Sie stehen vor einer wachsenden Notwendigkeit, grüne Produktion in der Produktion zu übernehmen CVD TaC Beschichtungen. Traditionelle Methoden schädigen die Umwelt und die Abfallressourcen. Nachhaltige Strategien reduzieren Emissionen, sparen Energie und senken Kosten. TaC-Beschichtungen, in hochleistungsindustrien verwendet, zeigen, wie CVD TaC Beschichtungstechnologie kann umweltfreundliche innovation vorantreiben und dabei eine überlegene materialleistung erhalten.

Wichtigste Erkenntnisse

- Verwendung energiesparverfahren wie plasmaverstärkte CVD, um Energie zu sparen und gute Beschichtungsqualität zu erhalten.

- Verwenden Sie saubere Energie, wie Solar oder Wind, um den Kohlenstoffverbrauch zu reduzieren und Energiekosten zu senken.

- Arbeite mit Unternehmen und Wissenschaftlern, um neue Wege zu finden CVD TaC Beschichtungen mehr umweltfreundlich.

Überblick über CVD TaC Coatings

CVD definieren TaC Beschichtungen

CVD-TaC-Beschichtungen oder chemische Aufdampfung Tantalcarbid-Beschichtungen sind dünne Schutzschichten auf Oberflächen aufgebracht. Diese Beschichtungen verwenden einen chemischen Aufdampfprozess, um eine dauerhafte und hitzebeständige Barriere zu schaffen. Sie können sich darauf verlassen, um die Leistung von Materialien in extremen Umgebungen zu verbessern. Tantalcarbid, bekannt für seinen hohen Schmelzpunkt und Härte, macht diese Beschichtungen ideal für anspruchsvolle Anwendungen.

