Graphite Rotors & Vanes are essential for boosting energy-efficient cooling in electric vehicle motors. The graphite rotor, with its high thermal conductivity, ensures efficient heat dissipation, while its lightweight design reduces energy consumption. Additionally, components such as the graphite impeller and graphite degassing rotor enhance motor performance by minimizing energy loss, promoting long-term durability and sustainability.

Key Takeaways

- Graphite Rotors & Vanes help cool EV motors better. They stop motors from overheating and keep them working well.

- These lightweight graphite parts use less energy, helping EVs drive farther.

- Graphite moves heat away quickly, saving energy and making motors last longer.

Importance of Cooling in EV Motors

Why Cooling Matters for EV Performance

Efficient cooling plays a pivotal role in ensuring the optimal performance of electric vehicle (EV) motors. Motors generate significant heat during operation, especially under high loads or extended use. Without proper cooling, this heat can accumulate, leading to reduced efficiency and potential damage to motor components. Advanced cooling systems, such as those incorporating Graphite Rotors & Vanes, help maintain the motor’s temperature within an ideal range, ensuring consistent performance and reliability.

The effectiveness of cooling methods can be observed in their ability to reduce motor temperatures. For instance, water-cooling systems have demonstrated a temperature reduction of over 50% in certain cases, as shown in the table below:

| Cooling Method | Temperature Range (°C) | Temperature Reduction (%) | Notes |

|---|---|---|---|

| Water-Cooling | 17–124 | 50.4% (Aluminum casing) | Significant reduction in temperature compared to air-cooling. |

| Water-Cooling | 17–124 | 48.4% (PA6GF30 casing) | Demonstrates effectiveness of water-cooling in thermal management. |

| PCM Cooling | N/A | N/A | PCM lowers hot spot temperature through latent heat energy storage. |

Effects of Overheating on Motor Efficiency

Overheating negatively impacts the efficiency of EV motors. When the motor exceeds its optimal temperature range of 90–95 °C, it may enter a safe mode to prevent damage, reducing its output. Additionally, overheating accelerates wear and tear on components, shortening the motor’s lifespan.

