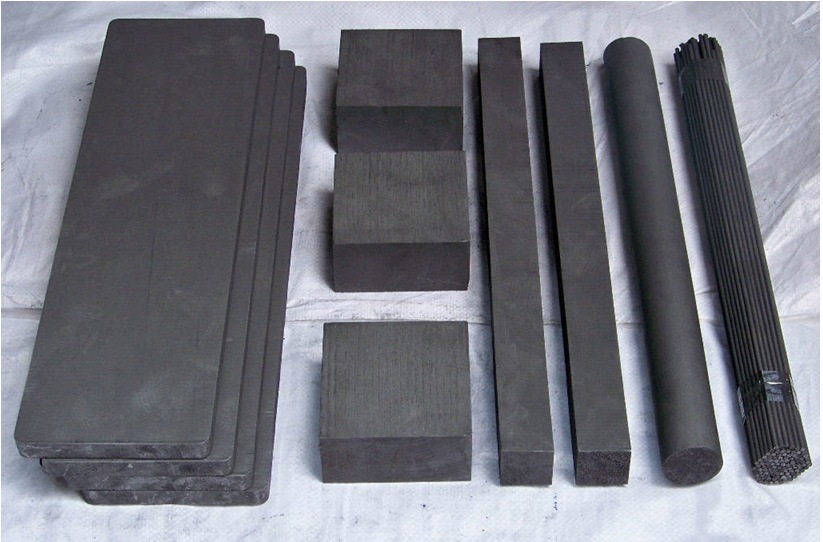

Graphite electrodes are incredibly versatile due to their ease of shaping and manufacturing. Unlike harder materials, graphite is soft and machinable. This property allows manufacturers to create electrodes in various shapes and sizes to meet specific industrial needs.

You can customize graphite electrodes for applications ranging from arc furnaces to battery production. The material’s flexibility ensures that it can adapt to different designs without compromising performance. For example, manufacturers can easily drill, cut, or mold graphite into complex geometries, making it suitable for specialized processes.

The straightforward manufacturing process also reduces production time and costs. This efficiency benefits industries by providing high-quality electrodes quickly and affordably. When you choose graphite electrodes, you gain access to a material that combines adaptability with practicality.

Graphite electrodes combine electrical conductivity, thermal stability, chemical resistance, and affordability. These qualities make them the best choice for industrial and electrochemical applications. You can rely on their performance in demanding environments. Whether you need durability or cost-effectiveness, a graphite electrode delivers unmatched efficiency and value across a wide range of uses.

FAQ

What makes graphite electrodes better than copper electrodes?

Graphite electrodes offer superior thermal stability, chemical resistance, and affordability. You can also shape them easily, making them more versatile for industrial applications.

Can graphite electrodes handle extreme temperatures?

Yes! Graphite electrodes withstand temperatures over 3,000°C. Their strong carbon bonds ensure durability and performance in high-heat environments like steelmaking or smelting.

Are graphite electrodes environmentally friendly?

Graphite electrodes are eco-friendly. Their manufacturing process consumes less energy compared to alternatives. You also benefit from their long lifespan, reducing waste and replacement frequency.

For more product details, please contact steven@china-vet.com Or website: www.vet-china.com.