Anwendungen in der Hochleistungsindustrie

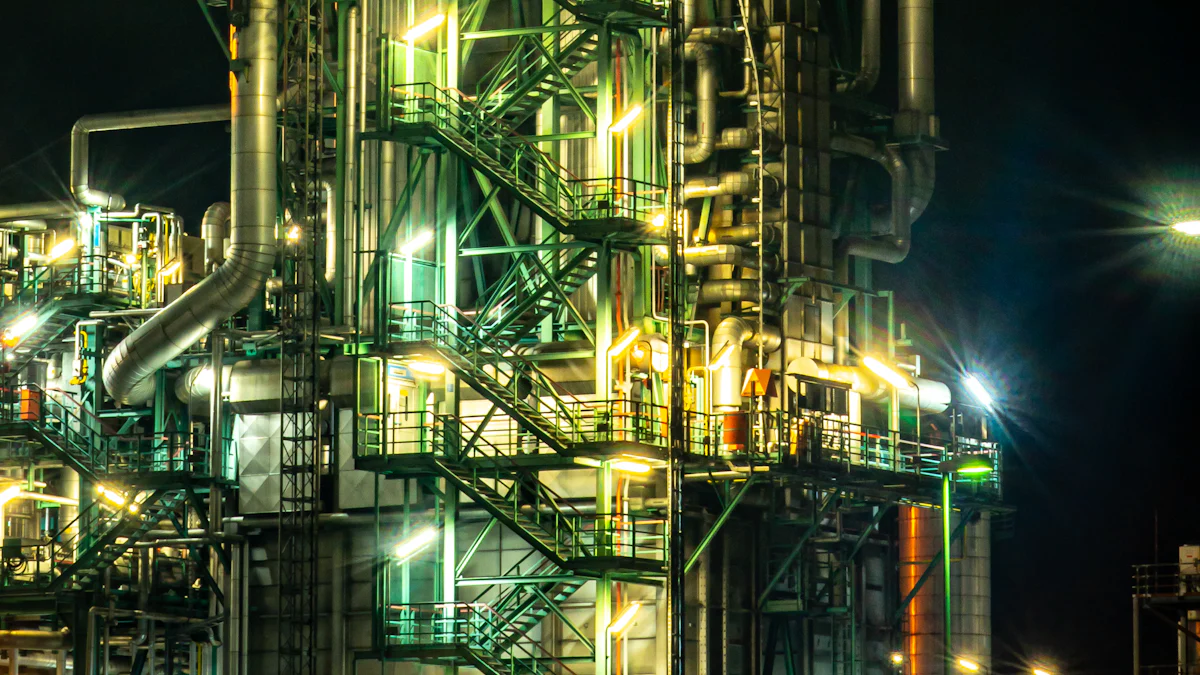

Sie finden CVD TaC Beschichtungen in Industrien, die Materialien benötigen, um extremen Bedingungen standzuhalten. Aerospace-Unternehmen nutzen sie, um Bauteile zu schützen, die hohen Temperaturen ausgesetzt sind. In der halbleiterindustrie, diese Beschichtungen verbessern die Haltbarkeit von Werkzeugen, die in der Herstellung verwendet werden. Sie spielen auch eine kritische Rolle in der Kernenergie, wo sie Oberflächen vor Korrosion und Strahlenschäden schützen. Ihre Vielseitigkeit stellt sicher, dass sie den Bedürfnissen verschiedener Hochleistungssektoren gerecht werden.

Umweltbelange in der traditionellen Fertigung

Traditionelle Methoden zur Herstellung von CVD TaC Beschichtungen oft umwelt schaden. Diese Prozesse verbrauchen große Mengen an Energie und tragen zu Treibhausgasemissionen bei. Gefährliche Nebenprodukte wie giftige Gase können auch Risiken für Ökosysteme und menschliche Gesundheit darstellen. Sie können feststellen, dass das Abfallmanagement in der konventionellen Fertigung weiterhin eine bedeutende Herausforderung darstellt. Die Bewältigung dieser Bedenken ist für die Schaffung einer nachhaltigeren Zukunft für CVD TaC Beschichtungen unerlässlich.

Herausforderungen in der Green Manufacturing für CVD TaC Coatings

Hoher Energieverbrauch in CVD-Prozessen

Sie können feststellen, dass chemische Verdampfungsprozesse (CVD) erhebliche Energie erfordern. Die hohen Temperaturen, die zur Abscheidung von Tantalcarbidbeschichtungen benötigt werden, führen oft zu einem übermäßigen Energieeinsatz. Dieser Energiebedarf erhöht die Betriebskosten und trägt zu Kohlenstoffemissionen bei. Viele Hersteller kämpfen, um Wege zu finden, um den Energieverbrauch zu reduzieren, ohne die Qualität der CVD TaC Beschichtungen zu beeinträchtigen. Die Nutzung energieeffizienter Technologien, wie Plasma-verstärkte CVD, kann Ihnen dabei helfen, diese Herausforderung anzugehen.

Verwalten von Gefahren Nebenprodukte

CVD-Prozesse produzieren oft gefährliche Nebenprodukte, darunter giftige Gase und chemische Abfälle. Diese Nebenprodukte können der Umwelt schaden und Risiken für die menschliche Gesundheit darstellen. Sie müssen effektive Abfallmanagementsysteme implementieren, um diese Auswirkungen zu minimieren. So können beispielsweise mit fortschrittlichen Filtrationssystemen schädliche Emissionen erfasst werden, bevor sie in die Atmosphäre entweichen. Recycling chemischer Vorstufen ist eine weitere Strategie, die Abfall und fördert nachhaltigkeit.

Balancing Materialleistung mit Eco-Friendliness

Vielleicht finden Sie es herausfordernd, die hohe Leistung von CVD TaC Beschichtungen bei der Annahme umweltfreundlicher Praktiken. Die außergewöhnlichen Eigenschaften von Tantalcarbid wie Hitzebeständigkeit und Haltbarkeit sind für anspruchsvolle Anwendungen unerlässlich. Allerdings kann die Beschaffung nachhaltiger Materialien oder die Änderung des Abscheidungsprozesses diese Eigenschaften manchmal beeinflussen. Ein Gleichgewicht erfordert innovative Ansätze, wie die Entwicklung alternativer Materialien oder die Optimierung von Prozessparametern.

Tipp: Mit der Zusammenarbeit mit Forschern und Branchenexperten können Sie Lösungen entdecken, die sowohl Leistung als auch Nachhaltigkeit steigern.

Grüne Fertigungsstrategien für CVD TaC Coatings

Energieeffiziente Depositionstechniken

Sie können energieeffiziente Abscheidetechniken annehmen, um die Umweltauswirkungen der Produktion zu reduzieren CVD TaC Beschichtungen. Eine solche Methode ist eine plasmaverstärkte chemische Aufdampfung (PECVD). Es verwendet Plasma, um die zur Beschichtung erforderliche Temperatur zu senken. Dieser Ansatz reduziert den Energieverbrauch bei gleichbleibender Beschichtungsqualität. Eine andere Möglichkeit besteht darin, Prozessparameter wie Gasdurchflussraten und Reaktionszeiten zu optimieren. Diese Anpassungen minimieren den Energieeinsatz ohne Beeinträchtigung der Leistung. Durch die Fokussierung auf Energieeffizienz tragen Sie zu einem nachhaltigeren Herstellungsprozess bei.

