In the world of semiconductor production, the Contiguous Wafer Boat stands as a game-changer. You will find it directly enhances your manufacturing processes. This innovative tool boosts efficiency by streamlining wafer handling. It reduces costs by minimizing damage and waste. Technological advancements in its design ensure precision and reliability. By integrating the Contiguous Wafer Boat into your operations, you optimize performance and elevate your production capabilities. Experience the benefits firsthand and see how this essential tool transforms your semiconductor manufacturing.

Key Takeaways

- The Contiguous Wafer Boat significantly enhances semiconductor manufacturing by improving wafer handling precision, which reduces the risk of damage and waste.

- Integrating this innovative tool into your production line can lead to increased throughput and higher yield rates, ultimately boosting your bottom line.

- By lowering operational costs through minimized wafer damage, the Contiguous Wafer Boat allows for more efficient resource allocation in your manufacturing processes.

- The versatility of the Contiguous Wafer Boat accommodates various wafer sizes, making it easier to adapt to different production needs without extensive adjustments.

- Embracing the Contiguous Wafer Boat positions your operations to leverage modern manufacturing technologies, enhancing overall efficiency and reducing human error.

- Real-world success stories demonstrate that adopting the Contiguous Wafer Boat can lead to significant improvements in yield rates and reductions in downtime.

- Staying informed about future developments in wafer boat design can help you remain competitive and responsive to the evolving semiconductor market.

Challenges in Semiconductor Production

Complexity of Manufacturing Processes

In semiconductor production, you face intricate manufacturing processes. Each step requires precision and accuracy. You must handle delicate materials and advanced technologies. The complexity increases as you integrate more components into smaller spaces. This demands a high level of expertise and meticulous attention to detail. You need to ensure that every process aligns perfectly to maintain the integrity of the final product.

Yield and Quality Control Issues

Achieving high yield and maintaining quality control present significant challenges. You strive to produce as many functional chips as possible from each wafer. However, defects can occur at any stage, affecting yield rates. You must implement rigorous quality control measures to detect and rectify these issues. Consistency in quality is crucial for meeting industry standards and customer expectations. You need to continuously monitor and improve your processes to enhance yield and quality.

Cost Constraints and Economic Pressures

Economic pressures and cost constraints are ever-present in semiconductor manufacturing. You must balance the need for cutting-edge technology with budget limitations. The cost of raw materials, equipment, and labor can be substantial. You aim to optimize production efficiency to reduce expenses. Market competition also drives you to innovate while keeping costs manageable. Finding ways to lower operational costs without compromising quality is essential for staying competitive in the industry.

Contiguous Wafer Boat: A Revolutionary Solution

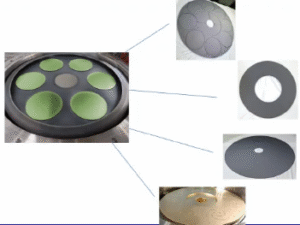

Definition and Basic Functionality

The Contiguous Wafer Boat is a cutting-edge tool designed to enhance semiconductor manufacturing. You use it to securely hold and align wafers during processing. This ensures precision and reduces the risk of damage. The boat’s design accommodates various wafer sizes, making it versatile for different production needs. Its high-quality materials provide thermal stability and chemical resistance. This makes it suitable for high-temperature and harsh chemical environments. By integrating the Contiguous Wafer Boat into your production line, you improve throughput and yield rates.

Historical Development and Evolution

The development of the Contiguous Wafer Boat has transformed semiconductor manufacturing. Initially, wafer handling involved manual processes, which increased the risk of errors. Over time, technological advancements led to the creation of automated systems. These systems improved efficiency but still faced challenges in precision and reliability. The introduction of the Contiguous Wafer Boat marked a significant evolution. It combined advanced materials with innovative design to address these challenges. Today, you find it as an essential tool in modern semiconductor fabs, continuously evolving to meet industry demands.

Efficiency Improvements with the Contiguous Wafer Boat

Streamlining Production Processes

You can significantly streamline your semiconductor production processes by using the Contiguous Wafer Boat. This innovative tool allows you to handle wafers with greater precision and efficiency. You no longer need to worry about misalignment or damage during processing. The boat’s design ensures that wafers remain securely in place, reducing the risk of errors.

With the Contiguous Wafer Boat, you can accommodate various wafer sizes, making your production line more versatile. This adaptability means you can easily switch between different production requirements without extensive adjustments. As a result, you save time and resources, allowing you to focus on other critical aspects of manufacturing.

