In the competitive world of graphite rotors, three products stand out for their exceptional performance and reliability: Ningbo VET Energy Technology Co. Graphite Rotor, Pyrotek Graphite Rotor, and SGL Carbon Graphite Rotor. These products excel in the market due to their innovative designs and superior materials. The Ningbo VET Energy Technology Co. Graphite Rotor, for instance, is renowned for its durability and efficiency in graphite degassing rotor applications. Meanwhile, Pyrotek and SGL Carbon offer advanced solutions that cater to diverse industrial needs, ensuring optimal performance and longevity.

要点

- The Ningbo VET Energy Technology Co. Graphite Rotor is highly durable and efficient, making it ideal for demanding industrial applications like aluminum degassing.

- Pyrotek Graphite Rotor enhances kinetic mixing, effectively removing impurities from molten aluminum, which is crucial for high-quality production in automotive and aerospace sectors.

- SGL Carbon Graphite Rotor excels in extreme conditions, offering high-temperature resistance and structural integrity, making it suitable for industries requiring reliable performance.

- All three rotors provide cost-effective solutions by reducing maintenance needs and operational costs, ensuring long-term savings for businesses.

- Choosing the right graphite rotor depends on specific operational requirements, such as the type of industry and the conditions under which the rotor will be used.

- Graphite rotors play a vital role in improving the efficiency and quality of aluminum processing, benefiting sectors like automotive, aerospace, and electronics.

Product Overview

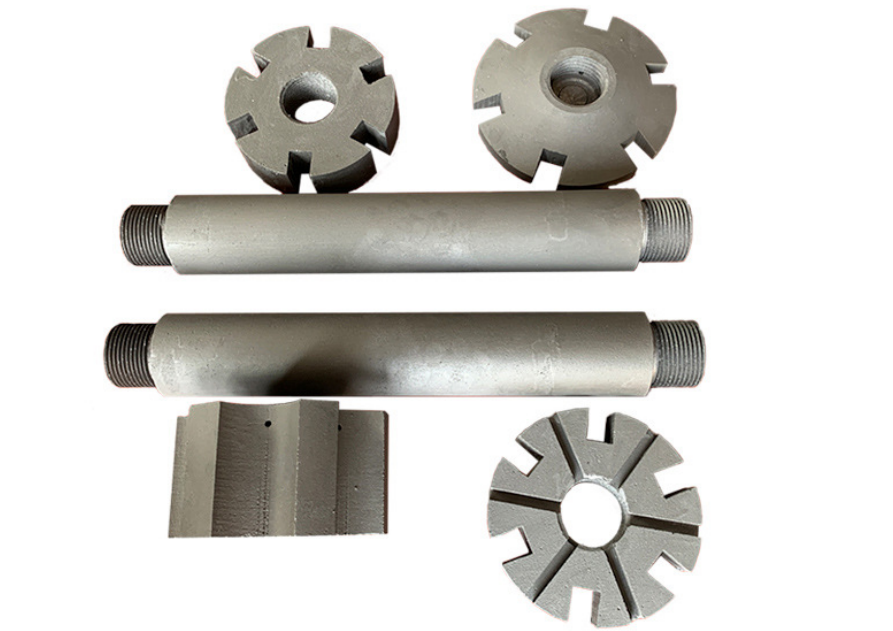

Ningbo VET Energy Technology Co. Graphite Rotor

主な特長

について Ningbo VET Energy Technology Co. Graphite Rotor stands out due to its exceptional durability and efficiency. This graphite rotor is crafted from high-purity graphite material, which ensures excellent thermal conductivity and corrosion resistance. Its robust mechanical strength makes it a reliable choice for demanding industrial applications. The rotor undergoes precise manufacturing processes and strict quality control, guaranteeing a long service life and consistent performance.

Specifications

- 素材: High-purity graphite

- 熱伝導率: Superior

- 耐食性: High

- 機械的強度: Robust

- アプリケーション: Ideal for aluminum degassing and other high-temperature operations

Pyrotek Graphite Rotor

主な特長

について Pyrotek Graphite Rotor is renowned for its advanced design, which enhances the kinetic mixing of metals during degassing operations. This rotor is specifically engineered to facilitate the removal of hydrogen and impurities from molten aluminum, ensuring high-quality end products. Its lightweight construction and superior strength make it suitable for various industrial sectors, including automotive and aerospace.

Specifications

- 素材: High-grade graphite

- 熱伝導率: Exceptional

- Weight: Lightweight

- 強み: Superior

- アプリケーション: Primarily used in aluminum foundries for degassing

SGL Carbon Graphite Rotor

主な特長

について SGL Carbon Graphite Rotor offers innovative solutions tailored to diverse industrial needs. Known for its high-temperature resistance and structural integrity, this rotor excels in extreme conditions. It efficiently disperses purifying gases within the aluminum melt, facilitating thorough degassing and purification processes. This capability is crucial for achieving high-quality aluminum products.

