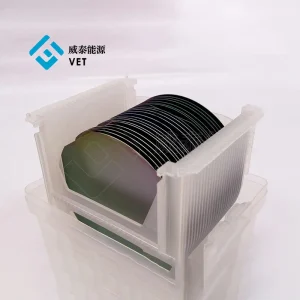

CVD TaC Coatings, or chemical vapor deposition tantalum carbide coatings, provide exceptional hardness and thermal resistance. Industries such as aerospace and electronics rely on these coatings for enhanced durability and performance. The market for TaC Coatings continues to expand due to rising demand for advanced materials. Emerging technologies like cvd sic coating further drive innovation in this sector.

Wichtigste Erkenntnisse

- CVD TaC Coatings are important for aerospace and electronics.

- They are very hard and can handle high heat well.

- The market for these coatings will grow a lot by 2030.

- This is because more people need better materials and new tech.

- Countries in Asia-Pacific are helping this growth the most.

- Industrial growth and research investments are making this possible.

Market Overview

Current Market Size and Valuation

The global market for CVD TaC Coatings has witnessed steady growth in recent years. As of 2023, the market’s valuation stands at approximately $XX billion, reflecting its increasing adoption across various industries. This growth stems from the material’s unique properties, including exceptional hardness, thermal resistance, and chemical stability. These characteristics make it indispensable in high-performance applications. The aerospace and electronics sectors, in particular, have contributed significantly to the current market size, as manufacturers seek advanced coatings to enhance product durability and efficiency.

Projected Growth and CAGR

Between 2024 and 2030, the CVD TaC Coatings market is projected to grow at a compound annual growth rate (CAGR) of XX%. This robust growth trajectory highlights the rising demand for advanced materials in industries such as automotive, energy, and medical devices. Increasing investments in research and development further accelerate market expansion. Analysts predict that emerging economies in Asia-Pacific will play a pivotal role in driving this growth, as industrialization and technological advancements continue to gain momentum in the region.

Key Industries Driving Demand for CVD TaC Coatings

Several industries drive the demand for CVD TaC Coatings. The aerospace sector relies on these coatings to improve the performance and lifespan of critical components exposed to extreme conditions. In the electronics industry, the coatings provide superior protection for semiconductor equipment, ensuring reliability and precision. Additionally, the energy sector benefits from their application in high-temperature environments, such as gas turbines and nuclear reactors. The medical field also shows growing interest, particularly in surgical tools and implants, where durability and biocompatibility are essential.

Market Dynamics

Driving Factors Behind Market Growth

The increasing demand for high-performance materials drives the growth of the CVD TaC Coatings market. Industries such as aerospace and electronics require coatings that offer superior hardness, thermal resistance, and chemical stability. These properties make CVD TaC Coatings essential for applications in extreme environments. The rapid industrialization in emerging economies, particularly in Asia-Pacific, further accelerates market expansion. Governments and private organizations are investing heavily in research and development to enhance coating technologies. This focus on innovation ensures the continuous improvement of product quality and performance, fueling market growth.

Restraining Factors Impacting the Market

Despite its promising growth, the CVD TaC Coatings market faces several challenges. The high cost of raw materials and production processes limits its adoption, especially among small and medium-sized enterprises. Additionally, the complexity of the chemical vapor deposition process requires specialized equipment and expertise, which increases operational costs. Environmental concerns related to the use of certain chemicals in the coating process also pose regulatory challenges. These factors collectively hinder the market’s growth potential, particularly in regions with stringent environmental regulations.

Emerging Trends in CVD TaC Coatings

Several trends are shaping the future of the CVD TaC Coatings market. The development of eco-friendly coating processes is gaining traction as industries strive to meet sustainability goals. Advanced manufacturing techniques, such as additive manufacturing, are integrating CVD TaC Coatings to enhance product performance. The growing adoption of coatings in the medical sector, particularly for surgical tools and implants, highlights the expanding application scope. Furthermore, the increasing focus on nanotechnology is paving the way for innovative coating solutions with enhanced properties.

