Selecting the right chamber lids is crucial for ensuring optimal performance and safety in various applications. A well-chosen lid not only prevents debris and contaminants from entering but also provides secure access for maintenance and inspection. For underground systems, chamber lids must comply with safety regulations to minimize risks and maintain structural integrity. The material, size, and design of the chamber lids directly impact their durability and functionality. By prioritizing these factors, users can achieve cost-effective solutions that enhance efficiency while adhering to industry standards.

要点

- Choose the right material for your chamber lids based on environmental conditions and load requirements to ensure durability and functionality.

- Consider the frequency of access needed; removable lids are ideal for regular maintenance, while fixed lids offer security for less accessible areas.

- Accurate measurements are crucial for selecting chamber lids; ensure the lid fits properly to prevent contamination and structural issues.

- Evaluate load capacity and pressure ratings to select lids that can safely support expected traffic and environmental pressures.

- Prioritize ease of use and maintenance features, such as ergonomic designs and corrosion-resistant materials, to enhance operational efficiency.

- Balance initial costs with long-term savings by investing in high-quality lids that reduce replacement and maintenance expenses.

- Research manufacturer reputation and support services to ensure you choose reliable products backed by expert assistance.

Understanding Chamber Lids

What Are Chamber Lids?

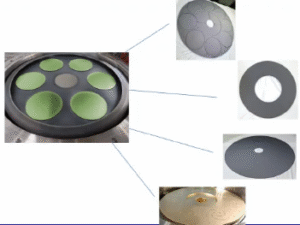

Chamber lids serve as protective covers for access points to underground systems, such as inspection chambers and drainage systems. These lids prevent debris, contaminants, and unauthorized access while ensuring the safety of individuals and the structural integrity of the system. Typically made from durable materials like cast iron, galvanized steel, or high-density polyethylene (HDPE), chamber lids are designed to withstand heavy loads and harsh environmental conditions.

Inspection chambers, for instance, often feature sectional designs with a base, risers, and a manhole cover. The risers connect to the base using rubber seals, creating a secure and watertight joint. Manhole covers, a common type of chamber lid, are large enough to allow human access for maintenance and inspection tasks. Their robust construction ensures they remain in place even under the pressure of passing traffic or adverse weather conditions.

Why Are Chamber Lids Important?

Chamber lids play a critical role in maintaining the functionality and safety of underground systems. They protect the internal components of inspection chambers, such as drainage pipes, from external elements like dirt, water, and debris. By doing so, they help prevent blockages and system failures, which could lead to costly repairs or environmental hazards.

Safety is another key factor. Chamber lids prevent accidental falls into open chambers and deter unauthorized access, reducing the risk of injury or tampering. For systems located in high-traffic areas, lids must meet stringent load-bearing requirements to ensure they can handle the weight of vehicles without shifting or breaking.

Additionally, chamber lids contribute to the efficiency of maintenance operations. Their design allows for easy removal and reinstallation, enabling quick access to the chamber for inspections or repairs. Specialized lids, such as those with noise-dampening features or locking mechanisms, further enhance their functionality by addressing specific operational needs.

"The choice of chamber lid material and design depends on factors such as the chamber’s size, depth, and intended use. Selecting the right lid ensures long-term performance and compliance with safety standards."

Types of Chamber Lids

Fixed vs. Removable Lids

Fixed lids remain permanently attached to the chamber structure. These lids provide a secure and tamper-resistant solution for applications where frequent access is unnecessary. Their design minimizes the risk of misplacement or unauthorized removal, making them ideal for high-security environments. Fixed lids often feature robust materials to withstand environmental stress and heavy loads.

Removable lids, on the other hand, offer flexibility and convenience. Users can easily detach these lids to access the chamber for maintenance, inspection, or repairs. This type suits applications requiring regular access, such as drainage systems or utility chambers. Manufacturers often design removable lids with ergonomic handles or lifting points to simplify handling. Selecting between fixed and removable lids depends on the frequency of access and the specific operational requirements.

Manual vs. Automatic Lids

Manual lids require physical effort to open and close. These lids are cost-effective and straightforward, making them a popular choice for standard applications. They often include features like lifting keys or handles to assist with operation. However, manual lids may not be suitable for scenarios where quick or frequent access is necessary, as they can demand significant effort.

Automatic lids incorporate advanced mechanisms for effortless operation. These lids use hydraulic, pneumatic, or electric systems to open and close with minimal human intervention. Automatic lids enhance efficiency and safety, especially in industrial or high-traffic settings. They reduce the risk of injury during operation and save time during maintenance tasks. While automatic lids offer numerous benefits, their higher cost and complexity may limit their use to specialized applications.

Specialized Lids for Unique Applications

Certain applications require chamber lids with unique features to address specific challenges. For example, noise-dampening lids reduce sound levels in urban areas or near residential zones. Lockable lids enhance security by preventing unauthorized access, making them suitable for sensitive installations. Ventilated lids allow airflow while maintaining protection, which is essential for chambers housing electrical or mechanical equipment.