Specifications

- 素材: Advanced graphite composite

- 熱抵抗: High

- 構造の整合性: Maintained under extreme conditions

- ソリューション: Optimal in degassing operations

- アプリケーション: Suitable for aerospace, automotive, and energy sectors

比較分析

Performance

Ningbo VET Energy Technology Co. Graphite Rotor

について Ningbo VET Energy Technology Co. Graphite Rotor excels in performance due to its high-purity graphite composition. This rotor demonstrates superior thermal conductivity, which enhances the efficiency of degassing operations. Its robust mechanical strength ensures consistent performance even under demanding conditions. Users report that this graphite rotor maintains optimal functionality over extended periods, making it a preferred choice for industrial applications.

Pyrotek Graphite Rotor

について Pyrotek Graphite Rotor offers advanced performance features that cater to the needs of aluminum foundries. Its design facilitates effective kinetic mixing, crucial for removing hydrogen and impurities from molten aluminum. This rotor’s lightweight construction does not compromise its strength, allowing it to perform efficiently across various sectors. Industries such as automotive and aerospace benefit from its ability to produce high-quality end products.

SGL Carbon Graphite Rotor

について SGL Carbon Graphite Rotor stands out for its performance in extreme conditions. Its high-temperature resistance and structural integrity make it ideal for challenging environments. This rotor efficiently disperses purifying gases within the aluminum melt, ensuring thorough degassing and purification. Its performance is particularly valued in sectors requiring high-quality aluminum, such as aerospace and energy.

耐久性

Ningbo VET Energy Technology Co. Graphite Rotor

Durability defines the Ningbo VET Energy Technology Co. Graphite Rotor. Crafted from high-purity graphite, it withstands the rigors of industrial use. Its corrosion resistance and mechanical strength contribute to a long service life, reducing the need for frequent replacements. This durability makes it a cost-effective solution for businesses seeking reliable graphite rotor options.

Pyrotek Graphite Rotor

について Pyrotek Graphite Rotor combines lightweight design with durability. Its high-grade graphite material ensures longevity, even in high-temperature environments. Users appreciate its ability to maintain structural integrity over time, which minimizes operational disruptions. This durability makes it a valuable asset in industries where consistent performance is critical.

SGL Carbon Graphite Rotor

について SGL Carbon Graphite Rotor offers exceptional durability, thanks to its advanced graphite composite material. It maintains structural integrity under extreme conditions, ensuring a long operational life. This rotor’s durability is particularly beneficial in sectors like aerospace and energy, where reliability is paramount.

費用対効果

Ningbo VET Energy Technology Co. Graphite Rotor

について Ningbo VET Energy Technology Co. Graphite Rotor provides a cost-effective solution for industrial applications. Its durability and efficiency reduce maintenance costs and downtime, offering significant savings over time. Businesses benefit from its long service life, which translates to lower replacement expenses.

Pyrotek Graphite Rotor

Cost-effectiveness characterizes the Pyrotek Graphite Rotor. Its lightweight design and superior performance minimize energy consumption, leading to reduced operational costs. Industries value its ability to deliver high-quality results without incurring excessive expenses, making it a smart investment.

SGL Carbon Graphite Rotor

について SGL Carbon Graphite Rotor offers cost-effectiveness through its durability and efficiency. Its ability to perform under extreme conditions reduces the need for frequent replacements, lowering overall costs. This rotor’s efficiency in degassing operations also contributes to cost savings, making it an attractive option for budget-conscious businesses.

User Reviews

Ningbo VET Energy Technology Co. Graphite Rotor

Users consistently praise the Ningbo VET Energy Technology Co. Graphite Rotor for its outstanding performance and reliability. Many industrial operators highlight its exceptional durability, noting that it withstands rigorous conditions without compromising efficiency. One user mentioned, “The rotor’s high-purity graphite material ensures it lasts longer than other options we’ve tried.” This sentiment echoes across various reviews, emphasizing the rotor’s ability to maintain optimal functionality over extended periods. Additionally, users appreciate the cost-effectiveness of this product, as its long service life reduces the need for frequent replacements.

Pyrotek Graphite Rotor

について Pyrotek Graphite Rotor receives commendations for its advanced design and lightweight construction. Users in the aluminum foundry sector particularly value its ability to enhance kinetic mixing during degassing operations. A review from an aerospace industry professional stated, “The Pyrotek rotor significantly improved our production quality by efficiently removing impurities.” This rotor’s lightweight nature does not compromise its strength, making it a preferred choice for industries requiring high-quality end products. Users also note its energy efficiency, which contributes to reduced operational costs.

SGL Carbon Graphite Rotor

について SGL Carbon Graphite Rotor garners positive feedback for its high-temperature resistance and structural integrity. Users in sectors like aerospace and energy appreciate its performance in extreme conditions. One user remarked, “The SGL rotor’s ability to disperse purifying gases effectively has been crucial for our operations.” This rotor’s durability and efficiency in degassing processes make it a valuable asset for businesses aiming to achieve high-quality aluminum products. Reviews often highlight its cost-effectiveness, as its robust design minimizes the need for replacements, thereby reducing overall expenses.

