SiC solide CVD de haute pureté en vrac offre une percée dans la production de semi-conducteurs. Vous pouvez compter sur sa conductivité thermique inégalée pour gérer efficacement la chaleur. Sa durabilité assure la stabilité dans des conditions extrêmes. En outre, les applications avancées comme revêtement cvd tac et enduits de tac profiter de sa précision, en faisant une pierre angulaire des technologies modernes de semi-conducteurs.

Traits clés

- SiC solide CVD de haute pureté en vrac se déplace très bien la chaleur, en maintenant les dispositifs semi-conducteurs au frais. 1

- Sa force et sa résistance aux produits chimiques le rendent fiable, même dans des conditions difficiles, donc il dure plus longtemps.

- Ce matériel améliore la précision et facilite la production, parfait pour les nouvelles technologies et les machines puissantes.

Comprendre la haute pureté CVD En vrac solide SiC

Propriétés et caractéristiques uniques

SiC solide CVD de haute pureté en vrac se distingue par ses propriétés exceptionnelles. Vous constaterez qu'il offre une conductivité thermique remarquable, qui est cruciale pour la gestion de la chaleur dans les dispositifs semi-conducteurs. Ce matériau possède également une grande résistance mécanique, ce qui le rend résistant à l'usure. Sa stabilité chimique garantit qu'elle reste intacte par les environnements difficiles. Ces caractéristiques en font un choix idéal pour les applications de haute technologie.

Le rôle de la pureté dans les applications des semi-conducteurs

La pureté joue un rôle vital dans les applications des semi-conducteurs. Lorsque vous utilisez High Pureity CVD Solid SiC Bulk, vous assurez que vos dispositifs semi-conducteurs fonctionnent au mieux. Les impuretés peuvent entraîner des défauts et réduire l'efficacité des composants électroniques. En maintenant des niveaux de pureté élevés, vous minimisez ces risques. Il en résulte des dispositifs plus fiables et plus efficaces, qui sont essentiels pour les technologies de pointe.

