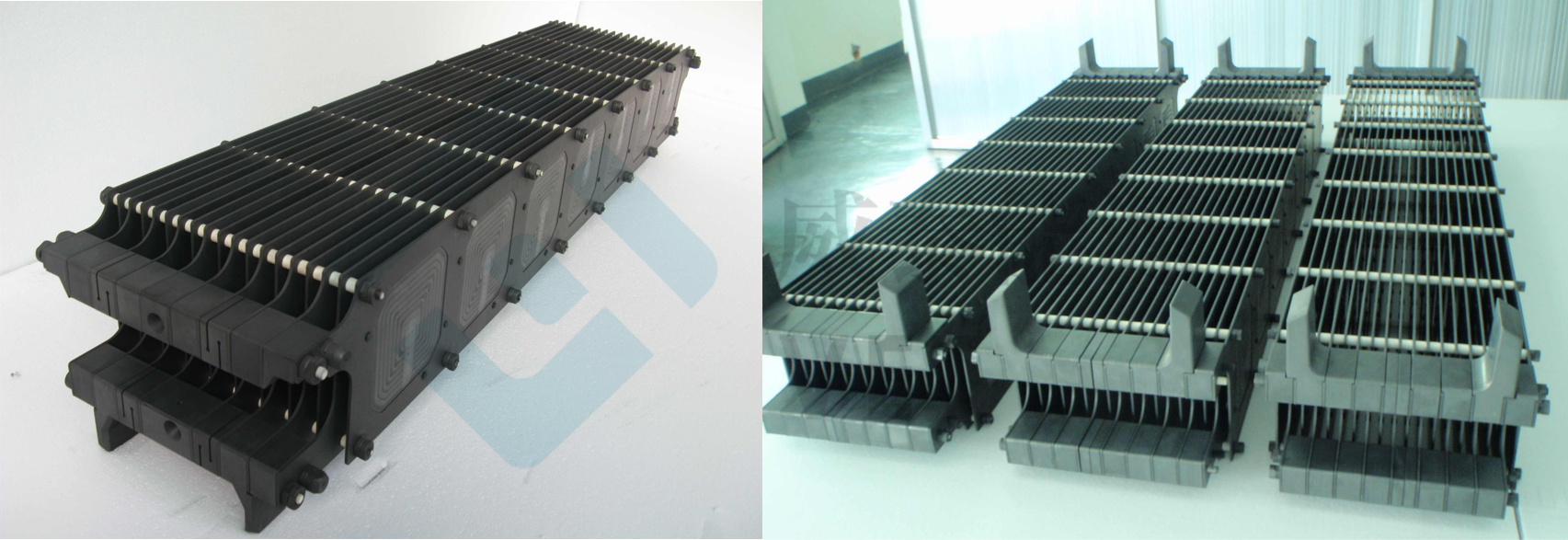

Solar cell production faces constant challenges in efficiency, cost, and technical precision. You need solutions that not only enhance performance but also streamline manufacturing processes. PECVD graphite boats have emerged as a game-changer in this field. These advanced tools ensure precise thin-film deposition, critical for improving solar cell efficiency. VET Energy, a trusted PECVD Graphite Boat Carrier Manufacturer, delivers cutting-edge solutions tailored to meet your production needs. Their innovative graphite boats redefine reliability and performance, helping you overcome the toughest obstacles in solar manufacturing.

要点

- PECVD graphite boats enhance solar cell efficiency by ensuring precise and uniform thin-film deposition, crucial for optimal energy absorption.

- These advanced carriers offer superior thermal stability, allowing them to withstand high temperatures without deformation, which is essential for maintaining production quality.

- Using PECVD graphite boats can significantly reduce material waste and energy consumption, leading to lower operational costs and a more sustainable manufacturing process.

- The durability of PECVD graphite boats minimizes downtime and maintenance needs, ensuring a steady workflow and helping manufacturers meet production targets.

- Investing in high-quality PECVD graphite boats can maximize your return on investment by reducing replacement costs and improving overall production efficiency.

- Choosing a reliable manufacturer like VET Energy ensures access to custom solutions and ongoing support, enhancing your production capabilities and competitiveness in the solar market.

Challenges in Solar Cell Production

Increasing Demand for High-Efficiency Solar Cells

Need for precise and uniform thin-film deposition.

The demand for high-efficiency solar cells continues to grow as renewable energy becomes a global priority. To achieve this efficiency, you must ensure precise and uniform thin-film deposition during production. Thin films, such as silicon nitride, play a critical role in reducing sunlight reflection and enhancing energy absorption. Any inconsistency in the deposition process can lead to performance issues. You need tools that guarantee accuracy and reliability to meet these stringent requirements.

Challenges in scaling production to meet global demand.

As the world shifts toward sustainable energy, the pressure to scale solar cell production increases. Meeting this demand requires advanced manufacturing processes that maintain quality while increasing output. Traditional methods often struggle to keep up with the pace of global needs. You face the challenge of balancing speed and precision without compromising the performance of the final product.