Use Cases

Ningbo VET Energy Technology Co. Graphite Rotor

理想的な適用

について Ningbo VET Energy Technology Co. Graphite Rotor finds its ideal applications in industries requiring robust and efficient degassing solutions. This graphite rotor excels in aluminum smelting operations, where it plays a crucial role in removing hydrogen and impurities from molten aluminum. Its high-purity graphite composition ensures excellent thermal conductivity, making it suitable for high-temperature environments. Industries such as automotive and aerospace benefit significantly from its durability and efficiency, as these sectors demand high-quality aluminum products. The rotor’s ability to withstand rigorous conditions without compromising performance makes it a preferred choice for businesses seeking reliable and cost-effective solutions.

Pyrotek Graphite Rotor

理想的な適用

について Pyrotek Graphite Rotor is particularly well-suited for aluminum foundries, where its advanced design enhances kinetic mixing during degassing operations. This rotor’s lightweight construction and superior strength make it an excellent choice for industries that prioritize energy efficiency and high-quality end products. Automotive and aerospace sectors, in particular, appreciate its ability to efficiently remove impurities, resulting in improved production quality. The rotor’s performance in these demanding environments underscores its value as a versatile and effective solution for various industrial applications.

SGL Carbon Graphite Rotor

理想的な適用

について SGL Carbon Graphite Rotor offers exceptional performance in extreme conditions, making it ideal for sectors such as aerospace, automotive, and energy. Its high-temperature resistance and structural integrity ensure reliable operation in challenging environments. This rotor efficiently disperses purifying gases within the aluminum melt, facilitating thorough degassing and purification processes. Industries that require high-quality aluminum products, such as those in the energy sector, benefit from its durability and efficiency. The rotor’s ability to maintain optimal functionality under demanding conditions highlights its suitability for diverse industrial applications.

In conclusion, the graphite rotor plays a pivotal role in enhancing the efficiency and quality of aluminum and zinc manufacturing processes. The Ningbo VET Energy Technology Co., Pyrotek, and SGL Carbon graphite rotors emerge as top contenders due to their exceptional durability, thermal conductivity, and structural integrity. These products cater to diverse industrial needs, ensuring optimal performance in demanding environments. Industries such as automotive, aerospace, and electronics benefit significantly from these rotors’ ability to maintain high-quality standards. Readers should consider these options based on specific operational requirements to achieve superior results.

よくあるご質問

What are graphite rotors used for?

Graphite rotors play a crucial role in aluminum alloy smelting equipment. They facilitate degassing and fluxing operations, which are essential for removing hydrogen and impurities from molten aluminum. This process enhances the quality of the final aluminum product, making graphite rotors indispensable in industries like automotive and aerospace.

How do graphite rotors improve efficiency in aluminum processing?

Incorporating graphite degassing rotors into aluminum processing operations significantly boosts efficiency and product quality. These rotors enhance kinetic mixing, ensuring thorough removal of impurities. As a result, industries experience streamlined operations and improved outcomes, leading to higher-quality aluminum products.

Why is customization important for graphite rotors?

Customization offers a competitive edge in the graphite rotor market. Tailored solutions meet specific client needs, strengthening market position. Manufacturers can increase market share and foster customer loyalty by providing specialized solutions for niche industries or specific applications.

What makes Ningbo VET Energy Technology Co. Graphite Rotor stand out?

The Ningbo VET Energy Technology Co. Graphite Rotor is renowned for its durability and efficiency. Crafted from high-purity graphite, it offers excellent thermal conductivity and corrosion resistance. Its robust mechanical strength ensures reliable performance in demanding industrial applications, making it a preferred choice for many businesses.

How does the Pyrotek Graphite Rotor enhance production quality?

The Pyrotek Graphite Rotor features an advanced design that enhances kinetic mixing during degassing operations. This capability efficiently removes hydrogen and impurities from molten aluminum, resulting in high-quality end products. Industries such as automotive and aerospace benefit from its ability to improve production quality.

What are the advantages of using SGL Carbon Graphite Rotor?

The SGL Carbon Graphite Rotor excels in extreme conditions due to its high-temperature resistance and structural integrity. It efficiently disperses purifying gases within the aluminum melt, facilitating thorough degassing and purification processes. This rotor’s performance is particularly valued in sectors requiring high-quality aluminum, such as aerospace and energy.

How does the graphite rotor market remain competitive?

The graphite rotor market remains competitive by offering tailored solutions for specific applications. Understanding product dynamics through market research and competitive analysis is essential for maintaining competitiveness. Manufacturers that provide customized solutions can ensure exceptional quality and customer satisfaction.

What industries benefit most from graphite rotors?

Industries such as automotive, aerospace, and electronics benefit significantly from graphite rotors. These sectors demand high-quality aluminum products, which graphite rotors help achieve by enhancing the efficiency and quality of aluminum manufacturing processes. The rotors’ ability to maintain high standards makes them valuable assets in these industries.

Are there any environmental benefits to using graphite rotors?

Graphite rotors contribute to environmental sustainability by improving the efficiency of aluminum processing operations. Their ability to remove impurities and enhance product quality reduces waste and energy consumption. This efficiency aligns with industries’ goals to minimize environmental impact while maintaining high production standards.