Graphite plates play a critical role in hydrogen fuel cells, driving sustainable energy solutions. A graphite plate for chemical applications ensures high conductivity and resistance to corrosion. Its use as a graphite plate for electrolysis or as a graphite plate for electrode enhances performance and efficiency. Durable graphite anode plates also reduce emissions, supporting eco-friendly manufacturing practices.

Wichtigste Erkenntnisse

- Graphite plates help hydrogen fuel cells work better. They carry electricity well, giving more power and wasting less energy.

- Graphite plates last a long time, so they don’t need to be replaced often. This cuts down on trash and helps the environment.

- Using graphite plates in fuel cells lowers carbon pollution. They are important for switching to cleaner energy.

Hydrogen Fuel Cells and Clean Energy

What Are Hydrogen Fuel Cells?

Hydrogen fuel cells are advanced energy systems that generate electricity through an electrochemical reaction. Instead of burning fuel, they combine hydrogen and oxygen to produce power, emitting only water vapor and heat as byproducts. This process makes them a clean and efficient alternative to traditional combustion engines.

Hydrogen can be sourced from various domestic resources, including natural gas, biomass, and renewable energy through electrolysis. These methods have the potential to achieve near-zero greenhouse gas emissions. Additionally, hydrogen fuel cells boast an impressive energy efficiency of approximately 60%, converting more than half of the hydrogen’s energy into usable electricity. When paired with combined heat and power (CHP) systems, their efficiency can reach up to 85%.

The Role of Hydrogen Fuel Cells in Reducing Emissions

Hydrogen fuel cells play a pivotal role in reducing global carbon emissions. By transitioning from fossil fuels to hydrogen-based energy, industries and transportation sectors can significantly lower their environmental impact. For instance, clean hydrogen production through electrolysis could save up to 1.2 gigatons of CO2 annually, equivalent to the emissions from 285 million gasoline-powered cars.

Vor kurzem advancements in hydrogen technology further enhance its potential. Innovations in hydrogen storage systems and automated refueling stations improve accessibility and convenience. Fuel cell electric vehicles (FCEVs) now offer extended ranges and faster refueling times, making them a viable alternative to traditional vehicles. Globally, the number of hydrogen refueling stations has surpassed 3,000, with rapid growth in regions like South Korea and California.

By integrating hydrogen fuel cells into energy systems, societies can move closer to achieving a low-carbon future while fostering sustainable development.

