LED epitaxial susceptor plays a vital role in the epitaxial growth process. It acts as a stable platform for depositing semiconductor layers, ensuring precision during LED manufacturing. This component directly influences the quality of the layers by maintaining uniformity and stability throughout the process. Manufacturers rely on its design and material properties to achieve high-quality LEDs. Its contribution to efficient production makes it indispensable in modern semiconductor technology.

要点

- LED epitaxial susceptors are crucial for ensuring high-quality semiconductor layers during LED manufacturing by providing a stable and controlled environment.

- The combination of graphite and silicon carbide in susceptor design enhances thermal conductivity and durability, essential for withstanding high temperatures.

- Uniform heat distribution and precise gas flow are vital for achieving optimal performance in LED production, directly impacting energy efficiency.

- Mechanical durability of susceptors reduces the need for frequent replacements, contributing to cost-effective and consistent production processes.

- LED epitaxial susceptors are not only used in LED manufacturing but also play a significant role in other semiconductor applications, such as power electronics and optoelectronic devices.

- Emerging technologies like micro-LEDs require even greater precision from susceptors, highlighting the need for ongoing advancements in their design and materials.

- Investing in high-quality LED epitaxial susceptors can lead to enhanced brightness and longevity of LEDs, making them a smart choice for manufacturers aiming to meet industry standards.

Technical Specifications of LED Epitaxial Susceptors

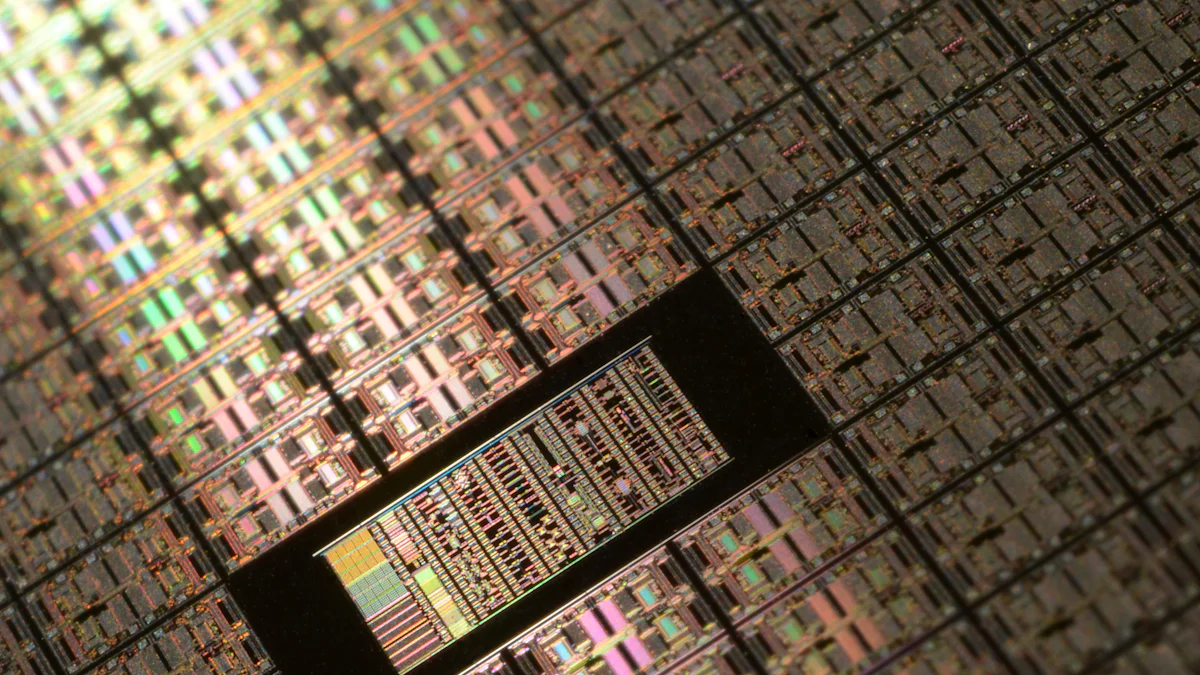

Material Composition and Design

LED epitaxial susceptors rely on advanced materials to meet the demands of the epitaxial growth process. Graphite serves as a common base material due to its excellent thermal properties. Manufacturers often enhance graphite with silicon carbide (SiC) coatings, which improve durability and thermal conductivity. This combination ensures the susceptor can withstand high temperatures while maintaining structural integrity.

The design of an LED epitaxial susceptor focuses on achieving uniform heat distribution. A consistent thermal profile is essential for producing high-quality semiconductor layers. Engineers incorporate features that promote laminar gas flow, reducing turbulence during the deposition process. This design approach minimizes defects in the epitaxial layers and enhances overall production efficiency.

Thermal and Mechanical Properties

Thermal stability is a critical attribute of LED epitaxial susceptors. These components must endure extreme temperatures without deforming or losing functionality. High thermal conductivity allows them to transfer heat efficiently, ensuring uniform temperature across the substrate surface. This property directly impacts the quality of the epitaxial layers.

Mechanical durability also plays a significant role. LED epitaxial susceptors face constant exposure to wear and tear during manufacturing. Resistance to mechanical stress ensures a longer lifespan and reduces the need for frequent replacements. This reliability contributes to cost-effective and consistent production processes.

