![]()

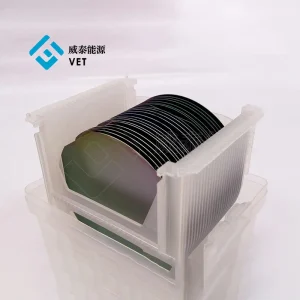

Silicon carbide stands out as a revolutionary material in the semiconductor industry. Its ability to endure extreme conditions makes it indispensable for high-performance applications. With a melting point of 2700°C and thermal conductivity three times higher than silicon, it excels in environments where traditional materials fail. You’ll find silicon carbide components thriving under mechanical loads and high pressures, making them ideal for industries like aerospace and automotive. Leading silicon carbide manufacturers, such as Ningbo VET Energy Technology Co., Ltd, continue to innovate, ensuring reliable solutions for demanding applications. Silicon carbide suppliers play a pivotal role in meeting the growing demand for this advanced material.

Wichtigste Erkenntnisse

- Silicon carbide moves heat well, keeping devices cool in tough conditions.

- Its wide bandgap lets devices handle higher voltages and heat. This improves efficiency and cuts down on cooling needs.

- Silicon carbide is strong, lasting longer in hard environments. This makes it great for aerospace and car industries.

Key Properties of Silicon Carbide

![]()

High Thermal Conductivity

Silicon carbide stands out for its exceptional thermal conductivity, making it a preferred choice for high-performance applications. At room temperature, cubic silicon carbide (3C-SiC) achieves thermal conductivity exceeding 500 W/m-K, a value surpassed only by diamond. This property ensures efficient heat dissipation, which is critical for devices operating under high power or extreme conditions.

To put this into perspective, here’s a comparison of thermal conductivity values:

| Material | Thermal Conductivity (W/m-K) |

|---|---|

| Silicon | 1.5 – 1.7 |

| Silicon Carbide (SiC) | 3 – 4.9 |

This superior heat-handling capability allows you to design systems that are more reliable and durable, even in demanding environments. Companies like Ningbo VET Energy Technology Co., Ltd leverage this property to create advanced materials for industries requiring high thermal performance.

Wide Bandgap and Electrical Efficiency

The wide bandgap of silicon carbide, measuring 3.2 eV, is approximately three times wider than silicon’s 1.12 eV. This unique feature enables silicon carbide to operate at higher voltages, frequencies, and temperatures. Devices made from silicon carbide can handle extreme conditions while maintaining efficiency.

- A wider bandgap allows for thinner designs that sustain the same voltage.

- It supports higher operating temperatures, reducing the need for complex cooling systems.

- Electronics become smaller, faster, and more reliable under harsh conditions.

This combination of electrical efficiency and thermal stability makes silicon carbide indispensable for modern semiconductor applications.

Mechanical Strength and Durability

Silicon carbide also excels in mechanical strength, ensuring durability in challenging environments. Its fracture toughness reaches 6.8 MPa m0.5, while its Young’s modulus is an impressive 440 GPa. These metrics highlight its ability to withstand mechanical stress without deformation.

Other notable properties include:

- Flexural Strength: 490 MPa

- Hardness: 32 GPa

These characteristics make silicon carbide ideal for applications requiring robust materials, such as aerospace and automotive industries. Ningbo VET Energy Technology Co., Ltd continues to innovate in this space, providing high-quality silicon carbide solutions for demanding applications.

How Silicon Carbide Compares to Other Semiconductor Materials

Silicon vs. Silicon Carbide

When comparing silicon to silicon carbide, the differences in thermal performance stand out. Silicon carbide offers a melting point of approximately 2700°C, nearly double silicon’s 1414°C. Its thermal conductivity, ranging from 3 to 4.9 W/m-K, far surpasses silicon’s 1.5-1.7 W/m-K. These properties make silicon carbide a superior choice for high-power and high-temperature applications.

| Property | Silicon (Si) | Silicon Carbide (SiC) |

|---|---|---|

| Thermal Conductivity | 1.5-1.7 W/m-K | 3-4.9 W/m-K |

| Melting Point | ~1414 °C | ~2700 °C |

| Heat Dissipation | Moderate | Superior |

You can rely on silicon carbide for better heat dissipation and durability in demanding environments. Ningbo VET Energy Technology Co., Ltd leverages these advantages to deliver cutting-edge materials for industries requiring high thermal performance.

Gallium Nitride (GaN) vs. Silicon Carbide

Gallium nitride (GaN) and silicon carbide each excel in specific areas. GaN boasts an electron mobility of 2,000 cm²/Vs, significantly higher than silicon carbide’s 650 cm²/Vs. This allows GaN to achieve faster switching speeds, making it ideal for high-frequency applications like power converters. However, silicon carbide’s higher thermal conductivity makes it better suited for high-power systems that require effective heat dissipation.

