Sélection de la droite graphite susceptor coating is essential for high-temperature applications. Graphite Susceptor Coating options like Revêtement TaC provide outstanding thermal stability, while TiC-TaC hybrid coatings improve wear resistance with optimized TiC content, such as 8.0 wt%, enhancing performance across a temperature range of 25 °C to 800 °C. Additionally, innovations such as DCV Revêtement TaC et SIC Coating deliver cost-effectiveness by lowering production expenses and boosting reliability in challenging environments, including semiconductor manufacturing and renewable energy industries. The use of advanced CVD SIC Coating further ensures durability and efficiency, making it a preferred choice for critical applications.

Traits clés

- TaC coatings handle heat very well. They work great for very high-temperature uses like in space or nuclear reactors.

- TiC-TaC hybrid coatings are strong and resist wear. They are good for jobs with heavy use and rough conditions.

- Choisir les best coating depends on heat, stress, chemicals, cost, and how long it needs to last.

Overview of Graphite Susceptor Coatings

What Are Graphite Susceptors?

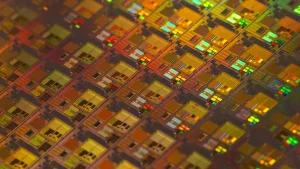

Graphite susceptors are specialized components used in high-temperature applications. These materials, made from graphite, serve as intermediaries for heat transfer in processes such as chemical vapor deposition (CVD) and semiconductor manufacturing. Their ability to withstand extreme temperatures makes them indispensable in industries requiring precise thermal control.

Graphite’s unique properties, including high thermal conductivity and chemical stability, enable it to perform effectively in demanding environments. However, its inherent porosity and susceptibility to oxidation at elevated temperatures necessitate additional protection to maintain performance and longevity.

Why Are Coatings Necessary?

Coatings play a critical role in enhancing the functionality of graphite susceptors. Without protective layers, graphite can degrade rapidly due to oxidation, chemical reactions, or mechanical wear. Coatings like tantalum carbide (TaC) and titanium carbide-tantalum carbide (TiC-TaC) hybrids provide a barrier against these challenges, ensuring the susceptor remains durable and efficient.

- Oxidation Resistance: Coatings prevent graphite from reacting with oxygen, especially in high-temperature environments.

- Improved Wear Resistance: Protective layers reduce surface erosion caused by friction or abrasive forces.

- Durée de vie prolongée: Coatings minimize degradation, allowing graphite susceptors to perform reliably over extended periods.

The choice of coating depends on the specific application requirements, including temperature range, chemical exposure, and cost considerations. Selecting the right Graphite Susceptor Coating ensures optimal performance and cost-effectiveness in critical industrial processes.

Revêtements TaC

Propriétés des clés

Tantalum carbide (TaC) coatings exhibit a unique combination of physical and chemical properties, making them highly suitable for demanding industrial applications. These properties include exceptional thermal stability, high hardness, and excellent chemical resistance. The following table summarizes the key characteristics of TaC coatings:

| Biens | Désignation des marchandises |

|---|---|

| Conductivité électrique | TaC exhibits metallic electrical conductivity with temperature dependence. |

| Superconductivity | TaC is a superconductor with a transition temperature of 10.35 K. |

| Magnetic Properties | Changes from diamagnetic for x ≤ 0.9 to paramagnetic at larger x. |

| Point de fusion | TaC has a high melting point, making it suitable for ultra-high temperature applications. |

| Dureté | Known for its exceptional hardness, contributing to its use in aerospace applications. |

| Module élastique | Exhibits a high elastic modulus, enhancing its mechanical performance. |

| Conductivité thermique | Good thermal conductivity, important for thermal management in high-performance applications. |

| Résistance aux chocs thermiques | Excellent resistance to thermal shock, beneficial for materials exposed to rapid temperature changes. |

| Stabilité chimique | High chemical stability, making it suitable for harsh environments in aerospace and industrial uses. |

| Toux de fracture | Improved fracture toughness when used as a reinforcement in composites, enhancing durability. |

| Grain Size Influence | Smaller grain sizes lead to improved yield stress due to Hall-Petch relationship. |

These properties enable TaC coatings to perform reliably in extreme conditions, such as high-temperature environments and chemically aggressive settings.

Avantages

TaC coatings offer several advantages that make them a preferred choice for various industries:

- Stabilité thermique: The high melting point of TaC ensures stability in ultra-high temperature applications, such as aerospace and nuclear reactors.