In addition, some lids are designed to blend seamlessly with their surroundings. Decorative lids, for instance, integrate with landscaping or architectural elements to maintain aesthetic appeal. Heavy-duty lids cater to extreme conditions, such as high-pressure environments or areas with heavy vehicular traffic. Choosing a specialized lid ensures optimal performance and addresses the unique demands of the application.

Materials Used in Chamber Lids

Common Materials and Their Benefits

The materials used in chamber lids significantly influence their durability, functionality, and suitability for specific applications. Manufacturers often select materials based on the environmental conditions and load requirements of the chamber. Below are some of the most common materials and their benefits:

Cast Iron

Cast iron is a traditional choice for chamber lids due to its exceptional strength and durability. It can withstand heavy loads, making it ideal for high-traffic areas such as roads and industrial zones. Cast iron lids resist wear and tear over time, ensuring long-term performance. However, their weight can make handling and installation more challenging.

Galvanized Steel

Galvanized steel offers a balance between strength and weight. The zinc coating on the steel provides excellent corrosion resistance, which is essential for outdoor or wet environments. These lids are lighter than cast iron, making them easier to handle while still maintaining robust load-bearing capabilities.

High-Density Polyethylene (HDPE)

HDPE is a lightweight yet durable material commonly used for chamber lids in residential or low-traffic areas. It resists chemical corrosion and UV degradation, making it suitable for harsh environmental conditions. HDPE lids are also easier to install and maintain due to their reduced weight.

複合材料

Composite lids combine materials like fiberglass and resin to create a lightweight yet strong product. These lids are non-conductive, making them ideal for electrical or telecommunications chambers. They also offer excellent resistance to corrosion and weathering, ensuring longevity in demanding environments.

アルミ

Aluminum lids are lightweight and corrosion-resistant, making them suitable for applications requiring frequent access. Their ease of handling and aesthetic appeal make them a popular choice for urban or architectural settings.

"The choice of material directly impacts the lid’s performance and lifespan. For example, upgrading a heated pressure chamber lid to a more robust design can enhance its durability and functionality."

Choosing the Right Material for Your Needs

Selecting the appropriate material for a chamber lid requires careful consideration of the specific application and environmental factors. Here are some key points to guide the decision-making process:

Load Requirements

Assess the expected load on the chamber lid. For high-traffic areas, materials like cast iron or galvanized steel are better suited due to their superior load-bearing capacity. In contrast, HDPE or composite materials work well for lighter loads.

Environmental Conditions

Consider the environment where the chamber lid will be installed. For corrosive or wet conditions, materials like galvanized steel, HDPE, or composites provide better resistance to rust and degradation. In areas with extreme temperatures, materials with thermal stability, such as aluminum or composites, perform more reliably.

Frequency of Access

Determine how often the chamber will need to be accessed. Lightweight materials like HDPE or aluminum are easier to handle and reinstall, making them ideal for applications requiring frequent maintenance.

Special Features

Evaluate any additional requirements, such as non-conductivity for electrical chambers or noise-dampening properties for urban settings. Composite materials often meet these specialized needs effectively.

予算の制約

Balance the cost of the material with its performance and lifespan. While cast iron and automatic lids may have higher upfront costs, their durability can result in long-term savings by reducing replacement and maintenance expenses.

By aligning the material choice with the operational demands and environmental conditions, users can ensure optimal performance and cost-effectiveness. Consulting with experts or suppliers can further refine the selection process, ensuring the chosen material meets all safety and functional requirements.

Sizing and Load Capacity of Chamber Lids

Measuring for a Proper Fit

Accurate measurements are essential when selecting chamber lids to ensure a proper fit. A lid that does not align with the chamber opening can compromise its functionality and safety. To begin, measure the diameter or dimensions of the chamber opening. Use precise tools like measuring tapes or calipers to avoid errors. For irregularly shaped openings, take multiple measurements to account for variations.

The shape of the chamber opening also plays a critical role. Round, square, or rectangular openings require lids designed specifically for those shapes. A mismatch between the lid and the chamber can lead to poor sealing, increasing the risk of contamination or structural failure. Additionally, consider the depth of the chamber. Deeper chambers may require lids with reinforced edges or additional support features.

"Proper sizing ensures the lid fits securely, preventing movement or displacement under pressure or load."

Manufacturers often provide sizing charts or guidelines to assist in selecting the correct lid. Consulting these resources can simplify the process and reduce the likelihood of errors. For unique or custom applications, working with a supplier to design a tailored solution may be necessary.

Understanding Load Capacity and Pressure Ratings

Load capacity is a critical factor in choosing chamber lids, as it determines the weight the lid can safely support. Selecting a lid with inadequate load capacity can lead to structural damage, safety hazards, and costly repairs. To ensure durability and compliance, always evaluate the expected load on the lid.