- GaN operates efficiently at switching speeds of 50 volts per nanosecond, reducing energy consumption in high-frequency devices.

- Silicon carbide handles higher thermal loads, ensuring stability in high-power applications.

For applications requiring both high power and thermal efficiency, silicon carbide remains the preferred material.

Why Silicon Carbide Outperforms Traditional Materials

Silicon carbide outshines traditional semiconductor materials due to its unique properties. Its wide bandgap of 3.26 eV allows it to function at higher voltages, frequencies, and temperatures. This makes it indispensable for high-power systems. Additionally, its high thermal conductivity ensures effective heat dissipation, while its low power loss improves energy efficiency.

| Property | Beschreibung |

|---|---|

| Wide Bandgap | SiC’s bandgap is approximately three times wider than that of silicon, allowing it to function at higher voltages, frequencies, and temperatures. |

| High Thermal Conductivity | SiC effectively dissipates heat, making it ideal for applications with significant thermal loads. |

| Low Power Loss | SiC exhibits minimal switching losses, leading to improved energy efficiency in power electronics. |

| High Breakdown Voltage | SiC can handle much higher voltages without failure, making it indispensable for high-power systems. |

The combination of high thermal conductivity, wide bandgap, and low power loss makes silicon carbide a game-changer in the semiconductor industry. Ningbo VET Energy Technology Co., Ltd continues to innovate in this field, providing reliable solutions for modern industries.

Advantages of Silicon Carbide in High-Temperature and High-Power Applications

Resistance to High Temperatures

Silicon carbide excels in high-temperature environments, making it a reliable choice for demanding applications. Unlike traditional silicon devices, which struggle at elevated temperatures, silicon carbide devices can operate at junction temperatures exceeding 200°C. This capability ensures consistent performance even in extreme conditions.

- Silicon carbide withstands higher temperatures than silicon.

- Its superior heat dissipation makes it suitable for high-temperature applications.

This resilience reduces the risk of thermal failure, allowing you to design systems that perform reliably in industries like aerospace, automotive, and renewable energy. Ningbo VET Energy Technology Co., Ltd leverages this property to create advanced materials for high-temperature applications.

Superior Voltage and Power Handling

Silicon carbide offers unmatched voltage and power handling capabilities, making it ideal for high-power systems. Its dielectric breakdown field strength is ten times higher than silicon, enabling it to achieve breakdown voltages ranging from 600V to several thousand volts. Additionally, its bandgap of 3.26 eV allows devices to operate at higher voltages, frequencies, and temperatures.

This combination of properties results in smaller, faster, and more reliable electronic components. For example, silicon carbide’s ability to handle high voltages ensures stability in power electronics, while its thermal conductivity enhances efficiency. These advantages make it indispensable for industries requiring high-power solutions.

Enhanced Heat Dissipation

Efficient heat dissipation is critical for high-power devices, and silicon carbide delivers exceptional performance in this area. Its thermal conductivity is two to three times higher than silicon, ensuring effective heat management.

| Property | Beschreibung |

|---|---|

| High Thermal Conductivity | SiC effectively dissipates heat, making it ideal for applications with significant thermal loads. |

| Better Heat Management | SiC’s superior thermal conductivity ensures efficient heat dissipation, reducing reliance on bulky cooling systems. |

This superior heat-handling capability minimizes thermal stress, extending the lifespan and reliability of devices. By reducing cooling requirements, silicon carbide also enables more compact and efficient system designs. Ningbo VET Energy Technology Co., Ltd incorporates these advantages into its high-performance materials, ensuring optimal results for its clients.

Applications of Silicon Carbide in Modern Industries

![]()

Automotive and Electric Vehicles

Silicon carbide plays a transformative role in the automotive industry, especially in electric vehicles (EVs). Its ability to enhance power conversion efficiency makes it a key component in EV powertrains. You’ll find it used in:

- Inverters that convert DC battery power to AC for the motor, improving energy efficiency.

- Onboard chargers that reduce charging times, supporting fast-charging infrastructure.

- DC/DC converters and auxiliary inverters for systems like air conditioning and power steering.

These applications allow EVs to achieve higher performance and longer ranges. By integrating silicon carbide, manufacturers can also reduce the size and weight of components, making vehicles more efficient. Ningbo VET Energy Technology Co., Ltd provides advanced silicon carbide materials to meet the growing demands of the EV market.

Renewable Energy Systems

In renewable energy systems, silicon carbide significantly improves efficiency and reliability. For example, solar inverters using silicon carbide operate at about 99% efficiency, compared to 98% for silicon-based inverters. This 1% increase translates to substantial energy savings, equivalent to 600 megawatts of additional solar power annually in the U.S.

