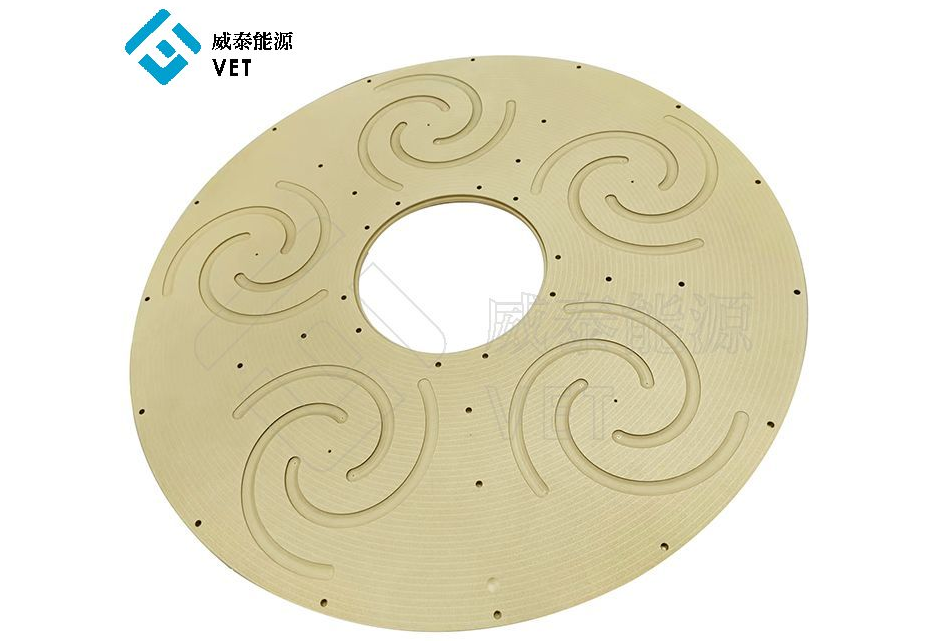

Tac coating serves as a protective layer designed to enhance the performance of critical components in semiconductor processing. It strengthens planetary receptors by shielding them from wear and tear caused by extreme conditions. This advanced coating improves manufacturing efficiency by reducing equipment failures, ensuring consistent product quality, and extending the lifespan of essential machinery.

Protective Benefits of Tac Coating

Resistance to Harsh Chemical Environments

Semiconductor processing often involves exposure to aggressive chemicals, such as etching agents and cleaning solutions. These substances can corrode or degrade unprotected surfaces over time. Tac coating provides a robust barrier that resists chemical attacks, ensuring the integrity of planetary receptors. Its non-reactive properties prevent material breakdown, even in prolonged exposure to harsh environments. This resistance reduces the risk of contamination and maintains the functionality of critical components.

Thermal Stability in High-Temperature Applications

High-temperature conditions are common in semiconductor manufacturing processes like deposition and annealing. Materials without proper protection may warp, crack, or lose efficiency under such stress. Tac coating excels in thermal stability, maintaining its structural integrity and performance at elevated temperatures. This capability ensures that planetary receptors operate reliably, even in extreme heat. By preserving their shape and functionality, the coating supports precision and consistency in manufacturing.

Durability Against Mechanical Stress

Planetary receptors endure significant mechanical stress during semiconductor processing. Repeated movements, vibrations, and impacts can lead to wear and tear. Tac coating enhances the durability of these components by providing a tough, wear-resistant surface. This added strength minimizes physical damage and extends the operational life of the equipment. As a result, manufacturers experience fewer breakdowns and improved productivity.

Tip: Investing in protective solutions like Tac coating can significantly reduce long-term maintenance costs and improve equipment reliability.

Enhancing the Lifespan of Planetary Receptors

Minimizing Maintenance and Downtime

Frequent maintenance disrupts semiconductor manufacturing processes and increases operational costs. Tac coating reduces the need for constant repairs by protecting planetary receptors from chemical, thermal, and mechanical damage. Its robust properties ensure that components remain functional for extended periods, even under demanding conditions. By minimizing wear and tear, manufacturers can schedule maintenance less frequently, leading to uninterrupted production cycles. This reduction in downtime enhances overall productivity and ensures timely delivery of high-quality products.

Cost Efficiency Through Extended Durability

Replacing damaged planetary receptors can be expensive, especially in high-volume semiconductor production. Tac coating extends the lifespan of these components, reducing the frequency of replacements. This durability translates into significant cost savings over time. Manufacturers benefit from lower expenditure on spare parts and repairs. Additionally, the enhanced longevity of coated receptors contributes to a more sustainable manufacturing process by reducing waste. Investing in Tac coating proves to be a cost-effective solution for long-term operational efficiency.

Boosting Operational Reliability

Reliable equipment is critical for maintaining precision in semiconductor processing. Tac coating enhances the structural integrity of planetary receptors, ensuring consistent performance. This reliability reduces the risk of unexpected failures that could compromise product quality or delay production schedules. By improving the dependability of key components, Tac coating supports seamless operations. Manufacturers can achieve higher yields and maintain their competitive edge in the industry. The coating’s contribution to operational stability underscores its value in advanced semiconductor manufacturing.

Role of Tac Coating in Semiconductor Manufacturing

Preventing Contamination for Higher Yields

Contamination poses a significant challenge in semiconductor manufacturing. Even microscopic particles can compromise the functionality of semiconductor devices. Tac coating acts as a protective shield, preventing contaminants from adhering to planetary receptors. Its smooth, non-porous surface minimizes particle accumulation, ensuring a cleaner production environment. By reducing contamination risks, manufacturers achieve higher yields and maintain the integrity of their products. This protective measure also supports compliance with stringent industry standards for cleanliness and quality.

Optimizing Thermal Management for Precision

Temperature control is critical in semiconductor processing. Excessive heat can distort components, leading to inaccuracies in production. Tac coating enhances thermal management by providing a stable and heat-resistant layer. This coating ensures that planetary receptors maintain consistent performance under varying thermal conditions. Its ability to dissipate heat effectively contributes to precise manufacturing processes. Improved thermal stability reduces the likelihood of defects, enabling manufacturers to produce semiconductors with exceptional accuracy.

Improving Product Quality and Consistency

Consistency is a cornerstone of semiconductor manufacturing. Variations in component performance can lead to defects and reduced product reliability. Tac coating improves the quality and uniformity of planetary receptors by enhancing their durability and resistance to environmental stressors. This consistency translates into more reliable semiconductor devices. Manufacturers benefit from fewer defects, higher customer satisfaction, and a stronger reputation in the market. The role of Tac coating in ensuring consistent product quality underscores its value in advanced manufacturing processes.

Note: Implementing Tac coating not only enhances operational efficiency but also aligns with the industry’s push for sustainable and reliable production methods.

Tac coating delivers unmatched benefits in semiconductor processing. Its protective properties enhance durability, reduce maintenance, and optimize manufacturing efficiency. By improving the lifespan of planetary receptors, it ensures consistent product quality and operational reliability. This innovation plays a pivotal role in advancing semiconductor technology, driving progress across the industry and supporting sustainable production practices.