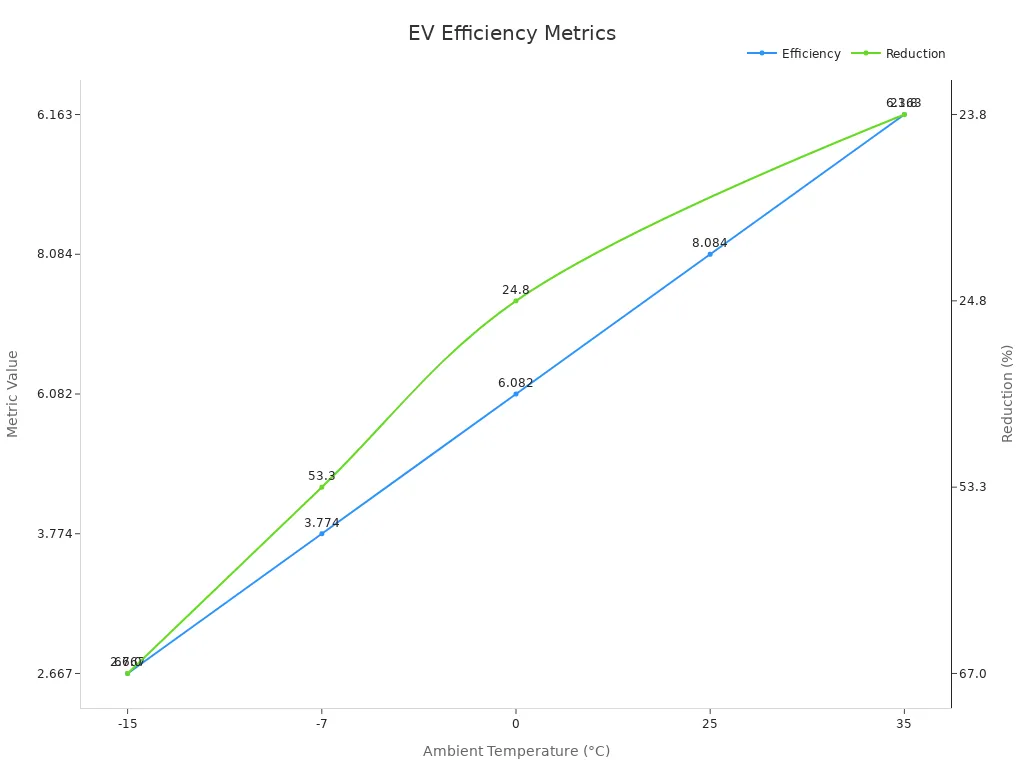

Quantitative data highlights the consequences of operating at extreme temperatures. For example, at -15 °C, energy consumption efficiency drops by 67%, as shown in the chart below:

Maintaining the motor within its optimal temperature range not only prevents these issues but also ensures consistent energy efficiency and performance.

Role of Cooling in Energy Savings

Effective cooling systems contribute significantly to energy savings in EVs. By maintaining the motor and battery within their ideal temperature ranges, these systems reduce energy loss caused by overheating or excessive cooling demands. For instance, phase change materials (PCMs) can store up to 500 Joules of heat energy, effectively managing thermal loads and reducing the need for additional energy-intensive cooling measures.

Moreover, advanced cooling technologies, such as those utilizing Graphite Rotors & Vanes, enhance thermal management while minimizing energy consumption. Their lightweight design reduces the overall weight of the cooling system, further improving the vehicle’s energy efficiency.

Graphite Rotors & Vanes in EV Cooling

What Are Graphite Rotors & Vanes?

Graphite rotors and vanes are critical components in advanced cooling systems for electric vehicle (EV) motors. These parts are typically crafted from high-quality graphite, a material known for its exceptional thermal and mechanical properties. Rotors are rotating elements that facilitate the movement of cooling fluids, while vanes are stationary or movable blades that direct the flow of these fluids. Together, they form an integral part of the cooling mechanism, ensuring efficient heat dissipation and maintaining optimal motor temperatures.

In EV applications, graphite rotors and vanes stand out due to their ability to operate under high thermal loads without compromising performance. Their lightweight nature reduces the overall weight of the cooling system, contributing to improved energy efficiency. These components are designed to withstand the demanding conditions of EV motors, including high rotational speeds and prolonged operational cycles, making them indispensable for modern thermal management systems.

Key Properties of Graphite for Cooling

Graphite possesses unique properties that make it ideal for cooling applications in EV motors. Its high thermal conductivity ensures rapid heat transfer, preventing the accumulation of excess heat within the motor. This property is particularly beneficial in high-performance EVs, where efficient cooling is essential to maintain consistent motor output.

Another key attribute of graphite is its lightweight nature. Compared to traditional materials like metals, graphite significantly reduces the weight of cooling components, enhancing the overall energy efficiency of the vehicle. Additionally, graphite exhibits excellent chemical resistance, ensuring durability and reliability even in harsh operating environments.

The material’s versatility extends to its ability to integrate with other cooling technologies. For instance, studies have shown that combining graphite with phase change materials (PCMs) can enhance thermal management. In one experiment, battery cells equipped with PCMs and aluminum wire mesh plates achieved a surface temperature reduction from 62.5°C to 46.5°C, representing a 25% improvement in thermal management. This demonstrates the effectiveness of graphite in optimizing cooling performance.

How They Improve Thermal Management

Graphite rotors and vanes play a pivotal role in improving the thermal management of EV motors. By facilitating efficient heat dissipation, these components help maintain the motor’s temperature within its optimal range, preventing overheating and ensuring consistent performance. Their high thermal conductivity allows for rapid heat transfer, reducing the risk of thermal hotspots that could compromise motor efficiency.

The lightweight design of graphite components further enhances their contribution to thermal management. By reducing the overall weight of the cooling system, they minimize the energy required for cooling operations, leading to improved energy efficiency. This is particularly important in EVs, where every unit of energy saved contributes to extended driving range and reduced environmental impact.