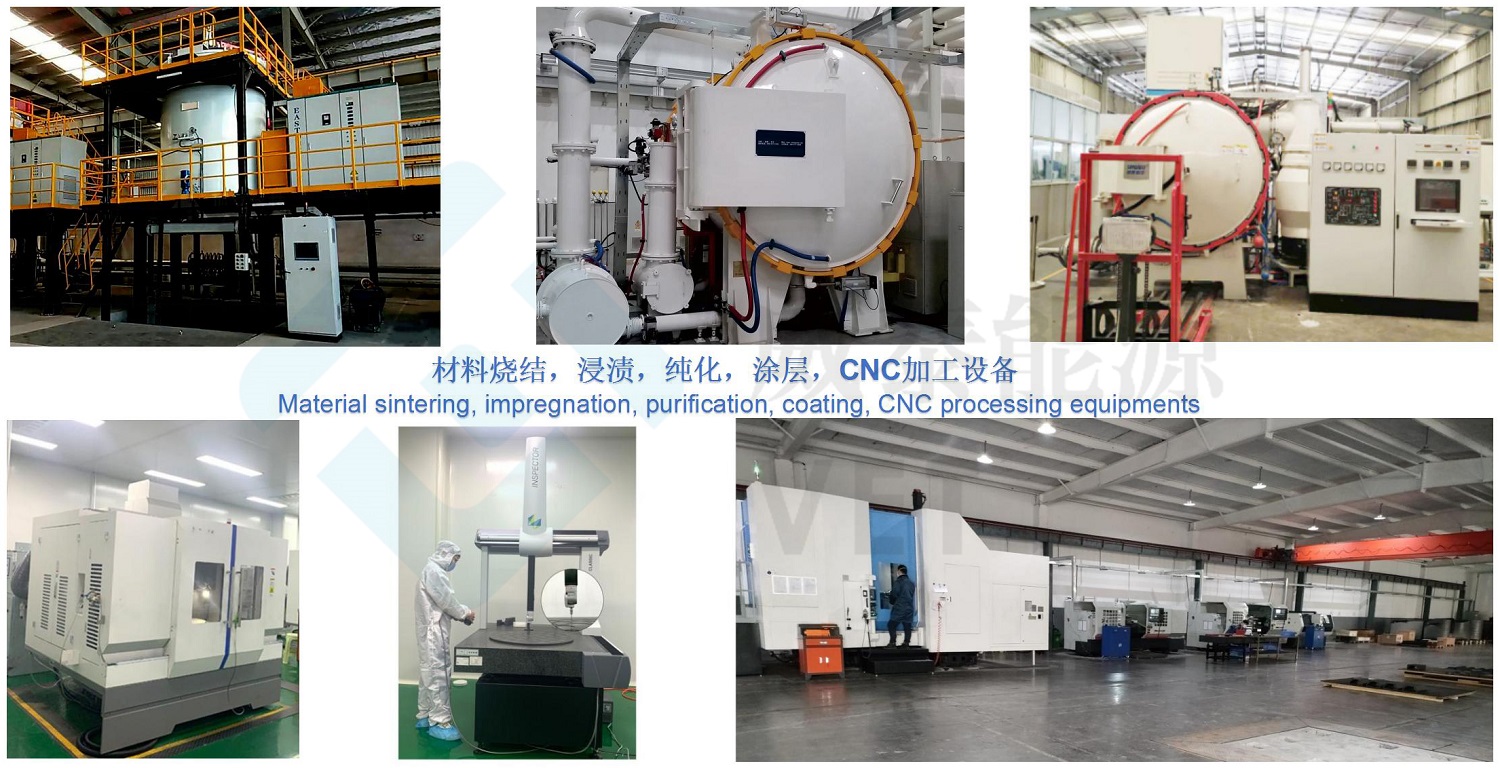

Comment l'énergie de la FEP produit une forte pureté CVD solide en vrac SiC

FEP L'énergie utilise un processus méticuleux pour produire du solide SiC Bulk à haute pureté CVD. Vous apprécierez l'utilisation de la méthode de dépôt de vapeur chimique (CVD), qui assure une pureté et une densité ultra-hautes. Le processus commence par la préparation d'une source de bloc CVD-SiC de haute qualité. Cette source subit une sublimation dans un environnement contrôlé, passant du solide à la vapeur. Il se condense ensuite sur un substrat, formant des cristaux simples SiC de haute qualité. FEP La gestion précise de la température et l'utilisation de gaz inertes empêchent la contamination, assurant l'intégrité des cristaux.

Avantages de la haute pureté CVD En vrac solide SiC dans la fabrication de semi-conducteurs

Conductivité thermique accrue pour la gestion de la chaleur

Vous savez que gérer la chaleur est essentiel dans les dispositifs semi-conducteurs. SiC solide CVD de haute pureté en vrac offre une conductivité thermique exceptionnelle, vous permettant de dissiper efficacement la chaleur. Cette propriété garantit que vos appareils fonctionnent à des températures optimales, même sous de lourdes charges de travail. En utilisant ce matériau, vous réduisez le risque de surchauffe, ce qui peut endommager les composants et réduire les performances. Sa capacité à gérer des charges thermiques élevées le rend idéal pour les appareils électroniques de haute puissance et les applications de semi-conducteurs avancées.

Durabilité et stabilité dans des conditions extrêmes

Lorsque vous travaillez avec des matériaux semi-conducteurs, la durabilité est essentielle. DCV haute pureté SiC solide Bulk fournit une résistance mécanique exceptionnelle et la stabilité chimique. Il résiste à l'usure, même dans des environnements difficiles. Ce matériau fonctionne de façon fiable sous des températures et des pressions extrêmes, assurant une stabilité à long terme. Vous pouvez lui faire confiance pour maintenir son intégrité dans des applications exigeantes, comme l'aérospatiale, l'automobile et l'électronique industrielle. Sa résilience réduit le besoin de remplacements fréquents, ce qui vous permet d'économiser du temps et des ressources.