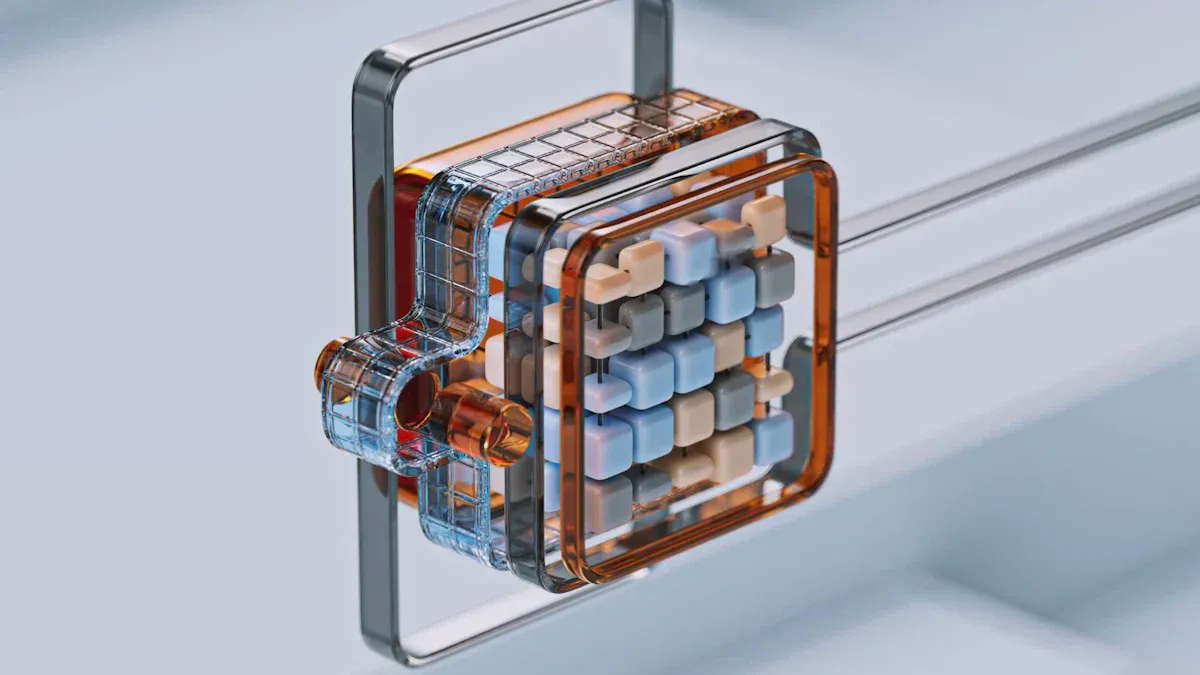

The Importance of Graphite Plates

How Graphite Plates Enhance Fuel Cell Efficiency

Graphite plates significantly improve the efficiency of hydrogen fuel cells by optimizing the electrochemical reactions within the system. Their high electrical conductivity ensures seamless electron transfer, which maximizes power output. This property reduces energy losses, making the fuel cell more efficient in converting hydrogen into electricity. Additionally, the lightweight nature of graphite plates minimizes the overall weight of the fuel cell, enhancing its performance in applications like transportation.

Recent studies highlight the role of advanced materials in improving fuel cell efficiency. For example, researchers have explored various composites to enhance electrode performance. The table below summarizes findings from notable experiments:

| Studie | Material verwendet | Enhancement Description |

|---|---|---|

| Zhao et al. | MnO2/polypyrrole carbon cloth | Improved microbial fuel cell (MFC) performance |

| Dessie et al. | α-MnO2/polyaniline nanocomposite | Enhanced pencil graphite electrodes for power generation |

| Sarma et al. | PPy-co-PANI/Fe3O4-modified carbon paper | Dye degradation and power generation in MFCs |

These findings underscore the potential of graphite-based materials in advancing fuel cell technology. By integrating graphite plates, manufacturers can achieve higher energy efficiency and contribute to sustainable energy solutions.

Durability and Longevity of Graphite Plates

Graphite plates offer exceptional durability, making them a reliable choice for hydrogen fuel cells. Their chemical stability protects the fuel cell components from corrosion, even in harsh operating conditions. This resistance to chemical degradation ensures consistent performance over extended periods, reducing the need for frequent maintenance.

The mechanical strength of graphite plates provides structural integrity, preventing deformation or damage during operation. Furthermore, their thermal resistance effectively dissipates heat, safeguarding the fuel cell from overheating. These properties collectively enhance the operational lifespan of hydrogen fuel cells. The table below outlines the key attributes of graphite plates that contribute to their durability:

| Eigentum | Beschreibung |

|---|---|

| Hohe elektrische Leitfähigkeit | Facilitates efficient electron transfer, optimizing power output. |

| Chemische Stabilität | Shields components from corrosion, ensuring long-term durability. |

| Mechanische Kraft | Prevents deformation, maintaining consistent performance over time. |

| Wärmebeständigkeit | Dissipates heat, prolonging the operational lifespan of fuel cells. |

By incorporating graphite plates, manufacturers can produce fuel cells that require minimal upkeep while delivering reliable performance.

Vergleich mit alternativen Materialien

Graphite plates outperform alternative materials like metal and polymer composites in several key areas. Unlike metals, graphite does not corrode, even when exposed to the humid and acidic environment inside a fuel cell. This advantage eliminates the need for protective coatings, which can add complexity and cost to the manufacturing process.

In comparison to polymer composites, graphite plates offer superior electrical conductivity and thermal resistance. While polymers may provide lightweight solutions, they often lack the durability and efficiency required for long-term fuel cell applications. Graphite plates strike a balance between weight, performance, and longevity, making them the preferred choice for sustainable manufacturing.

