LEDのエピタキシャルの感受性は半導体の製造の礎石として機能し、エピタキシャル成長の間に精密な熱制御を保障します。 均一な熱分布を提供することで、高度なデバイスに不可欠な高品質の半導体層の創造を可能にします。 消費者用電子機器や照明などの産業は、これらのコンポーネントに依存して、効率的で信頼性の高い技術に対する需要が高まっています。 LEDのepitaxyの感受性のための全体的な市場は、約で評価しました 1億米ドル 2022年、高効率な照明システムとそれを超えてイノベーションとパフォーマンスを駆動する上で重要な役割を果たしています.

要点

- 半導体製造時に均一な熱分布を維持するためには、LEDのエピタキシャルの感受性は、高品質で欠陥のない層を保証します.

- シリコンカーバイドコートグラファイトなどの先端材料の使用は、半導体デバイスにおける効率性の向上と欠陥の低減につながる熱伝導性を高めます.

- 熱制御を最適化することによって、LEDのエピタキシャルの感受性は製造業プロセスの重要な省エネそして費用効率に貢献します.

- これらの感受性装置によって作り出される良質の半導体の層はより明るく、長持ちし、より多くのエネルギー効率が良いLEDsの消費者電子工学および自動車のような企業に寄与します.

- 半導体製造の未来は、AIやIoTなどの新興技術の要求に応えるために、自動化や先進材料などのスセプター技術の革新に頼ります.

- 現代の技術の進歩を把握し、持続可能で高性能な解決のための押しのために重要なのは、LEDのエピタキシャルの感受性の役割を理解します.

LEDエピタキシャルスセプターとは何ですか?

定義と目的

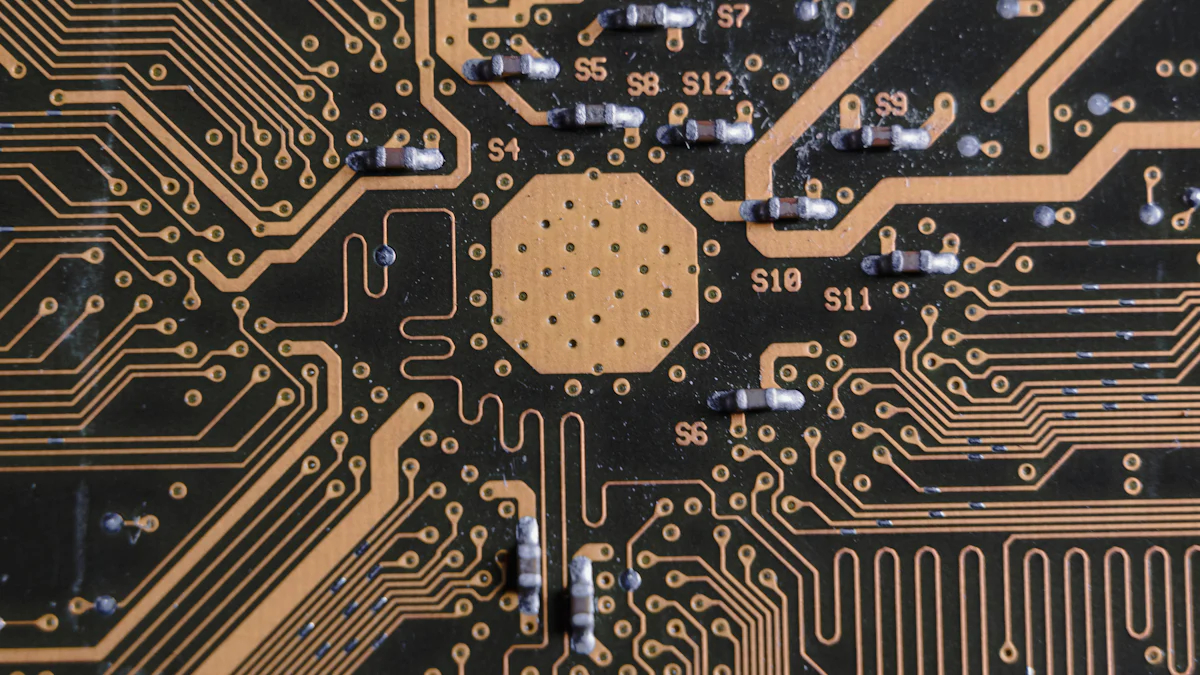

LED のエピタキシャルの感受性は半導体の製造プロセスの必須用具として役立つ。 これらのコンポーネントは、エピタキシャル成長のための安定した管理された環境を提供し、高品質の半導体層を作成する重要なステップです。 均一な熱分布を確保するために、欠陥のない効率的なデバイスを製造するために不可欠である材料の正確な堆積を有効にします.