Cost Pressures in Solar Manufacturing

Reducing material waste and energy consumption.

Cost efficiency is a constant concern in solar manufacturing. You must minimize material waste and energy consumption to remain competitive. Inefficient processes lead to higher expenses and reduced profitability. By adopting innovative solutions, you can optimize resource usage and lower operational costs, ensuring a more sustainable production cycle.

Balancing quality with affordability.

Producing high-quality solar cells at an affordable price is another significant challenge. Customers demand reliable and efficient products, but cost constraints often limit your options. Striking the right balance between quality and affordability requires advanced tools and materials that deliver consistent results without inflating production costs.

Technical Limitations in Current Processes

Issues with thermal stability and contamination.

Thermal stability is crucial in solar cell manufacturing, especially during high-temperature processes like PECVD. Traditional carriers often fail to withstand these conditions, leading to deformation and contamination. Contaminants can compromise the efficiency and lifespan of solar cells. You need solutions that maintain stability and purity throughout the production cycle.

Limitations of traditional carriers in high-temperature environments.

Traditional carriers struggle in high-temperature environments, which are common in solar cell production. These carriers often degrade or lose their structural integrity, causing delays and increasing maintenance costs. To overcome this, you require carriers designed specifically for high-temperature applications, ensuring durability and consistent performance.

How PECVD Graphite Boats Address These Challenges

優れた熱安定性

Withstanding high temperatures without deformation.

You need tools that can endure extreme heat during solar cell production. PECVDグラファイトボート excel in this area.

Ensuring consistent performance over multiple cycles.

Consistency is key in solar manufacturing. PECVD graphite boats deliver reliable performance across multiple production cycles. Their superior thermal stability minimizes wear and tear, reducing the need for frequent replacements. This durability ensures that your production line operates efficiently, saving you time and resources.

Enhanced Process Efficiency

Uniform thin-film deposition for higher cell efficiency.

Achieving uniform thin-film deposition is critical for producing high-efficiency solar cells. PECVD graphite boats provide the precision needed for this process. Their design ensures even distribution of materials, resulting in consistent thin-film layers. This uniformity enhances the energy absorption capabilities of solar cells, improving their overall performance.

Reduced downtime due to durable and reliable materials.

Downtime disrupts production and increases costs. PECVD graphite boats minimize this risk. Their robust construction reduces the likelihood of damage or failure during operation. By using these reliable carriers, you can maintain a steady workflow and meet production targets without unnecessary delays.

汚染防止

Non-reactive properties of graphite reduce impurities.

Contamination can compromise the quality of solar cells. PECVD graphite boats address this issue with their non-reactive properties. The high-purity graphite material prevents chemical reactions that could introduce impurities. This feature ensures that your solar cells meet the highest standards of quality and efficiency.

Improved yield and product quality.

Higher yields mean greater profitability. PECVD graphite boats contribute to this by reducing defects caused by contamination or inconsistent processes. Their precision and reliability result in better-quality solar cells, helping you achieve higher output with fewer rejected products. This improvement directly impacts your bottom line and strengthens your position in the competitive solar market.

Benefits of Using PECVD Graphite Boats

Cost Savings

Longer lifespan reduces replacement costs.

You need tools that last longer to reduce frequent replacements. PECVD graphite boats offer exceptional durability, ensuring they withstand the demanding conditions of solar cell production. Their robust construction minimizes wear and tear, allowing you to use them for extended periods without compromising performance. This longevity directly translates into lower replacement costs, helping you allocate resources more effectively.

Lower energy consumption during production.

Efficient energy usage is critical in solar manufacturing. PECVD graphite boats enhance energy efficiency by maintaining optimal thermal conductivity during high-temperature processes. This feature reduces the energy required to achieve desired results, lowering your operational costs. By using these advanced carriers, you can achieve significant energy savings while maintaining high production standards.

Improved Solar Cell Performance

Higher efficiency and reliability of finished cells.

The quality of your solar cells depends on the precision of the manufacturing process. PECVD graphite boats ensure uniform thin-film deposition, which enhances the efficiency of the finished cells. Their non-reactive properties prevent contamination, resulting in reliable and high-performing solar panels. With these boats, you can consistently produce cells that meet or exceed industry standards.

Better scalability for mass production.

Scaling production to meet growing demand requires reliable tools. PECVD graphite boats support mass production by maintaining consistent performance across multiple cycles. Their durability and precision allow you to increase output without sacrificing quality. This scalability ensures you can meet market demands while maintaining a competitive edge.

Environmental Advantages

Reduced material waste and energy usage.

Sustainability is a priority in modern manufacturing. PECVD graphite boats help you reduce material waste by ensuring precise and efficient processes. Their ability to maintain thermal stability and prevent contamination minimizes defects, leading to fewer discarded products. Additionally, their energy-efficient design supports eco-friendly production practices, aligning with global sustainability goals.

Supporting sustainable manufacturing practices.