The adoption of graphite plates in hydrogen fuel cells represents a significant step toward reducing carbon footprints. Their unique properties not only enhance fuel cell efficiency but also ensure durability and reliability, supporting the transition to cleaner energy systems.

Environmental and Manufacturing Benefits

Reducing Carbon Footprints with Graphite Plates

Graphite plates contribute significantly to reducing carbon footprints in hydrogen fuel cells. Their high electrical conductivity minimizes energy losses during the electrochemical reaction, ensuring efficient energy conversion. This efficiency reduces the overall energy demand, which, in turn, lowers greenhouse gas emissions. Additionally, graphite plates do not corrode or degrade easily, eliminating the need for frequent replacements. This durability reduces waste and the environmental impact associated with manufacturing new components.

The lightweight nature of graphite plates also plays a role in reducing emissions. In transportation applications, lighter fuel cells improve vehicle efficiency, leading to lower fuel consumption and reduced CO2 emissions. By integrating graphite plates into hydrogen fuel cells, industries can adopt cleaner energy systems while minimizing their environmental impact.

Sustainable Manufacturing of Graphite Plates

The production of graphite plates has evolved to prioritize sustainability. Recent advancements focus on environmentally friendly processes that reduce the reliance on traditional materials like coal and petroleum. For instance, a low-temperature production method eliminates the need for polymer binders, significantly reducing environmental impact and production time. This approach not only supports cleaner manufacturing but also lowers costs, making fuel cell technology more accessible.

Studies emphasize the importance of harmonized frameworks to evaluate the environmental impacts of graphite-based materials. These assessments identify key areas for improvement, such as reducing energy consumption during production and utilizing renewable energy sources. Prospective models predict that future advancements in electricity production will further decrease the environmental footprint of graphitplatte manufacturing. By adopting these sustainable practices, manufacturers can align with global efforts to combat climate change.

Key metrics validating the sustainability of graphite plate production include:

- The use of lab-scale data to analyze variations in environmental impacts.

- Implementation of processes with lower environmental footprints.

- Reduction of uncertainty in production impacts through advanced modeling.

- Elimination of coal and petroleum in production methods.

These innovations highlight the commitment of manufacturers to producing graphite plates in an eco-friendly manner.

Contribution to a Low-Carbon Future

Graphite plates are poised to play a pivotal role in the transition to a low-carbon future. The global demand for graphite is projected to quadruple by 2030, driven by its critical applications in clean energy technologies. Hydrogen fuel cells, electric vehicle batteries, and renewable energy storage systems all rely heavily on graphite for their efficiency and performance.

The expansion of renewable energy projects further underscores the importance of graphite. Energy storage systems, essential for stabilizing renewable energy grids, depend on graphite’s high energy density and thermal stability. Additionally, graphite’s role in high-heat applications supports industries like steel and aluminum, which are integral to building sustainable infrastructure.

The graphite market is expected to grow from USD 15.67 billion in 2024 to USD 36.40 billion by 2030, reflecting its increasing importance in global sustainability efforts. By integrating graphite plates into hydrogen fuel cells and other clean energy systems, industries can accelerate the shift toward a greener, more sustainable future.

Graphite plates are essential for advancing hydrogen fuel cell technology and promoting sustainability. Their unique properties enhance efficiency, durability, and environmental performance. Recent studies highlight that electric vehicles powered by clean energy can reduce lifecycle emissions by 50%, with an additional 25% reduction possible through low-carbon electricity. These advancements underscore graphite plates’ pivotal role in achieving a greener future.

FAQ

What makes a graphite plate ideal for hydrogen fuel cells?

Its high electrical conductivity, chemical stability, and lightweight nature make it an efficient and durable choice for optimizing hydrogen fuel cell performance.

How does a graphite plate contribute to sustainability?

It reduces energy losses, minimizes waste through durability, and supports eco-friendly manufacturing processes, aligning with global efforts to lower carbon footprints.

Can graphite plates be recycled?

Yes, they can be recycled. Manufacturers often implement processes to recover and reuse graphite materials, further enhancing their sustainability and reducing environmental impact.