Market Segmentation

Segmentation by Type

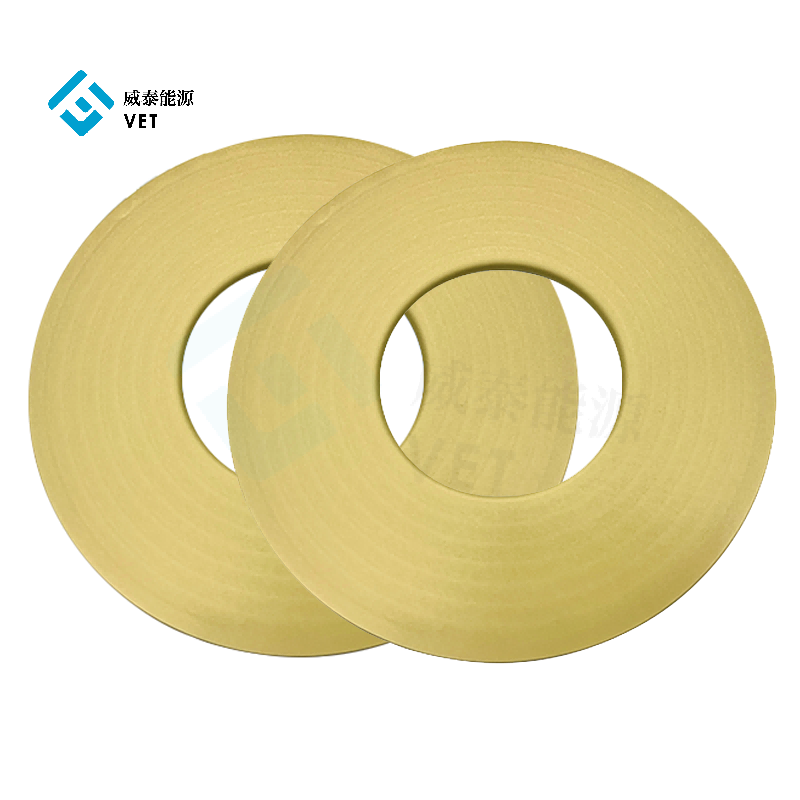

The CVD TaC Coatings market can be segmented based on the type of coating. These include single-layer coatings and multi-layer coatings. Single-layer coatings are widely used in applications requiring basic protection and durability. Multi-layer coatings, on the other hand, offer enhanced performance by combining different material properties. They are particularly suitable for industries that demand superior resistance to wear, corrosion, and extreme temperatures. The choice between these types depends on the specific requirements of the end-use application.

Segmentation by Application

Applications of CVD TaC Coatings span across diverse industries. In aerospace, these coatings are applied to turbine blades and other components to improve thermal resistance. The electronics sector uses them for semiconductor equipment, ensuring precision and reliability. In the energy industry, they are critical for high-temperature environments such as gas turbines and nuclear reactors. The medical field also benefits from these coatings, particularly in surgical tools and implants, where durability and biocompatibility are essential. Each application highlights the versatility and importance of these coatings in modern technology.

Regional Analysis of the Market

The market for CVD TaC Coatings exhibits significant regional variations. North America leads in adoption due to its advanced aerospace and electronics industries. Europe follows closely, driven by its focus on sustainable energy solutions and high-performance materials. The Asia-Pacific region is emerging as a key growth area, fueled by rapid industrialization and technological advancements in countries like China, Japan, and India. Latin America and the Middle East also show potential, with increasing investments in energy and infrastructure projects. These regional dynamics underscore the global appeal and growing demand for CVD TaC Coatings.

Competitive Landscape

Major Players in the CVD TaC Coatings Market

The CVD TaC Coatings market features several prominent players who dominate through their expertise and extensive product portfolios. Companies such as Praxair Surface Technologies, Oerlikon Balzers, and IHI Ionbond AG lead the industry. These organizations have established a strong global presence by catering to diverse industries, including aerospace, electronics, and energy. Emerging players from Asia-Pacific, such as Advanced Coating Solutions and Hunan Boyun New Materials, are also gaining traction due to their cost-effective solutions and regional market focus. The competitive landscape reflects a mix of established giants and innovative newcomers.

Strategies and Innovations by Key Companies

Leading companies in the CVD TaC Coatings market employ various strategies to maintain their competitive edge. Many focus on strategic partnerships and collaborations to expand their technological capabilities. For instance, partnerships with research institutions enable the development of advanced coating solutions. Companies also invest heavily in R&D to create eco-friendly and high-performance coatings. Additionally, market leaders adopt customer-centric approaches, offering tailored solutions to meet specific industrial requirements. These strategies ensure sustained growth and market relevance.

Technological Advancements in CVD TaC Coatings

Technological advancements drive innovation in the CVD TaC Coatings market. Recent developments include the integration of nanotechnology to enhance coating properties, such as wear resistance and thermal stability. Automation in the chemical vapor deposition process has improved production efficiency and reduced costs. Furthermore, advancements in multi-layer coating techniques have expanded the application scope across industries. These innovations highlight the industry’s commitment to meeting evolving market demands.

Future Outlook

Opportunities for Stakeholders in the Market

The CVD TaC Coatings market offers significant opportunities for stakeholders across various industries. Manufacturers can capitalize on the growing demand for advanced materials in aerospace, electronics, and energy sectors. By investing in research and development, companies can create innovative coatings that cater to emerging applications, such as medical implants and nanotechnology. Governments in developing regions are also providing incentives for industrial advancements, creating a favorable environment for market expansion. Collaboration between industry leaders and academic institutions can further drive innovation, enabling stakeholders to stay ahead in a competitive landscape.

Challenges and Risks in the Industry

Despite its potential, the industry faces several challenges that could hinder growth. The high cost of production remains a significant barrier, particularly for small and medium-sized enterprises. Regulatory restrictions on chemical usage in coating processes add complexity to operations, especially in regions with stringent environmental laws. Additionally, the need for specialized equipment and expertise increases operational expenses, limiting market accessibility. Economic uncertainties and fluctuating raw material prices also pose risks, potentially impacting the profitability of key players.

Long-Term Potential of CVD TaC Coatings

The long-term potential of CVD TaC Coatings lies in their versatility and ability to meet the demands of evolving industries. As technology advances, these coatings will play a crucial role in enhancing the performance of high-precision components. Their application in sustainable energy solutions, such as solar panels and wind turbines, highlights their relevance in addressing global energy challenges. With continuous innovation and strategic investments, the market is poised to achieve sustained growth, solidifying its position as a cornerstone of modern material science.

The CVD TaC Coatings market demonstrates robust growth driven by technological advancements and increasing industrial demand. Stakeholders can leverage opportunities in emerging applications while addressing challenges like high production costs.

Monitoring market trends ensures businesses stay competitive and adapt to evolving industry needs, securing long-term success in this dynamic sector.