Reducing Downtime and Increasing Throughput

By integrating the Contiguous Wafer Boat into your operations, you can reduce downtime and increase throughput. The boat’s high-quality materials provide exceptional thermal stability and chemical resistance. This durability ensures that your equipment remains operational even in harsh environments. You experience fewer interruptions, which translates to more consistent production schedules.

Moreover, the Contiguous Wafer Boat enhances your ability to maintain high yield rates. Its precise alignment capabilities minimize defects, ensuring that more chips meet quality standards. You can produce more functional chips from each wafer, boosting your overall output. This efficiency not only improves your bottom line but also strengthens your competitive position in the market.

Cost-Effectiveness of the Contiguous Wafer Boat

Lowering Operational Costs

You can significantly lower your operational costs by integrating the Contiguous Wafer Boat into your semiconductor manufacturing process. This innovative tool reduces the risk of wafer damage, which minimizes waste and saves money. You no longer need to spend as much on replacing damaged wafers, which directly impacts your bottom line. The high-quality materials used in the Contiguous Wafer Boat ensure durability, reducing the frequency of replacements and maintenance. This longevity translates to fewer expenses over time, allowing you to allocate resources more efficiently.

Enhancing Resource Utilization

The Contiguous Wafer Boat enhances your resource utilization by optimizing wafer handling. Its design allows you to process wafers with greater precision, reducing errors and improving yield rates. You can produce more functional chips from each wafer, maximizing the use of your raw materials. This efficiency means you get more value from your existing resources, which is crucial in a competitive industry. By streamlining your production processes, you can focus on innovation and growth, rather than constantly managing inefficiencies.

Technological Advancements in the Contiguous Wafer Boat

Integration with Modern Manufacturing Technologies

You can enhance your semiconductor production by integrating the Contiguous Wafer Boat with modern manufacturing technologies. This tool seamlessly fits into automated systems, allowing you to streamline operations. You benefit from its compatibility with advanced robotics and precision equipment. This integration ensures that wafers are handled with utmost care, reducing the risk of errors.

The Contiguous Wafer Boat’s design supports real-time monitoring and data collection. You can track wafer conditions and adjust processes as needed. This capability helps you maintain high standards of quality and efficiency. By leveraging these technological advancements, you stay ahead in the competitive semiconductor industry.

Supporting Advanced Semiconductor Designs

The Contiguous Wafer Boat plays a crucial role in supporting advanced semiconductor designs. You can accommodate various wafer sizes and configurations, making it ideal for cutting-edge applications. Its precision alignment capabilities ensure that complex designs are executed flawlessly.

You can explore innovative semiconductor architectures with confidence. The boat’s robust construction withstands extreme conditions, allowing you to push the boundaries of design. As you develop new technologies, the Contiguous Wafer Boat provides the reliability and flexibility you need. This support empowers you to create next-generation semiconductors that meet evolving market demands.

Practical Applications of the Contiguous Wafer Boat

Use Cases in Various Semiconductor Manufacturing Stages

You can find the Contiguous Wafer Boat invaluable across different stages of semiconductor manufacturing. During the initial wafer preparation, it ensures precise alignment and secure handling. This accuracy is crucial for maintaining the integrity of the wafers as you move them through various processes. In the etching stage, the boat’s chemical resistance protects wafers from harsh environments, reducing the risk of damage. You benefit from its thermal stability during high-temperature processes like diffusion and oxidation, where maintaining wafer quality is essential.

In the lithography stage, the Contiguous Wafer Boat supports intricate patterning by holding wafers steady. This stability helps you achieve the fine details required in modern semiconductor designs. During the final testing and packaging stages, the boat continues to provide reliable support, ensuring that wafers remain undamaged and ready for market. By using the Contiguous Wafer Boat throughout these stages, you enhance efficiency and yield, ultimately improving your production outcomes.

Industry Adoption and Success Stories

Many leading semiconductor manufacturers have adopted the Contiguous Wafer Boat , recognizing its benefits. You can see its impact in companies that have reported increased throughput and reduced waste. These improvements translate to significant cost savings and higher profit margins. For instance, a major semiconductor fab integrated the Contiguous Wafer Boat into its production line and saw a 15% increase in yield rates. This success story highlights the boat’s ability to enhance operational efficiency.

Another company used the Contiguous Wafer Boat to streamline its manufacturing processes. The result was a 20% reduction in downtime, allowing the company to meet growing market demands more effectively. These examples demonstrate how the Contiguous Wafer Boat can transform your semiconductor production. By adopting this innovative tool, you join a growing list of industry leaders who have experienced tangible benefits. You position yourself to stay competitive in a rapidly evolving market.