- Résistance au port: Exceptional hardness provides superior resistance to abrasion and mechanical wear, extending the lifespan of coated components.

- Résistance chimique: TaC’s chemical stability protects against corrosion and oxidation, even in harsh environments.

- Conductivité thermique: Efficient heat transfer capabilities make it ideal for applications requiring precise thermal management.

- Durabilité: Enhanced fracture toughness and elastic modulus contribute to the long-term reliability of TaC-coated materials.

These advantages align with the needs of industries that demand robust and reliable solutions for high-performance applications.

Désavantages

Despite its numerous benefits, TaC coatings have certain limitations:

- Coût: The production of TaC coatings involves complex processes, leading to higher costs compared to other coating materials.

- Faiblesse: While TaC exhibits excellent hardness, its brittleness can pose challenges in applications requiring high impact resistance.

- Processing Challenges: Achieving uniform and defect-free TaC coatings requires advanced techniques, which may increase manufacturing complexity.

Understanding these drawbacks is essential for determining whether TaC coatings are the right choice for a specific application.

Demandes

Revêtements TaC find applications across a wide range of industries due to their unique properties:

- Aéronautique: Used in turbine blades and rocket nozzles for their ability to withstand extreme temperatures and mechanical stress.

- Fabrication de semi-conducteurs: Protects graphite susceptors in chemical vapor deposition (CVD) processes, ensuring durability and efficiency.

- Nuclear Industry: Serves as a protective layer in nuclear reactors, where high thermal stability and chemical resistance are critical.

- Industrial Tools: Enhances the performance and lifespan of cutting tools and wear-resistant components.

The versatility of TaC coatings makes them a valuable solution for industries requiring high-performance materials.

TiC-TaC Hybrid Coatings

Propriétés des clés

TiC-TaC hybrid coatings combine the unique characteristics of titanium carbide (TiC) and tantalum carbide (TaC) to deliver enhanced performance in demanding industrial applications. These coatings exhibit a balance of thermal stability, mechanical strength, and chemical resistance. The inclusion of TiC improves the coating’s toughness and wear resistance, while TaC contributes to its high-temperature stability and oxidation resistance.

| Biens | Désignation des marchandises |

|---|---|

| Stabilité thermique | Maintains structural integrity at temperatures exceeding 2,000 K. |

| Résistance au port | Enhanced by the addition of TiC, reducing surface degradation in abrasive environments. |

| Oxidation Resistance | Provides a robust barrier against oxidation, even in extreme conditions. |

| Résistance mécanique | Combines the hardness of TaC with the toughness of TiC for superior durability. |

| Chemical Compatibility | Resistant to corrosive chemicals, making it suitable for harsh industrial processes. |

These properties make TiC-TaC hybrid coatings a versatile solution for applications requiring both durability and high-temperature performance.

Avantages

TiC-TaC hybrid coatings offer several advantages over traditional single-component coatings:

- Enhanced Ablation Resistance: The hybrid composition significantly improves resistance to material loss in high-temperature environments.

- Improved Toughness: The addition of TiC reduces brittleness, making the coating more resilient under mechanical stress.

- Durée de vie prolongée: Superior wear and oxidation resistance ensure longer operational life for coated components.

- Cost Efficiency: The optimized combination of TiC and TaC reduces material costs while maintaining high performance.

Research highlights the effectiveness of these coatings in extreme environments. For example, studies on C/C composites with 14 vol% TaC content demonstrated exceptional ablation resistance at temperatures exceeding 2,000 K for 120 seconds. This performance underscores the potential of TiC-TaC hybrid coatings in applications such as solid rocket motors and other high-temperature systems.

Drawbacks

Despite their numerous benefits, TiC-TaC hybrid coatings have some limitations:

- Complex Manufacturing Process: Producing a uniform hybrid coating requires advanced techniques, increasing production complexity.

- Cost of Raw Materials: While more cost-effective than pure TaC coatings, the hybrid still involves expensive raw materials.

- Limited Impact Resistance: Although tougher than TaC, the hybrid coating may not withstand high-impact forces in certain applications.

Understanding these drawbacks is essential for determining the suitability of TiC-TaC hybrid coatings for specific industrial needs.

Demandes

TiC-TaC hybrid coatings are widely used across various industries due to their unique properties:

- Aéronautique: Protects components like turbine blades and rocket nozzles from extreme heat and mechanical stress.

- Fabrication de semi-conducteurs: Enhances the durability of graphite susceptors in chemical vapor deposition (CVD) processes.