LEDのエピタキシャルの感受性のロールはウエファーを支えるだけを越えて伸びます。 高温プロセス中の熱安定性を維持し、エピタキシャル層の品質を損なう可能性がある変動を防ぎます。 この安定性は、コンシューマーエレクトロニクス、自動車、高度な照明システムなどの業界にとって重要な役割を果たしています.

「熱安定性は、半導体製造のエキスパートが指摘したエピタキシャル成長の背骨です。 それなしでは、近代的なデバイスに必要な精度がほぼ不可能になります.

LEDエピタキシャルサスセプターの仕組み

LEDのエピタキシャルの感受性は化学蒸気の沈殿物(CVD)およびエピタキシー プロセスの中心で作動します。 これらのプロセスは、材料の薄い層を基板に沈着させ、目的の半導体構造を作成します。 受容体は電磁エネルギーを吸収し、熱に変換し、化学反応に必要な温度を発揮します。 この熱は均等性および精密を保障する表層の制御された成長を、促進します.

物質的な特性はLEDのエピタキシャルの感受性の有効性で重要な役割を担います。 高い熱伝導性はウエハ全体の熱配分を保障し、次元の精密は温度の勾配を最小にします。 例えば、, 炭化ケイ素(SiC)上塗を施してあるグラファイトの感受性 優秀な熱特性および耐久性が原因で広く利用されます。 これらの先端材料は製造プロセスの効率を高めます、欠陥を減らし、全体的な製品品質を改善します.

これらの受容体の重要性は、過小評価できません。 それらはウエハの物理的構造をサポートしているだけでなく、全体のエピタキシャル成長プロセスを最適化するだけでなく、。 この最適化は、LEDやその他の半導体デバイスを適切に形成し、高機能技術の需要を増大させます.

LEDエピタキシャルサスセプターが半導体を改善する方法 ソリューション

高められた熱配分

半導体製造のコーナーストーンは均一熱分布です。 LED のエピタキシャルの感受性はウエファーの表面を渡る一貫した温度制御を維持することで包んでいます。 この均等性は、エピタキシャル層が均等に成長することを保証します。これは、高品質の半導体の製造に不可欠です。 この精密な熱規制がなければ、メーカーは不均等な沈着を危険にさらし、デバイスの性能を損なう欠陥を引き起こします.

熱グラデーション、またはウエハ全体の温度の変化、多くの場合、構造的な矛盾をもたらします。 LEDのエピタキシャルの感受性は炭化ケイ素上塗を施してあるグラファイトのような材料を利用することによってこれらの勾配を防ぎます。 これらの材料は熱伝導性が非常に高く、熱を効率的に分配することを可能にします。 温度の格差を除去することにより、感受性は欠陥の可能性を減らし、各層が高度なアプリケーションに必要な厳格な品質基準を満たしていることを確認します.

「一貫した熱分布は、単なる技術的要件ではありません。業界の専門家によると、欠陥のない半導体製造の基礎です.

改善された物質的な質

LEDのエピタキシャルの感受性のロールは熱管理を越えて伸びます。 欠陥のない、高性能な半導体層の創造に直接貢献します。 エピタキシャル成長のための安定した環境を提供することによって、スセプターは材料の精密な沈着を可能にしま、優秀な構造完全性を層に終ります。 この精度は、高効率や耐久性を要求するLEDやその他のデバイスを製造するために不可欠です.

高品質の半導体層は、LEDの性能を高め、より明るく、長持ちし、よりエネルギー効率を高めます。 これらの改良は、消費者の電子機器や自動車などの業界において特に重要であり、信頼性と効率性がパラマウントされています。 たとえば、スマートフォンやテレビのLEDは、スセプターが有効にする高度な材料品質から恩恵を受け、活気あるディスプレイと寿命を延ばします.

改善された材料の質の影響は照明解決にまた拡張します。 スマートな球根およびフラッドライトのような高性能LEDの照明プロダクト、製造の間に作成される欠陥なしの層に性能をowe。 これらの製品は、エネルギーを削減し、持続可能でエネルギー効率の高い技術のためのグローバル・プッシュと一直線に合わせ、エネルギーを消費します.

省エネとコスト効率

LEDのエピタキシャルの感受性はまた製造業の間にエネルギー消費を減らすことのpivotal役割を担います。 精密な熱制御を維持する能力は最適温度を達成するために必要なエネルギーを最小にします。 この効率は、環境フットプリントを削減しながら、より効果的にリソースを割り当てることができるメーカーにとって重要なコスト節約につながります.