Future Developments in Wafer Boat Design

Potential Innovations in Wafer Boat Design

You can expect exciting innovations in wafer boat design as technology advances. Engineers are exploring new materials that offer even greater thermal stability and chemical resistance. These materials could enhance the durability and performance of wafer boats, making them more efficient in extreme environments.

Designers are also focusing on improving the alignment capabilities of wafer boats. Enhanced precision in wafer positioning can lead to higher yield rates and better quality control. You might see wafer boats with advanced features like automated alignment systems, which can further streamline your production processes.

Another area of potential innovation is the customization of wafer boats. Manufacturers are working on designs that can be tailored to specific production needs. This flexibility allows you to optimize your manufacturing line for different wafer sizes and configurations, ensuring that you can meet diverse market demands.

Emerging Trends in Semiconductor Manufacturing

In the semiconductor industry, several trends are shaping the future of manufacturing. One significant trend is the move towards automation. You can see more fabs adopting automated systems to increase efficiency and reduce human error. The integration of wafer boats with these systems can enhance their effectiveness, allowing for seamless operations.

Another trend is the focus on sustainability. You might notice a growing emphasis on reducing waste and energy consumption in semiconductor production. Wafer boats that minimize damage and improve yield rates contribute to this goal by optimizing resource utilization.

The demand for smaller and more powerful chips is also driving innovation. As you work with increasingly complex semiconductor designs, the need for precise and reliable wafer handling becomes crucial. Wafer boats that support advanced designs and maintain high standards of quality will be essential in meeting these challenges.

By staying informed about these trends and potential innovations, you can position yourself to take advantage of new opportunities in the semiconductor industry. Embracing these developments can help you remain competitive and responsive to the evolving market landscape.

The Contiguous Wafer Boat offers numerous advantages in semiconductor production. You enhance efficiency and reduce costs by integrating this innovative tool into your operations. Its precision and reliability improve yield rates and streamline processes. As technology advances, you can expect further developments in wafer boat design. These innovations will continue to shape the industry, providing you with new opportunities to optimize your manufacturing capabilities. By staying informed and adopting these advancements, you position yourself to thrive in the competitive semiconductor market.

FAQ

What is a Contiguous Wafer Boat?

A Contiguous Wafer Boat is a specialized tool used in semiconductor manufacturing. You use it to securely hold and align wafers during processing. This ensures precision and reduces the risk of damage.

How does the Contiguous Wafer Boat improve efficiency?

The Contiguous Wafer Boat streamlines your production processes. It allows you to handle wafers with greater precision, reducing errors. This leads to fewer defects and higher yield rates.

Can the Contiguous Wafer Boat accommodate different wafer sizes?

Yes, the Contiguous Wafer Boat is versatile. You can use it for various wafer sizes and configurations. This adaptability makes it suitable for different production needs.

What materials are used in the Contiguous Wafer Boat?

The Contiguous Wafer Boat is crafted from high-quality materials. These materials provide thermal stability and chemical resistance. This makes the boat suitable for high-temperature and harsh chemical environments.

How does the Contiguous Wafer Boat reduce operational costs?

By minimizing wafer damage, the Contiguous Wafer Boat reduces waste. You spend less on replacing damaged wafers. Its durability also means fewer replacements and maintenance, lowering expenses over time.

Is the Contiguous Wafer Boat compatible with modern manufacturing technologies?

Yes, the Contiguous Wafer Boat integrates well with modern technologies. You can use it with automated systems and advanced robotics. This compatibility enhances your production efficiency.

What are the practical applications of the Contiguous Wafer Boat?

You can use the Contiguous Wafer Boat in various stages of semiconductor manufacturing. It ensures precise alignment and secure handling during wafer preparation, etching, lithography, and testing.

How has the Contiguous Wafer Boat evolved over time?

Initially, wafer handling involved manual processes. Over time, technological advancements led to automated systems. The Contiguous Wafer Boat combines advanced materials with innovative design, addressing precision and reliability challenges.

What are the future developments in wafer boat design?

You can expect innovations in materials and design. Engineers are exploring new materials for greater thermal stability and chemical resistance. Designers focus on improving alignment capabilities and customization options.

Why should I choose the Contiguous Wafer Boat from vet-china?

The Contiguous Wafer Boat from vet-china offers precision and reliability. You benefit from its high-quality construction and innovative design. By choosing this product, you invest in enhanced efficiency and reduced costs for your semiconductor manufacturing operations.