- Energy Sector: Improves the performance of components in renewable energy systems, such as solar panels and fuel cells.

- Industrial Tools: Extends the lifespan of cutting tools and wear-resistant parts in manufacturing processes.

The versatility and reliability of TiC-TaC hybrid coatings make them a preferred choice for industries requiring high-performance materials.

Direct Comparison of TaC and TiC-TaC Hybrid Coatings

Performance dans les environnements à haute température

TaC coatings excel in ultra-high-temperature environments due to their exceptional thermal stability and high melting point. These properties make them ideal for applications like aerospace and nuclear reactors. TiC-TaC hybrid coatings, while also capable of withstanding high temperatures, offer slightly reduced thermal stability compared to pure TaC. However, the hybrid composition compensates with improved oxidation resistance, making it suitable for prolonged exposure to extreme conditions.

For industries requiring consistent performance at temperatures exceeding 2,000 K, both coatings provide reliable solutions, but the choice depends on the specific thermal demands of the application.

Durabilité et résistance au port

TiC-TaC hybrid coatings outperform TaC in terms of wear resistance. The addition of titanium carbide enhances toughness and reduces brittleness, allowing the hybrid coating to endure mechanical stress more effectively. TaC coatings, while harder, are more prone to cracking under impact. This distinction makes the hybrid coating a better choice for applications involving abrasive forces or frequent mechanical contact.

Rentabilité

TaC coatings are more expensive due to the complexity of their production and the cost of raw materials. TiC-TaC hybrid coatings, by incorporating titanium carbide, reduce material costs while maintaining high performance. This cost advantage makes the hybrid coating a more economical option for industries with budget constraints.

Applicabilité

The choice between TaC and TiC-TaC hybrid coatings depends on the application. TaC coatings are preferred for ultra-high-temperature environments and chemically aggressive settings. TiC-TaC hybrid coatings, with their enhanced toughness and cost efficiency, are better suited for applications requiring durability and moderate thermal stability. Industries must evaluate their specific needs to select the most appropriate Graphite Susceptor Coating.

Choosing the Right Graphite Susceptor Coating

Facteurs à considérer

Selecting the appropriate coating for suscepteurs de graphite requires careful evaluation of several factors. Each application has unique demands, and understanding these requirements ensures optimal performance and cost-efficiency. Below are the key considerations:

-

Température de fonctionnement: The thermal stability of the coating must align with the application’s temperature range. TaC coatings excel in ultra-high-temperature environments, while TiC-TaC hybrids offer reliable performance in moderately high temperatures with added oxidation resistance.

-

Mechanical Stress: Applications involving frequent mechanical contact or abrasive forces benefit from coatings with enhanced toughness. TiC-TaC hybrid coatings, with their improved wear resistance, are better suited for such conditions.

-

Chemical Exposure: Industries dealing with corrosive chemicals or reactive environments require coatings with superior chemical resistance. TaC coatings provide excellent protection in such scenarios.

-

Budget Constraints: Cost considerations often influence the choice of coating. TiC-TaC hybrid coatings offer a more economical solution without compromising durability, making them ideal for budget-sensitive projects.

-

Application Longevity: The expected lifespan of the coated component plays a crucial role. Coatings with higher wear resistance and oxidation protection, such as TiC-TaC hybrids, ensure extended operational life.

Conseil: Conducting a thorough analysis of the operational environment and performance requirements helps in making an informed decision.

TaC coatings excel in ultra-high-temperature environments, while TiC-TaC hybrids offer enhanced toughness and cost efficiency. Selecting the right coating depends on operational demands, such as temperature, wear resistance, and budget.

Recommendation: Industries should evaluate specific application needs to choose coatings that balance performance, durability, and cost-effectiveness.

FAQ

What is the primary difference between TaC and TiC-TaC hybrid coatings?

TaC coatings excel in ultra-high-temperature stability, while TiC-TaC hybrids offer enhanced toughness and cost efficiency, making them suitable for moderate thermal and abrasive conditions.

How do TiC-TaC hybrid coatings improve wear resistance?

The addition of titanium carbide increases toughness, reducing brittleness and enhancing the coating’s ability to withstand mechanical stress and abrasive forces in industrial applications.

Are TiC-TaC hybrid coatings more cost-effective than TaC coatings?

Yes, TiC-TaC hybrids reduce material costs by combining titanium carbide with tantalum carbide, offering a balance of performance and affordability for budget-sensitive industries.

Conseil: Evaluate the specific operational environment to determine the most cost-effective and durable coating solution.