物質廃棄物は、受容体がコスト効率を促す別の領域です。 均一な堆積と欠陥の防止を確保することで、作業や廃棄物の必要性を軽減します。 生産コストを削減するだけでなく、持続可能な製造慣行をサポートしています.

LEDのエピタキシャルの感受性の使用の経済的利点はエンド ユーザーにまた拡張します。 これらのコンポーネントで製造されたデバイスは、多くの場合、より少ないエネルギー要件を持ち、運用コストを削減します。 住宅照明や産業用途でも、効率的な製造プロセスによって達成されるコスト節約は、最終的に消費者や企業にも利益をもたらします.

LEDエピタキシャルサスセプターの現実世界的アプリケーション

LEDの適用 製造業

LEDのエピタキシャルの感受性は現代照明および表示技術のために必要である高性能LEDsの生産でpivotal役割を果たします。 これらのコンポーネントは、エピタキシャル成長プロセス中に精密な熱制御を確保し、欠陥のない半導体層の生成を可能にします。 この精密はLEDの性能に直接影響を与え、より明るく、よりエネルギー効率が高く、長持ちさせます。 消費者用電子機器などの産業は、スマートフォン、テレビ、ラップトップなどの高品質のディスプレイの需要が高まっています.

Micro-LED技術の採用により、LEDのエピタキシャルの感受性の重要性がさらに強調されています。 優れた明るさとエネルギー効率で知られるマイクロLEDは、製造中にさらに高い精度が求められます。 Susceptorsは、拡張現実のヘッドセットや次世代テレビなどのデバイスにディスプレイ技術を革命化させる、これらの最先端LEDを生成するために必要な熱安定性を提供します。 マイクロLEDの開発を支えることで、スセプターは高度な照明やディスプレイソリューションの進化に貢献します.

「LED技術の未来は、業界リーダーによると、エピタキシャル・スセプターのようなコンポーネントが不可欠である精密製造にあります.

より広い半導体 アプリケーション

LEDの製造業を越えて、LEDのエピタキシャルの感受性は力電子工学および光電子工学装置の適用を見つけます。 電動車および再生可能エネルギーシステム、例外的な熱および電気特性の要求の半導体で使用される電力電子工学。 スセプターは、製造中に均一な熱分布と材料の品質を確保することにより、これらの高性能半導体の生産を可能にします。 この機能は、持続可能なエネルギーソリューションにとって重要な効率的で信頼性の高い電力システムの開発をサポートしています.

レーザーおよびフォトディテクターを含む光電子工学装置はまたLEDのエピタキシャルの感受性によって提供される精密からの寄与します。 これらの装置は欠陥のない半導体の層を最適の性能を達成するために要求します。 スセプターは、そのようなレイヤーを作成するために必要な制御された環境を提供し、光電子コンポーネントの機能と耐久性を強化します.

LEDのエピタキシャルの感受性の貢献は次世代半導体の革新に拡張します。 人工知能(AI)やモノのインターネット(IoT)などの新興技術は、加工・コネクティビティの最先端半導体に依存しています。 Susceptorsは、これらの半導体の製造を、AI主導のデバイスとIoTアプリケーションにおける画期的な方法を提案し、エピタキシャル成長プロセスを最適化することで促進します.

「半導体の革新は分野の専門家によって指摘されるように「明日の技術のための部品の作成を可能にするLEDのエピタキシャルの受容器のような精密用具によって、決まります.

LEDエピタキシャルサスセプター技術の進歩と未来の可能性

スセプター素材のイノベーション

先進材料の開発は、LEDエピタキシャルスセプターの設計と機能性に革命を起こしています。 これらのうち、, 炭化ケイ素(SiC)上塗を施してあるグラファイト ゲームチェンジャーとして立ちます。 この材料は、SiCの耐久性と耐熱性でグラファイトの卓越した熱伝導性を兼ね備えています。 製造業者は、高温プロセス中に精密な熱制御を実現し、一貫した性能と半導体層の欠陥を減らすために、この組み合わせに依存しています.