Compatibility with Epitaxial Growth Processes

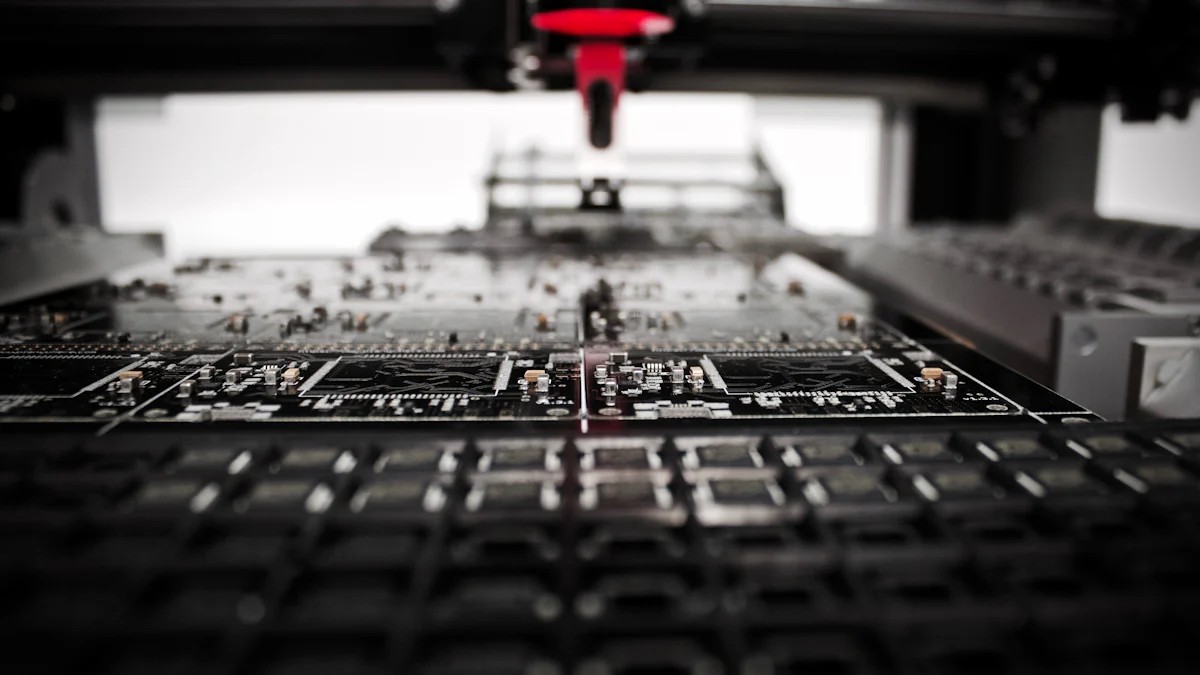

LED epitaxial susceptors are specifically designed to support metal-organic chemical vapor deposition (MOCVD). This process requires precise control over temperature and gas flow to achieve optimal results. The susceptor’s material and design ensure compatibility with these stringent requirements.

Maintaining process stability is another key function of the susceptor. It helps regulate the deposition environment, ensuring uniformity in the semiconductor layers. Consistent layer thickness and material quality are essential for producing high-performance LEDs. The susceptor’s role in this process underscores its importance in modern semiconductor manufacturing.

Applications of LED Epitaxial Susceptors

Role in LED Manufacturing

LED epitaxial susceptors play a pivotal role in the production of high-efficiency LEDs. They provide a stable and controlled environment for the epitaxial growth process, which is essential for achieving optimal performance. By ensuring uniform heat distribution and precise gas flow, these components contribute to the creation of LEDs with superior energy efficiency. Manufacturers rely on their ability to maintain consistent conditions during deposition to produce LEDs that meet industry standards.

The importance of LED epitaxial susceptors extends to achieving precise layer thickness and material quality. These factors directly influence the optical and electrical properties of LEDs. A well-designed susceptor minimizes defects in the semiconductor layers, resulting in devices with enhanced brightness and longevity. This precision underscores their critical role in modern LED manufacturing.

Use in Other Semiconductor Industries

Beyond LED production, LED epitaxial susceptors find applications in other semiconductor industries. Power electronics benefit from their use in the growth of materials like Gallium Nitride (GaN), which is known for its high efficiency and thermal stability. These materials are essential for devices such as transistors and diodes used in power conversion systems.

Optoelectronic devices also rely on LED epitaxial susceptors for the growth of Indium Phosphide (InP) and similar materials. These devices, including lasers and photodetectors, require high-quality epitaxial layers to function effectively. The susceptor’s ability to support precise deposition processes makes it indispensable in these advanced technologies.

Emerging Applications and Innovations

Emerging technologies like micro-LEDs present new opportunities for LED epitaxial susceptors. Micro-LEDs, known for their compact size and high brightness, demand even greater precision during manufacturing. Susceptors designed for these applications must meet stricter requirements for uniformity and stability. Their role in enabling the production of next-generation displays highlights their evolving importance.

Advancements in susceptor materials and designs continue to enhance their performance. Researchers are exploring new coatings and structural improvements to increase durability and thermal efficiency. These innovations aim to meet the growing demands of the semiconductor industry while reducing production costs. The ongoing development of LED epitaxial susceptors ensures their relevance in future technologies.

LED epitaxial susceptors play a vital role in LED manufacturing and the broader semiconductor industry. Their ability to ensure precise layer deposition and maintain process stability makes them indispensable for high-quality production. These components enhance efficiency by supporting uniform heat distribution and reliable performance. Advancements in susceptor technology promise to drive innovation, enabling next-generation applications like micro-LEDs. As the demand for advanced semiconductors grows, the development of more durable and efficient susceptors will remain essential for meeting industry needs.