タックコーティング市場の概要

現在の市場規模と成長率

タックコーティング市場は、近年安定した成長を遂げています。 高性能材料を必要とする産業の採用の増加にこの拡張を分析します。 世界的な市場規模は、2025年までに期待を超える化合物の年間成長率(CAGR)を示す投影で重要なマイルストーンに達しました。 この上向きの軌跡は耐久性および熱抵抗を高める高度のコーティングの解決のための成長する要求を反映します.

タックコーティングの主な用途

タックコーティングは、複数の業界において幅広い用途に対応しています。 半導体分野では、これらのコーティングは、極端な温度や摩耗から部品を保護します。 航空宇宙メーカーは、タービンブレードなどの重要な部品の性能を向上させるために、TACコーティングに依存しています。 これらのコーティングによって提供される高められた寿命および効率からの産業機械類の利点。 また、エネルギー・発電分野は、過酷な操業条件に耐えるために、TACコーティングを利用しています.

高機能産業におけるTACコーティングの役割

高性能の業界は、厳格な運用要件を満たすTaCコーティングに依存します。 これらのコーティングは、厳しい環境で欠くことのできない硬度、熱安定性、耐薬品性を提供します。 コンポーネントの寿命を延ばし、メンテナンスコストを削減することにより、TACコーティングは運用効率に貢献します。 イノベーションと持続可能性のさらなる役割は、現代の産業用途における重要性を強調しています.

主なトレンド タックコーティングマーケットの形成

コーティングプロセスにおける技術開発

タックコーティング市場は、コーティング技術の大きな進歩を目撃しました。 メーカーは、プラズマ強化化学蒸着(PECVD)や原子層蒸着(ALD)などの高度な方法を採用し、精密で均一なコーティングを実現します。 これらの技術は付着を改善し、欠陥を減らすことによってTACのコーティングの性能を高めます。 コーティングプロセスのオートメーションはまた高いスループットおよび一貫した質を可能にする生産を合理化しました。 これらの進歩は高性能材料を要求する企業のためにより信頼できる TaC のコーティングをしました.

サステナビリティと環境に優しいコーティングソリューション

サステナビリティは、TACコーティング業界にとって重要な焦点となっています。 企業は環境影響を減らすために環境に優しいコーティングの解決を開発しています。 水性と無溶剤の処方は、従来の方法の代替としてトラクションを獲得しています。 また、炭素排出量を最小限にするために、エネルギー効率の高いコーティングプロセスを採用しています。 これらの取り組みは、地球環境に配慮したステークホルダーに対して、グローバルな持続可能性の目標と魅力を合わせています.

Rising Demand in Emerging Markets

アジア・パシフィック、中南米の新興市場は、TACコーティングの需要を担っています。 これらの地域の急速な産業化およびインフラ開発は高性能材料の必要性を高めました。 航空宇宙、半導体、エネルギーなどの産業が事業を拡大し、TACコーティングメーカーの機会を創出しています。 地方自治体は、先進的な製造技術に投資し、市場成長をさらに高めています.

物質科学とナノテクノロジーのイノベーション

マテリアルサイエンスとナノテクノロジーは、TACコーティング市場を変革しています。 ナノ構造のTACコーティングを研究し、硬度、耐熱性、耐摩耗性などの特性を強化しています。 これらの革新は薄くけれどより耐久のコーティングの開発を可能にしま、材料の使用法および費用を削減します。 新しいアプリケーションをアンロックし、市場の潜在能力を拡大するなど、このような画期的な製品が期待されています.

成長ドライバーと課題

成長の運転者

半導体・航空宇宙産業の需要拡大

半導体および航空宇宙産業は、引き続きTaCコーティングの需要を促進します。 半導体製造では、コーティングは、極端な温度や摩耗から重要なコンポーネントを保護し、運用効率を保証します。 エアロスペース用途は、タービンブレードの耐久性や高性能部品の耐久性を向上する能力の恩恵を受けています。 これらの業界は、過酷な条件に耐えることができる材料を優先し、TaCコーティングを重要なソリューションにします.

高温用途の拡大

エネルギー・防衛・産業分野における高温用途が急速に拡大しています。 タックコーティングは、コンポーネントが極端な熱に直面する環境に最適です。 発電設備や産業機械メーカーは、性能を向上させ、メンテナンスコストを削減するために、このコーティングを採用しています。 高温下で構造的整合性を維持できる能力は、これらの用途に適した選択肢として位置付けられます.

製造技術の進歩

製造技術の革新は、よりアクセス可能で、効率的にTaCのコーティングをしました。 化学蒸気蒸着(CVD)や物理蒸着(PVD)などの技術は、精密な用途を可能にし、材料廃棄物を削減します。 生産プロセスの自動化により、スケーラビリティと一貫性が向上し、メーカーは成長する需要を満たすことができます。 タックコーティングは、さまざまな業界に幅広く採用されています.

課題

高生産コストと材料の希少性

TaCコーティングの生産は原料抽出および処理の複雑さによる高いコストを伴います。 タンタルと炭素化合物の限られた可用性は、この課題をさらに悪化させます。 メーカーは、費用対効果の高い代替手段を開発し、これらの問題に対処するために既存のプロセスを最適化するために研究に投資する必要があります.

サプライチェーンの破壊

世界的なサプライチェーンの混乱は、TACコーティング市場にとって重要な課題を提起しています。 まれな材料および国際的な製造者による依存は遅れおよび価格の変動に企業を脆弱にします。 企業は、サプライチェーンを多様化し、これらのリスクを軽減するために現地のパートナーシップを確立しなければなりません.