Adopting PECVD graphite boats demonstrates your commitment to sustainable manufacturing. These carriers are designed to optimize resource usage and minimize environmental impact. By integrating them into your production line, you contribute to the advancement of renewable energy while reducing your carbon footprint. This approach not only benefits the environment but also enhances your reputation as a responsible manufacturer.

Why Choosing the Right PECVD Graphite Boat Carrier Manufacturer Matters

Expertise in Graphite Engineering

Ensuring precision and quality in design.

Precision plays a vital role in solar cell production. A reliable manufacturer ensures that every PECVD graphite boat meets exact specifications. This precision guarantees consistent performance during the manufacturing process. You benefit from tools that maintain accuracy, even under demanding conditions. High-quality design minimizes errors, helping you achieve superior results in your solar cell production.

Custom solutions tailored to production needs.

Every production line has unique requirements. A trusted PECVD graphite boat carrier manufacturer offers custom solutions to meet your specific needs. They analyze your processes and provide tailored designs that enhance efficiency. Customization ensures that the graphite boats integrate seamlessly into your operations. This approach optimizes performance and helps you overcome production challenges effectively.

Commitment to Quality and Innovation

Use of advanced materials and manufacturing techniques.

The right manufacturer prioritizes quality by using 新素材. High-purity graphite ensures durability and reduces contamination risks.

Ongoing support and maintenance services.

A dependable manufacturer provides more than just products. They offer ongoing support to ensure your equipment performs optimally. Maintenance services help you address wear and tear before it impacts production. This proactive approach minimizes downtime and extends the life of your graphite boats. You can rely on their expertise to keep your operations running smoothly.

Long-Term Cost and Performance Benefits

Reliable products reduce operational risks.

Operational risks can disrupt production and increase costs. High-quality PECVD graphite boats reduce these risks by delivering consistent performance. Their durability minimizes the chances of failure during critical processes. You can focus on meeting production targets without worrying about unexpected breakdowns. Reliable tools ensure a stable and efficient manufacturing environment.

Maximizing return on investment in production equipment.

Investing in durable and efficient equipment pays off in the long run. PECVD graphite boats from a trusted manufacturer offer exceptional value. Their extended lifespan reduces replacement costs, while their efficiency lowers energy consumption. These benefits maximize your return on investment. You save resources while maintaining high production standards, ensuring long-term success in solar manufacturing.

PECVD graphite boats play a vital role in addressing the challenges of solar cell production. They enhance efficiency, reduce costs, and improve product quality, making them indispensable for modern solar manufacturing. By choosing a reliable PECVDグラファイトボート carrier Manufacturer like VET Energy, you gain access to advanced solutions tailored to your needs.

よくあるご質問

What is a PECVD graphite boat?

A PECVDグラファイトボート is a high-performance carrier used in the plasma-enhanced chemical vapor deposition (PECVD) process.

How does a PECVD graphite boat improve solar cell production?

PECVD graphite boats improve solar cell production by offering superior thermal stability, precise thin-film deposition, and contamination prevention. These features ensure consistent performance, reduce material waste, and enhance the overall efficiency of solar cells.

Why is thermal stability important in solar manufacturing?

Thermal stability ensures that carriers like PECVD graphite boats can withstand high temperatures without deforming. This stability prevents disruptions in the production process and maintains the precision required for high-quality solar cells.

What makes VET Energy’s PECVD graphite boats unique?

VET Energy’s PECVD graphite boats use high-purity imported graphite, ensuring low impurity content and exceptional durability.

Can PECVD graphite boats reduce production costs?

Yes, PECVD graphite boats reduce production costs by minimizing material waste, lowering energy consumption, and offering a longer lifespan. Their durability reduces the need for frequent replacements, saving you money over time.

How do PECVD graphite boats prevent contamination?

PECVD graphite boats prevent contamination through their non-reactive properties and high-purity materials. These features reduce the risk of impurities entering the production process, ensuring higher yields and better-quality solar cells.

Are PECVD graphite boats suitable for mass production?

Yes, PECVD graphite boats are ideal for mass production. Their durability and consistent performance allow you to scale operations without compromising quality. They support high-efficiency manufacturing processes, making them suitable for large-scale solar cell production.

How do I choose the right PECVD graphite boat manufacturer?

Choose a manufacturer with expertise in graphite engineering, a commitment to quality, and a track record of innovation. Look for custom solutions tailored to your production needs and ongoing support services to ensure long-term success.

What maintenance do PECVD graphite boats require?

PECVD graphite boats require minimal maintenance due to their durable construction. Regular inspections can help identify wear and tear early, ensuring optimal performance. Partnering with a reliable manufacturer like VET Energy ensures access to maintenance support when needed.

How do PECVD graphite boats contribute to sustainability?

PECVD graphite boats contribute to sustainability by reducing material waste and energy usage. Their efficient design supports eco-friendly manufacturing practices, aligning with global efforts to promote renewable energy and reduce environmental impact.

製品の詳細については、下記までお問い合わせください。 steven@china-vet.com またはウェブサイト: www.vet-china.com.