Integration erneuerbarer Energien in die Produktion

Die Umstellung auf erneuerbare Energiequellen kann den CO2-Fußabdruck der CVD TaC-Beschichtung deutlich senken. Solarpaneele und Windenergieanlagen sorgen für saubere Energie für Kraftwerke. Sie können auch Energiespeicher wie Batterien erkunden, um eine stetige Versorgung mit erneuerbaren Energien sicherzustellen. Die Integration dieser Technologien in Ihren Betrieb reduziert die Abhängigkeit von fossilen Brennstoffen. Diese Verschiebung profitiert nicht nur der Umwelt, sondern senkt auch langfristige Energiekosten. Erneuerbare Energieannahme zeigt Ihr Engagement für Nachhaltigkeit.

Recycling und Abfallminimierung Praktiken

Recycling und Abfallminimierung spielen eine entscheidende Rolle bei der grünen Fertigung. Sie können chemische Vorläufer, die im CVD-Prozess verwendet werden, recyceln, um Materialabfälle zu reduzieren. Fortgeschrittene Filtrationssysteme erfassen und wiederverwenden Nebenprodukte und machen Abfall zu wertvollen Ressourcen. Durch die Durchführung von Closed-Loop-Systemen wird sichergestellt, dass Materialien innerhalb des Produktionszyklus zirkulieren. Diese Praktiken reduzieren den Bedarf an Rohstoffen und minimieren Umweltschäden. Durch die Priorisierung des Recyclings schaffen Sie einen effizienteren und umweltfreundlicheren Produktionsprozess für CVD TaC Beschichtungen.

Innovationen für nachhaltige Entwicklung

Ausschreibungen im CVD-Prozessdesign

Sie können erkunden weiterentwicklungen im Prozessdesign von CVD die Produktion nachhaltig zu gestalten. Moderne Innovationen konzentrieren sich auf die Optimierung der Reaktionsbedingungen zur Reduzierung des Energieverbrauchs. So haben Forscher Niederdruck-CVD-Systeme entwickelt, die bei niedrigeren Temperaturen effizient arbeiten. Diese Systeme sparen nicht nur Energie, sondern verbessern auch die Beschichtungsgleichmäßigkeit. Ein weiterer Durchbruch beinhaltet die Verwendung fortschrittlicher rechnergestützter Modellierung. Diese Technologie ermöglicht es Ihnen, Prozessergebnisse vorherzusagen und Abfälle während der Produktion zu minimieren. Durch die Annahme dieser Fortschritte können Sie die Effizienz und Nachhaltigkeit der CVD TaC-Beschichtung verbessern.

Entwicklung nachhaltiger Beschichtungsmaterialien

Entwicklung nachhaltige beschichtungsstoffe ist eine weitere Schlüsselinnovation. Sie können mit alternativen Vorläufern experimentieren, die weniger giftig und umweltfreundlicher sind. Beispielsweise bieten biobasierte Vorläufer aus erneuerbaren Ressourcen eine grünere Option. Zusätzlich können Sie sich darauf konzentrieren, die Menge an Tantalcarbid zu reduzieren, ohne die Leistung zu beeinträchtigen. Dünnschicht-Technologien ermöglichen es Ihnen, dies zu erreichen, indem Sie ultradünne und dennoch langlebige Beschichtungen erstellen. Diese Bemühungen tragen dazu bei, die Umweltauswirkungen von Materialien zu reduzieren und gleichzeitig die hohen Anforderungen an CVD TaC Beschichtungen zu erfüllen.

Branchenkollaboration für Green Solutions

Die Zusammenarbeit innerhalb der Branche kann die Annahme von grünen Lösungen beschleunigen. Sie können mit anderen Herstellern, Forschungseinrichtungen und Politikern zusammenarbeiten, um Wissen und Ressourcen zu teilen. Gemeinsame Initiativen führen oft zur Entwicklung innovativer Technologien und nachhaltiger Praktiken. Zum Beispiel können branchenweite Recyclingprogramme Ihnen helfen, Abfälle effektiver zu verwalten. Auch die Zusammenarbeit erleichtert die Festlegung einheitlicher Leitlinien für die umweltfreundliche Fertigung. Durch die Zusammenarbeit können Sie sinnvolle Veränderungen vorantreiben und Nachhaltigkeit im gesamten Sektor fördern.