規制・環境問題

厳しい環境規制は、TACコーティングの生産と適用に影響を及ぼします。 政府は、排出量を削減し、持続可能な慣行を促進するための政策を強化しています。 メーカーは、製品の品質を維持しながら、これらの規則を遵守する必要があります。 環境に優しい処方とエネルギー効率の高いプロセスを開発することで、これらの懸念に対処することができます.

市場セグメント分析

タイプ別

化学気相成長法(CVD)

化学蒸気蒸着(CVD)は、TACコーティングを適用するための広く採用された方法を表しています。 このプロセスは、薄く均一なコーティングを形成し、基質に気体前駆体の化学反応を伴います。 CVDはコーティングの厚さおよび構成上の優秀な制御を提供し、精密を要求する適用のために適したようにします。 半導体や航空宇宙などの産業は、優れた接着性で高純度のコーティングを生産する能力により、この技術に大きな利益をもたらします。 CVDのスケーラビリティは、大規模な生産をサポートし、先進材料の需要が高まっています.

物理蒸着(PVD)

物理的な蒸気の沈殿(PVD)はTaCのコーティングに使用する別の顕著な技術です。 このプロセスは、固体のソースから真空環境の基質への材料の物理的な転送を含みます。 PVDは、優れた硬度と耐摩耗性を備えたコーティングを提供し、高性能な用途に最適です。 航空機および産業機械セクターは頻繁にコンポーネントの耐久性を高めるためにPVDを利用します。 また、廃棄物を最小限に抑え、持続可能性の目標と環境への影響を削減します.

用途別

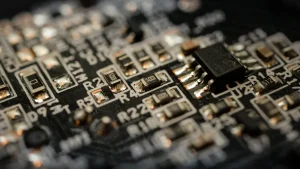

半導体業界

半導体業界は、極端な条件から部品を保護するために、TACコーティングに大きく依存しています。 これらのコーティングは、ウェーハ処理およびマイクロチップ製造で使用される機器の性能と長寿を高めます。 高温やレジストウェアに耐える能力は、この分野にとって重要な無停電生産を保証します.

航空宇宙・防衛

航空宇宙および防衛において、TACコーティングはタービンブレード、エンジンコンポーネント、およびその他の重要な部品の性能を向上させます。 酸化に対する熱安定性と抵抗は、高温環境に不可欠です。 これらの特性は、航空機および防衛システムにおけるより安全で効率的な操作に貢献します.

産業機械

タックコーティングの産業機械利点は耐久性を高め、維持の条件を減らします。 これらのコーティングは装置を摩耗および腐食から保護しま、操作寿命を拡張します。 製造や重工学などの産業は、TACコーティングを採用し、効率性を高め、ダウンタイムを削減します.

エネルギー・発電

電力と発電分野は、過酷な動作条件に耐えるために、TACコーティングを利用しています。 これらのコーティングはタービン、原子炉および他の高温システムの部品を保護します。 極端な熱の下で構造的な整合性を維持する能力は、信頼性の高い性能を確保し、運用コストを削減します.

地域的洞察と成長機会

North America

北米は、航空宇宙および半導体分野からの先進的な産業基盤および強い要求によるTACのコーティング市場で優勢なプレーヤーを残します。 米国は、研究開発の重要な投資と地域をリードします。 この地域の企業は革新を優先し、厳しい性能要件を満たすコーティング技術の改善に焦点を合わせます。 確立された製造業者および強い供給の鎖の存在は更に市場を増強します。 また、先進的な製造と防衛プロジェクトを支援する政府の取り組みでは、TACコーティングアプリケーションの成長機会を創出しています.

ヨーロッパ、中東、アフリカ(EMEA)

EMEA 地域は、航空宇宙およびエネルギー分野によって運転される TaC のコーティングの市場で安定した成長を、示します。 欧州諸国、特にドイツ、フランス、産業用途向けの高性能材料に投資 ミドルイーストは、TACコーティングが極端な条件で機器の耐久性を高めるエネルギーと発電に焦点を当てています。 アフリカは、まだ新興国ですが、その成長産業化による未適用の可能性を提示します。 地域連携と環境規制の順守は、市場のダイナミクスにも影響します.

Asia-Pacific

アジア・パシフィックは、TACコーティングの急成長を遂げる市場として、産業拡大と技術開発の進歩により燃料を供給しています。 中国、日本、韓国などの国々が半導体製造に注力し、高機能コーティングの需要が高まります。 地域の航空宇宙産業は、航空機や防衛機器の生産の増加に伴い、成長を経験しています。 インフラ整備や現地製造の政府支援により市場拡大を加速 アジア・パシフィックの費用対効果の高い生産能力は、グローバル・メーカーの拠点となります.

新興市場と未適用地域

ラテンアメリカとアフリカの新興市場は、TaCコーティング業界にとって重要な成長機会を提供します。 これらの地域の急速な都市化および産業化は耐久および有効な材料のための要求を運転します。 エネルギー、建設、輸送などの産業は、高度なコーティングを探し、作業効率を改善します。 地方自治体は、インフラやテクノロジーに投資し、市場参入に有利な環境を築きます。 これらの未適用地域は、グローバルフットプリントを拡大することを目指しているメーカーにとって有望なフロンティアを表しています.

タックコーティング市場は、技術の進歩と業界の需要増加によって駆動され、巨大な成長の可能性を示しています。 ステークホルダーは、競争を維持するために革新と戦略的な計画を優先しなければなりません。 新興市場と材料科学の画期的な市場は、市場の軌跡を形作り、変革的な成長と2025以上のアプリケーションを拡張します.