Moreover, the durability of graphite ensures long-term performance, even under demanding conditions. These components can withstand high rotational speeds and thermal loads without degrading, making them a reliable choice for advanced cooling systems. Their integration into EV motors not only enhances thermal management but also supports the broader goals of sustainability and energy efficiency in electric mobility.

Advantages of Graphite in Energy Efficiency

Superior Thermal Conductivity

Graphite’s superior thermal conductivity makes it an exceptional material for cooling systems in electric vehicle (EV) motors. Its ability to transfer heat efficiently ensures that motor components remain within their optimal temperature range, preventing overheating and maintaining consistent performance. Laboratory tests highlight the remarkable thermal conductivity of graphite compared to other materials.

| Material Type | Thermal Conductivity (W·m-1 K-1) |

|---|---|

| Graphite Phase | 5.6 |

| Air | 0.026 |

This data underscores graphite’s ability to dissipate heat far more effectively than air, making it an indispensable component in advanced cooling systems. By incorporating graphite into EV motors, manufacturers can achieve better thermal management, which directly contributes to energy efficiency and prolonged motor lifespan.

Lightweight Design for Reduced Energy Use

The lightweight nature of graphite significantly reduces the overall weight of cooling systems in EVs. This reduction translates into lower energy consumption, as the motor requires less power to operate efficiently. Studies conducted by the U.S. Department of Energy’s Pacific Northwest National Laboratory emphasize the importance of lightweight materials in improving motor efficiency.

Researchers at the U.S. Department of Energy’s Pacific Northwest National Laboratory found that adding graphene to copper wiring can improve the performance of electric motors. An 11% increase in electrical conductivity of copper wire winding translates into a 1% gain in motor efficiency, which means less energy is drained from the vehicle’s battery.

This finding demonstrates how lightweight materials like graphite can enhance the overall energy efficiency of EV motors. By reducing the energy demands of cooling systems, graphite contributes to extended driving ranges and supports the development of sustainable electric mobility solutions.

Durability for Long-Term Performance

Graphite’s durability ensures reliable performance over extended periods, even under demanding operating conditions. Unlike other materials that degrade quickly, graphite maintains its structural integrity and thermal properties over time. Long-term performance data highlights its resilience in cooling applications.

| Material | Initial Thermal Resistance | After 120 Cycles | Deterioration Level |

|---|---|---|---|

| Grease | Significantly deteriorated | Deteriorated | High |

| GraphiteTIM | Slightly deteriorated | Maintained | Low |

Additionally, graphite components exhibit:

- High reliability over time.

- An operating temperature range of -55 to 400 ℃.

These attributes make graphite an ideal choice for EV cooling systems, where consistent performance and durability are critical. By integrating graphite rotors and vanes into their designs, manufacturers can ensure long-term efficiency and reduced maintenance costs, further enhancing the sustainability of electric vehicles.

Graphite vs. Alternative Materials

Comparison with Metals

Metals, such as aluminum and copper, are commonly used in cooling systems due to their high thermal conductivity. However, they come with significant drawbacks. Metals are dense, which increases the overall weight of the cooling system. This added weight reduces the energy efficiency of electric vehicles (EVs). Additionally, metals are prone to corrosion over time, especially in environments with high humidity or exposure to cooling fluids.

Graphite, on the other hand, offers a lightweight alternative with comparable thermal conductivity. Unlike metals, graphite resists corrosion, ensuring long-term reliability. Its lower density also reduces the strain on EV motors, contributing to improved energy efficiency.

| Property | Metals (e.g., Aluminum) | Graphite |

|---|---|---|

| Thermal Conductivity | High | High |

| Weight | Heavy | Lightweight |

| Corrosion Resistance | Low | High |

Comparison with Ceramics

Ceramics are another material used in cooling applications due to their thermal stability and resistance to high temperatures. However, ceramics are brittle and prone to cracking under mechanical stress. This limits their durability in dynamic environments like EV motors, where components experience constant movement and vibration.