Start by identifying the type of traffic or weight the lid will encounter. For pedestrian areas, lids with lower load capacities may suffice. In contrast, high-traffic zones with vehicles or heavy machinery require lids designed to withstand significant pressure. Manufacturers categorize lids into load classes, such as light, medium, or heavy-duty, to help users make informed decisions.

"The golden rule is to choose a higher load rating when in doubt. Overestimating the load requirement ensures safety and prevents premature wear."

Pressure ratings also play a role in applications involving sealed or pressurized chambers. These ratings indicate the maximum pressure the lid can endure without failure. For chambers exposed to high-pressure environments, such as industrial systems, selecting a lid with an appropriate pressure rating is essential.

To enhance safety and functionality, consider the following tips:

- Assess Traffic Conditions: Determine the type and frequency of traffic over the chamber. Heavy-duty lids are ideal for roads and industrial sites, while lighter lids suit residential areas.

- Account for Environmental Factors: Evaluate external conditions, such as temperature fluctuations or corrosive environments, which may affect the lid’s performance.

- Consult Experts: Seek guidance from manufacturers or industry professionals to select a lid that meets both load and pressure requirements.

By prioritizing proper sizing and load capacity, users can ensure the longevity and reliability of their chamber lids. These considerations not only enhance safety but also reduce maintenance costs and downtime.

Additional Factors to Consider When Choosing Chamber Lids

Ease of Use and Maintenance

Ease of use plays a significant role in the selection of chamber lids, especially for applications requiring frequent access. A well-designed lid should allow users to open, close, and secure it without excessive effort. Features such as ergonomic handles, lifting points, or integrated hinges simplify operation and reduce the risk of injury during handling. For example, removable lids with built-in lifting mechanisms can save time and effort during maintenance tasks.

Maintenance requirements also influence the long-term usability of chamber lids. Materials resistant to corrosion, wear, and environmental damage require less upkeep, ensuring consistent performance over time. Galvanized steel and composite materials, for instance, offer excellent durability with minimal maintenance needs. Regular inspections and cleaning further extend the lifespan of the lid, preventing issues like rust or structural degradation.

"Selecting a lid that balances ease of use with low maintenance ensures operational efficiency and reduces downtime."

When evaluating options, users should consider how the lid’s design and material align with their maintenance capabilities and operational demands. Consulting with manufacturers or suppliers can provide additional insights into the ease of use and care requirements for specific products.

Cost and Budget Considerations

Cost remains a critical factor when choosing chamber lids. The initial purchase price often reflects the material, design, and features of the lid. While budget constraints may limit options, investing in a high-quality lid can lead to long-term savings by reducing replacement and repair costs. For example, cast iron lids may have a higher upfront cost but offer exceptional durability, making them a cost-effective choice for high-traffic areas.

Users should also account for installation and maintenance expenses. Lightweight materials like HDPE or aluminum reduce labor costs during installation, while corrosion-resistant options minimize ongoing maintenance expenses. Automatic lids, though more expensive, enhance efficiency and safety, potentially offsetting their higher cost through operational benefits.

To make informed decisions, users can follow these steps:

- Assess Total Cost of Ownership: Evaluate the initial cost alongside long-term expenses, including maintenance and potential replacements.

- Prioritize Quality Over Price: Opt for durable materials and reliable designs to avoid frequent repairs or replacements.

- Seek Expert Advice: Consult with suppliers or industry professionals to identify cost-effective solutions that meet specific requirements.

"Balancing cost with performance ensures users achieve value for money without compromising safety or functionality."

Manufacturer Reputation and Support

The reputation of the manufacturer significantly impacts the quality and reliability of chamber lids. Established manufacturers with a proven track record often deliver products that meet industry standards and customer expectations. Researching customer reviews, certifications, and case studies can provide valuable insights into a manufacturer’s credibility.

Support services offered by the manufacturer also play a crucial role. Reliable manufacturers provide comprehensive warranties, technical assistance, and after-sales support to address any issues that may arise. For instance, a manufacturer offering detailed installation guides and maintenance tips ensures users can maximize the performance of their chamber lids.

"Partnering with a reputable manufacturer guarantees access to high-quality products and dependable support."

Users should prioritize manufacturers known for their expertise and commitment to customer satisfaction. Building a relationship with a trusted supplier ensures access to tailored solutions and expert guidance throughout the product’s lifecycle.

Selecting the best chamber lids requires a clear understanding of their types, materials, sizing, and other critical factors. Each decision should align with the specific needs of the application, ensuring safety, durability, and efficiency. Users benefit from consulting experts or suppliers to gain tailored recommendations and avoid costly mistakes. By prioritizing quality and functionality, they can achieve long-term performance and compliance with industry standards.

Explore available options today or contact a trusted supplier to find the ideal solution for your requirements.