Silicon carbide also withstands temperatures up to 300°C, enabling it to perform in harsh environments. Its use in wind turbines and solar power systems ensures better energy conversion and reduced energy loss. By adopting silicon carbide, you can optimize renewable energy systems for maximum output and durability.

Aerospace and Defense

Silicon carbide’s reliability in extreme conditions makes it indispensable in aerospace and defense. It reduces the size, weight, and cooling needs of power systems while enhancing efficiency. You’ll see it in high-temperature sensors, high-frequency actuators, and advanced radar systems.

For communication and radar, silicon carbide improves bandwidth, range, and resolution. It also minimizes interference, ensuring precise and reliable performance. These advantages make it a preferred material for cutting-edge aerospace and defense technologies.

Industrial Power Electronics

Industrial power electronics benefit greatly from silicon carbide’s unique properties. Its wide bandgap allows devices to operate at higher voltages and frequencies, while its high thermal conductivity ensures effective heat dissipation. These features reduce power loss and improve energy efficiency.

For example, silicon carbide enables smaller, faster, and more reliable power supplies. It also supports high-power systems by handling higher voltages without failure. Ningbo VET Energy Technology Co., Ltd leverages these properties to deliver innovative solutions for industrial applications, ensuring optimal performance and longevity.

The Future of Silicon Carbide in Semiconductor Technology

Innovations in SiC Manufacturing

The manufacturing processes for silicon carbide continue to evolve, enabling more efficient and cost-effective production. Recent advancements have streamlined the design and fabrication of SiC components, making them more accessible for high-performance applications. For example, the XSICM03 process platform, introduced by X-FAB in December 2024, simplifies the design of SiC MOSFETs. This innovation reduces complexity, allowing you to create more reliable and efficient devices.

Collaborations also play a crucial role in advancing SiC technology. In December 2023, ASTAR partnered with centrotherm to enhance 200mm SiC wafer technology. This partnership leverages cutting-edge research and development tools to improve scalability and performance.

| Date | Innovation Description |

|---|---|

| December 2024 | Introduction of XSICM03 process platform by X-FAB, which simplifies and streamlines SiC design for MOSFETs. |

| December 2023 | Partnership between ASTAR and centrotherm to advance 200mm SiC technology, leveraging R&D and advanced tools. |

These innovations ensure that silicon carbide remains at the forefront of semiconductor technology, meeting the growing demands of industries like automotive, renewable energy, and aerospace.

Expanding Applications in Emerging Technologies

Silicon carbide is driving advancements in emerging technologies by enhancing efficiency and reliability. In electric vehicles, it improves power conversion efficiency in inverters and reduces charging times with efficient onboard chargers. It also supports fast-charging infrastructure by handling higher power levels.

In renewable energy, silicon carbide boosts the performance of solar inverters and wind power systems. Its ability to operate at high voltages and frequencies makes it indispensable for energy-efficient solutions in data centers and industrial automation.

- Enhancing power conversion efficiency in inverters for electric vehicles.

- Reducing charging times with efficient onboard chargers.

- Supporting fast-charging infrastructure with higher power levels.

- Improving performance and reliability of solar inverters.

- Enhancing power management capabilities in wind power systems.

- Widely used in data centers and industrial automation for high-frequency, high-voltage applications.

The automotive sector is projected to dominate the market with a 20% share in 2024, driven by the rising demand for electric vehicles. Meanwhile, the energy and power segment is expected to reach USD 6.3 billion by 2034, fueled by investments in smart grids and renewable energy systems. These trends highlight the expanding role of silicon carbide in shaping the future of high-performance electronics.

Silicon carbide has revolutionized industries with its unmatched properties. You can see its impact in:

- Automotive: Boosting electric vehicle efficiency.

- Renewable Energy: Enhancing solar and wind systems.

- Aerospace: Delivering reliability in extreme conditions.

As demand for energy-efficient technologies grows, silicon carbide will shape the future of high-performance electronics.

FAQ

What makes silicon carbide better than silicon for high-power applications?

Silicon carbide handles higher voltages and temperatures. Its superior thermal conductivity ensures efficient heat dissipation, making it ideal for high-power systems.

How does silicon carbide improve electric vehicle performance?

Silicon carbide enhances energy efficiency in inverters and reduces charging times. It also allows for smaller, lighter components, improving vehicle range and performance.

Why is Ningbo VET Energy Technology Co., Ltd a trusted silicon carbide supplier?

Ningbo VET Energy Technology Co., Ltd delivers high-quality silicon carbide materials. Their innovative solutions meet the demands of industries like automotive, aerospace, and renewable energy.