Graphite surpasses ceramics in mechanical resilience. Its flexibility and structural integrity allow it to withstand high rotational speeds and thermal loads without fracturing. Furthermore, graphite’s thermal conductivity is superior to most ceramics, making it more effective for heat dissipation.

Why Graphite Is the Best Choice

Graphite combines the best properties of metals and ceramics while eliminating their limitations. It delivers high thermal conductivity, lightweight design, and exceptional durability. These qualities make it the ideal material for EV cooling systems. Its ability to resist corrosion and mechanical stress ensures long-term performance, reducing maintenance costs and enhancing energy efficiency.

Graphite’s unique combination of properties positions it as the optimal choice for advanced cooling systems, driving innovation in sustainable electric mobility.

Real-World Applications of Graphite Rotors & Vanes

Examples in EVs and Other Industries

Graphite Rotors & Vanes have found widespread applications across various industries, including electric vehicles (EVs), aerospace, and energy storage. In EVs, these components enhance cooling efficiency, ensuring optimal motor performance and extended battery life. Companies like AllCell Technology utilize graphite composite materials for phase-change cooling in lithium-ion batteries, significantly improving cell longevity. Similarly, Advanced Cooling Technologies integrates phase-change material (PCM) heat sinks into EVs, spacecraft, and missile systems, showcasing the versatility of graphite-based solutions. Heat Pipe Cooling combines heat pipes with PCM to stabilize battery temperatures, further enhancing performance and durability.

| Company Name | Technology Description |

|---|---|

| AllCell Technology | Utilizes a graphite composite material for phase-change cooling in lithium-ion batteries, enhancing cell life. |

| Advanced Cooling Technologies | Offers PCM heat sinks for EVs, applicable in various industries including spacecraft and missiles. |

| Heat Pipe Cooling | Combines heat pipes with PCM to stabilize battery temperatures, improving performance and lifespan. |

These examples highlight the adaptability of graphite-based cooling components in addressing diverse thermal management challenges.

Proven Energy Efficiency Improvements

Graphite-based cooling systems have demonstrated measurable energy efficiency improvements in real-world applications. By leveraging graphite’s superior thermal conductivity, these systems reduce energy loss caused by overheating. For instance, phase-change cooling technologies incorporating graphite have been shown to extend battery life by maintaining stable temperatures. In EV motors, the lightweight design of graphite components minimizes energy consumption, directly contributing to longer driving ranges. These advancements underline the critical role of graphite in optimizing energy use across industries.

Future Trends in Graphite-Based Cooling

The future of graphite-based cooling lies in its integration with emerging technologies. Researchers are exploring hybrid systems that combine graphite with advanced materials like graphene and nanocomposites to further enhance thermal performance. Additionally, the growing adoption of solid-state batteries in EVs presents new opportunities for graphite-based cooling solutions. As industries prioritize sustainability, the demand for lightweight, durable, and energy-efficient materials like graphite will continue to rise. These trends position graphite as a cornerstone of next-generation cooling technologies.

Graphite Rotors & Vanes play a vital role in advancing energy-efficient cooling for EV motors. Their unmatched thermal conductivity, lightweight structure, and durability enhance motor performance while reducing energy loss. Ningbo VET Energy Technology Co. leads the industry by producing high-quality graphite components, driving innovation in sustainable electric vehicle technology.

FAQ

What makes graphite rotors and vanes ideal for EV cooling systems?

Graphite’s high thermal conductivity, lightweight design, and durability optimize heat dissipation, reduce energy consumption, and ensure long-term reliability in electric vehicle motors.

How do graphite components improve energy efficiency in EVs?

Graphite reduces cooling system weight, minimizes energy loss, and enhances thermal management, directly contributing to extended driving ranges and sustainable electric mobility.

Are graphite rotors and vanes compatible with other cooling technologies?

Yes, graphite integrates seamlessly with phase-change materials and hybrid systems, enhancing thermal performance and supporting advanced cooling solutions in EVs and other industries.