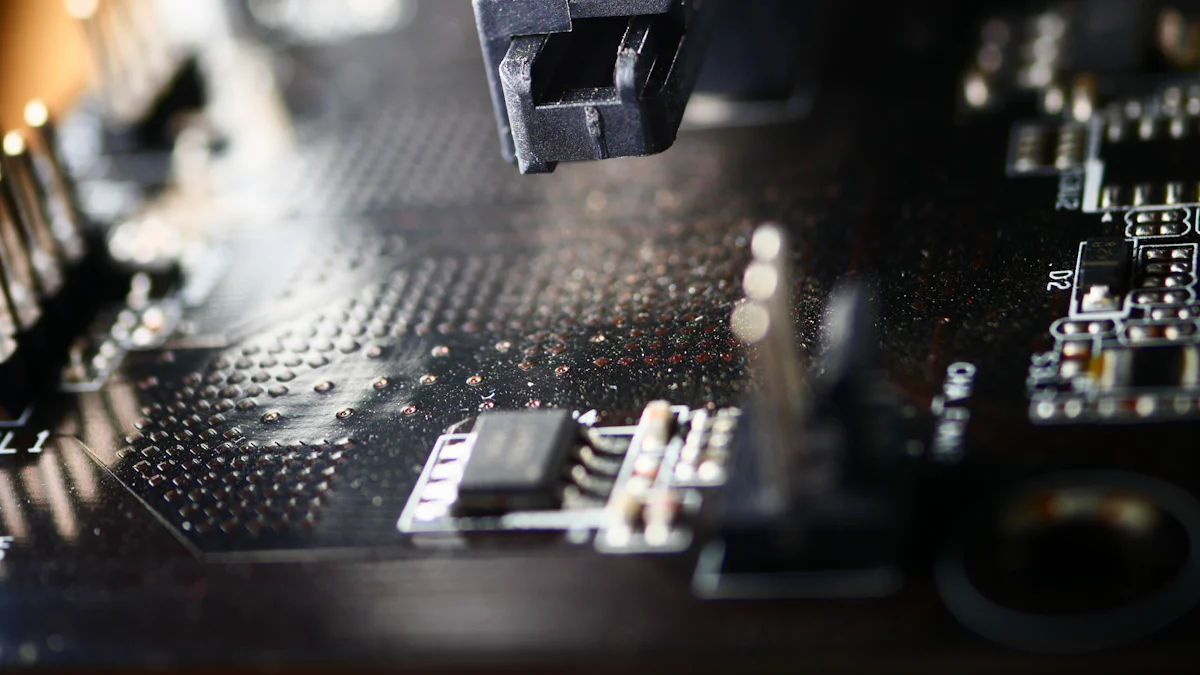

特殊なコーティングの統合により、スセプターの能力をさらに高めます。 これらのコーティングは熱安定性を改善し、感受性が構造の完全性を損なうことなく極端な条件に耐えることを可能にします。 たとえば、半導体ウェーハ処理で使用されるスセプターのための特許取得済みの設計は、熱応力を最小限にしながら均一な熱分布を維持することの重要性を強調しています。 このイノベーションにより、エピタキシャル成長プロセスは、製造要求が増加しても効率的で信頼性を維持します.

業界の専門家による「スセプター素材の高度化は、半導体製造の品質と効率性に直接影響します。」 最先端の材料を採用することにより、メーカーは、高性能機器の需要が高まっています.

半導体の未来の動向 製造業

半導体製造の未来は、人工知能(AI)やモノのインターネット(IoT)などの新興技術のニーズに応えるための生産のスケールアップに依存しています。 LEDのエピタキシャルの感受性はこの拡張で重要な役割を果たします。 精密な熱制御を維持する能力は、AI主導のデバイスやIoTアプリケーションに電力を供給するために不可欠である欠陥のない半導体の生産を保証します。 これらの技術が進化し続けていく中で、高品質な半導体の需要は高まります.

オートメーションと人工知能は、スセプターの設計とパフォーマンスを変革するだけでなく、. 高度なアルゴリズムは、製造プロセスを最適化し、比類のない精度でスセプターの作成を可能にします。 これらのイノベーションは、最終製品の全体的な品質を強化しながら、生産時間とコストを削減します。 たとえば、自動システムは、各コンポーネントが厳格な業界標準を満たしていることを確認します.

「AIと自動化の融合は、受容体製造の重要な飛躍を前方に表す」と、分野における主要な研究者が指摘する。 このアプローチは、効率性を向上させるだけでなく、半導体技術の新たな可能性を捉える方法にもなります.

LEDのエピタキシャルの感受性の技術の進歩は半導体の製造の未来を形作ることの重要性を強調します。 革新的な材料と自動化を取り入れることで、業界はかつてないレベルの効率とパフォーマンスを実現することができます.

LED のエピタキシャルの感受性は精密な熱配分、優秀な材料の質および重要な省エネを通した半導体の製造の礎石として立ちます。 LEDおよび半導体製造における役割は、高機能技術に対する需要の高まりに取り組むことの重要性を強調しています。 業界がエネルギー効率の高いソリューションにシフトするにつれて、これらのコンポーネントはメーカーが欠陥のない信頼性の高いデバイスを実現することができます。 スセプター材料と設計の継続的な革新は、半導体産業の未来を形作り、効率と性能の進歩を促進します。 現代の技術の進化を理解するために価値を認識することは不可欠です.