Précision et scalabilité pour les technologies avancées

La précision est essentielle dans la fabrication moderne de semi-conducteurs. DCV haute pureté SiC solide Bulk vous permet d'atteindre des niveaux élevés de précision pendant la production. Son uniformité et sa consistance soutiennent la croissance de cristaux simples SiC de haute qualité. Cette précision garantit que vos appareils répondent à des normes de performance strictes. En outre, l'évolutivité du matériau vous permet de produire des composants pour une large gamme d'applications, des petits capteurs aux grands modules de puissance. Sa polyvalence en fait un atout précieux pour faire progresser la technologie.

Comparaison de la haute pureté CVD Solid SiC Bulk avec des matériaux traditionnels

Avantages sur le silicone

Lorsque vous comparez le silicium avec le solide SiC Bulk de haute pureté CVD, les différences deviennent claires. Silicone lutte pour gérer les températures élevées et les niveaux de puissance. Sa conductivité thermique est plus faible, ce qui la rend moins efficace pour dissiper la chaleur. Cette limitation peut entraîner une surchauffe et une réduction des performances dans les applications de haute puissance. D'autre part, le carbure de silicium offre une conductivité thermique supérieure, vous permettant de gérer la chaleur plus efficacement. Cela le rend idéal pour les appareils qui fonctionnent sous de lourdes charges de travail.

Le silicone manque également de la force mécanique nécessaire pour des conditions extrêmes. Il peut craquer ou se dégrader lorsqu'il est exposé à un stress élevé ou à des environnements difficiles. DCV haute pureté SiC solide Bulk fournit la durabilité dont vous avez besoin pour une fiabilité à long terme. Sa stabilité chimique assure une performance constante, même dans des situations difficiles. Ces avantages en font un meilleur choix pour les technologies de semi-conducteurs de pointe.

Avantages sur les composites de carbure de silicone

Les composites de carbure de silicium offrent quelques avantages, mais ils sont insuffisants dans des domaines clés. Les composés contiennent souvent des impuretés qui peuvent affecter la qualité du produit final. Vous pouvez constater que ces impuretés entraînent des incohérences dans la performance. DCV haute pureté SiC solide Bulk élimine ce problème en maintenant une pureté ultra élevée. Cela garantit une efficacité et une fiabilité optimales de vos appareils.

Les composites manquent également de l'uniformité requise pour les applications de précision. Leur structure peut varier, rendant plus difficile l'obtention de résultats cohérents. DCV haute pureté SiC solide Bulk fournit un matériau uniforme et dense, qui soutient la croissance de cristaux uniques de haute qualité. Cette précision est essentielle pour les technologies de pointe comme l'électronique de haute puissance et les capteurs. En choisissant ce matériau, vous gagnez un avantage concurrentiel dans la fabrication de semi-conducteurs.

DCV haute pureté SiC solide Production de semi-conducteurs en vrac. Vous gagnez une conductivité thermique inégalée, la durabilité et la précision pour des applications avancées. Ce matériau vous aide à atteindre une efficacité et une fiabilité plus élevées. Au fur et à mesure que la technologie progresse, elle vous assure de rester compétitif dans la fabrication. Explorez son potentiel pour élever vos projets et répondre aux demandes futures.

FAQ

Ce qui rend la haute pureté CVD Solid SiC Bulk unique?

DCV haute pureté SiC solide Bulk offres inégalées conductivité thermique, durabilité et stabilité chimique. Sa pureté ultra-haute assure une performance constante dans les applications de semi-conducteurs avancées.

Comment ce matériau améliore-t-il la fabrication de semi-conducteurs?

Vous obtenez une meilleure gestion de la chaleur, la précision et l'évolutivité avec ce matériau. Ses propriétés améliorent la fiabilité et l'efficacité de l'appareil, en particulier dans les applications à haute puissance et les conditions extrêmes.

Peut haute pureté CVD SiC solide En vrac, remplacer les matériaux traditionnels ?

Oui, il surpasse les composites de carbure de silicium et de silicium. Sa conductivité thermique supérieure, sa durabilité et sa pureté en font un meilleur choix pour les technologies de pointe.