Politik- und Regulierungsrahmen

Incentives for Sustainable Manufacturing

Regierungen und Organisationen bieten Anreize für eine nachhaltige Fertigung. Sie können von Steuergutschriften, Zuschüssen oder Subventionen profitieren, wenn Sie umweltfreundliche Praktiken annehmen. Diese Anreize verringern die finanzielle Belastung der Umstellung auf grüne Technologien. Beispielsweise ist die Installation erneuerbarer Energiesysteme oder die Modernisierung energieeffizienter Geräte für solche Programme oft qualifiziert.

Tipp: Überprüfen Sie lokale und internationale Programme, die nachhaltige Initiativen belohnen. Diese Möglichkeiten können Ihnen helfen, Kosten zu kompensieren und die Rentabilität zu verbessern.

Darüber hinaus zeigen Zertifizierungen wie ISO 14001 Ihr Engagement für das Umweltmanagement. Diese Zertifizierungen zu erreichen, verbessert nicht nur Ihren Ruf, sondern öffnet auch Türen für neue Märkte. Kunden bevorzugen zunehmend Unternehmen, die Nachhaltigkeit priorisieren.

Schaffung von Umweltstandards für CVD-Prozesse

Klar umweltnormen führen Sie bei der Annahme grüner Praktiken. Regelorgane setzen häufig Grenzwerte für Emissionen, Energienutzung und Abfallerzeugung. Nach diesen Standards wird die Einhaltung gewährleistet und Umweltschäden reduziert. Sie müssen beispielsweise gefährliche Nebenprodukte während der CVD-Prozesse überwachen und kontrollieren.

Anmerkung: Die Aktualisierung der Vorschriften hilft Ihnen, Strafen zu vermeiden und betriebliche Effizienz zu erhalten.

Industriespezifische Leitlinien fördern auch die Konsistenz. Durch die Einhaltung dieser Standards tragen Sie zu einem kollektiven Streben nach Nachhaltigkeit bei.

Unterstützung der Forschung in Green Technologies

Die Investition in die Forschung treibt Innovation in der grünen Fertigung an. Sie können mit Universitäten oder Forschungseinrichtungen zusammenarbeiten, um umweltfreundliche Lösungen zu entwickeln. Beispielsweise kann die Erkundung alternativer Materialien oder die Optimierung von CVD-Prozessen zu Durchbrüchen führen.

Regierungen finanzieren oft Forschungsprojekte, die auf Nachhaltigkeit ausgerichtet sind. Die Inanspruchnahme dieser Zuschüsse kann Ihren Fortschritt beschleunigen. Der Austausch von Erkenntnissen mit der Industrie fördert die Zusammenarbeit und beschleunigt die Einführung grüner Technologien.

Emoji Insight: 🌱 Die Forschung prägt morgen eine grünere.

Durch die Unterstützung der Forschung bleiben Sie in der wettbewerbsfähigen Landschaft und tragen zu globalen Nachhaltigkeitszielen bei.

Die grüne Fertigung für CVD TaC Coatings sorgt für eine nachhaltige Zukunft. Sie reduzieren Umweltschäden und Betriebskosten bei gleichzeitiger Aufrechterhaltung der Materialleistung. Diese Praktiken profitieren von Industrien und dem Planeten. Machen Sie jetzt Action. Vorrangige umweltfreundliche Lösungen und Zusammenarbeit mit politischen Entscheidungsträgern, um einen sinnvollen Wandel in der Beschichtungsbranche voranzutreiben.

FAQ

Was macht CVD TaC Beschichtungen ökologisch bedeutsam?

CVD TaC Beschichtungen abfall reduzieren und die Materialeffizienz verbessern. Ihre Haltbarkeit minimiert den Bedarf an häufigen Ersetzungen, senkt den Ressourcenverbrauch und Umweltauswirkungen.

Wie können Sie den Energieeinsatz in CVD-Prozessen reduzieren?

Sie können energieeffiziente Techniken wie plasmagestützte CVD annehmen. Durch die Optimierung der Reaktionsbedingungen und die Integration erneuerbarer Energiequellen wird auch der Energieverbrauch reduziert.

Gibt es Kostenvorteile für die grüne Fertigung?

Ja, grüne fertigung senkt betriebskosten. Recycling-Materialien, die Energienutzung und die Annahme erneuerbarer Energiequellen sparen Geld und verbessern die Nachhaltigkeit.