Wie die TAC-Beschichtung die Leistung von Fahrzeugteilen verbessert

TAC Die Beschichtung verbessert die Automobilteile durch die Verringerung der Reibung, die Verbesserung der Verschleißfestigkeit und die Erhöhung der Haltbarkeit, wodurch eine optimale Leistung bei Stress gewährleistet wird.

5 Gründe warum TAC-Beschichtung ein Muss ist – haben für Automobilkomponenten

TAC Die Beschichtung steigert Haltbarkeit, widersteht Korrosion und schützt die Automobilteile vor Verschleiß, UV-Strahlen und Chemikalien und sorgt für langfristige Leistung und Wert.

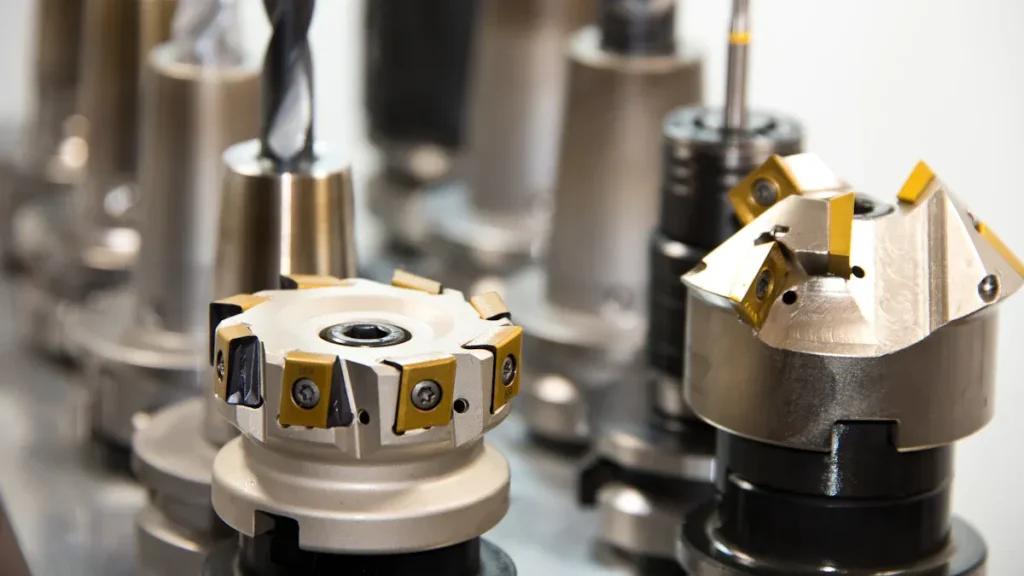

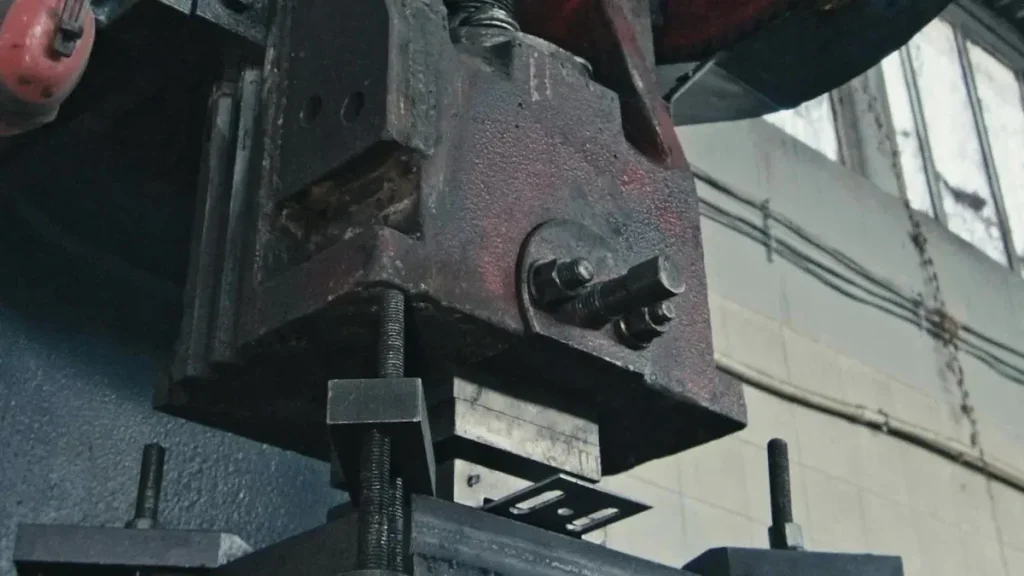

Die Spannrolle der TAC Beschichtung in mechanischen Bearbeitungsanwendungen

TAC Beschichtung verbessert die Bearbeitung mit überragender Haltbarkeit, thermischer Stabilität und chemischer Beständigkeit, so dass es ideal für Luft- und Raumfahrt, Automotive und Elektronik.

10 Wege TAC Beschichtung wird heute in der mechanischen Bearbeitung verwendet

Entdecken Sie 10 innovative Wege TAC Beschichtung verbessert die Bearbeitung durch Verbesserung der Werkzeugstabilität, Wärmebeständigkeit, Schneideffizienz und Präzision in modernen Prozessen.

Anwendungen der TAC Beschichtung, die mechanische Bearbeitung neu definieren

TAC Beschichtung verbessert die Bearbeitung mit überragender Haltbarkeit, Verschleißfestigkeit und thermische Stabilität, die Neudefinition von Schneidwerkzeugen, Präzisionsbearbeitung und mehr.