シリコンカーバイド(SiC)のカンチレバーパドルは、半導体および太陽光発電製造における重要な役割を果たしています。 これらのコンポーネントは、正確なウェーハの取り扱いと極端な条件下での安定性を維持します。 高温抵抗と耐薬品性は、高度な製造工程で欠かせません。 SiC材料は、石英と比較して、製品の品質を高め、特に太陽光発電分野での運用コストを削減します。 周辺特許 SiCカンチレバーパドル 既存システムとの相性を向上し、斬新なデザインを導入することでイノベーションを推進します。 知的財産を保護しながら技術の進歩を促進し、これらの産業の継続的な発展を保証します.

要点

- SiCカンチレバーパドルは、半導体および太陽光発電製造における精密なウェーハ処理に不可欠であり、極端な条件下での安定性を保証します.

- SiCパドルの高温抵抗(最大1300°C)は、より大きなウエファーが効率的に処理できるように、生産性を高め、運用コストを削減します.

- SiCパドルの化学的安定性と耐久性は、汚染リスクとメンテナンスニーズを最小限に抑え、製品の品質と運用効率の向上に貢献します.

- 最近の特許は、「二段」のハンドルのような革新的な設計を導入し、既存のシステムとの互換性を改善し、機械性能を高めます.

- SiCカンチレバーパドル 生産プロセスの合理化と製造ラインの破壊を減らす、自動化システムにますます統合されます.

- 再生可能エネルギーおよび電気自動車の新興アプリケーションは、SiCパドルの汎用性を強調し、バッテリー技術とソーラーパネルの生産の進歩をサポートします.

- 精密エンジニアリングと大型ウェーハ生産へのトレンドは、現代の製造におけるSiC材料の成長の重要性を強調しています.

SiCカンチレバーパドルを理解する

SiCカンチレバーパドルとは?

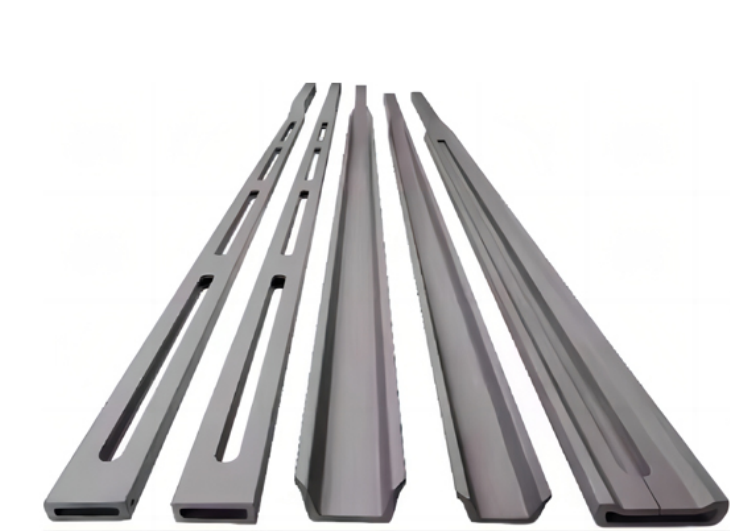

シリコンカーバイド(SiC)のカンチレバーパドルは、半導体および太陽光発電業界で重要なコンポーネントとして機能します。 これらのパドルは、高温プロセス中にウェーハの正確な処理と転送を容易にします。 半導体製造では、ウェーハボートを拡散炉に積み込む上で重要な役割を果たし、正確な位置決めと安定性を保証します。 同様に、太陽電池製造では、単結晶および多結晶シリコンをコーティングし、太陽光エネルギーシステムの効率性に貢献します.

設計の SiCカンチレバーパドル 機能性と信頼性を優先します。 彼らのカンチレバーの構造は継ぎ目が無いウエファーのローディングおよび荷を下すことを可能にしま、損傷の危険を最小にします。 極端な条件下で構造的整合性を維持することにより、これらのパドルは、要求の厳しいアプリケーションで一貫した性能を保証します。 既存のシステムとの互換性により、高度な製造環境に欠かせない、その実用性をさらに高めます.

CantileverのパドルのSiC材料の主特徴そして利点

高温抵抗と耐久性

SiCカンチレバーパドルは1000°Cから1300°Cまでの高温への例外的な抵抗を、示します。この特性は拡散炉および他の熱処理装置の使用のためにそれらを理想的にします。 変形する材料とは異なり、SiCは極端な熱への長期暴露の下でも、その形状と強度を維持します。 既存の炉管を使用してメーカーがより大きいウエファーを生産し、生産性を改善し、コストを削減することができます.

SiCの耐久性もカンチレバーパドルの寿命を延ばします。 高純度のSiC材料は摩耗を抵抗し、引き裂き、時間をかけて一貫した性能を保証します。 この耐久性は交換の頻度を減らし、維持費を下げ、生産ラインのダウンタイムを最小限に抑えます.

ハーシュ環境における化学的安定性と性能

SiCカンチレバーパドル 過酷な処理環境に適した、驚くべき化学的安定性を発揮します。 半導体や太陽光発電製造に使用される反応化学物質の暴露による腐食・劣化に抵抗します。 この抵抗は、パドルが構造の整合性と機能性を維持していることを保証します.

また、SiCの熱膨張係数は、半導体プロセスで一般的に使用されるLPCVDコーティングのそれと密接に整列します。 熱応力や汚染のリスクを低減し、メンテナンスと清掃サイクルを延長します。 汚染物質の最小化とプロセス精度の確保により、SiCカンチレバーパドルは、製品の品質と運用効率の向上に貢献します.

プロダクト ハイライト: : : ザ・オブ・ザ・ 高い純度SiC Cantilever パドル 比類のない熱安定性と耐食性を提供し、ウェーハ転送と高温処理の信頼できる選択にします。 SiCコーティングおよびSiCコーティングキャリアソリューションの詳細をご覧ください 詳しくはこちら.

SiCカンチレバーパドルの特許

SiCカンチレバーパドルの最近の注目すべき特許

特許は、SiCカンチレバーパドルの設計と機能を強化する上で重要な役割を果たしています。 1つの重要な特許は、シリコンカーバイドカンチレバーパドルを半導体ウェーハ処理用に設計しました。 このイノベーションは、さまざまな重量負荷で最適な偏向特性を達成することに重点を置いています。 設計はハンドルの転移の地帯によって分けられる大口径セクションおよび小径セクションの明瞭なセクションと「2段」ハンドルを組み込みます。 この構造は、既存のクランプシステムとの互換性を高め、現在の製造セットアップにシームレスな統合を保証します.

このような特許は、SiCカンチレバーパドルの機械的性能を向上させるだけでなく、ウェーハ処理における実用的な課題にも対処します。 構造要素の改良により、高温環境における信頼性と効率性の向上に貢献します。 半導体・太陽光発電業界における技術の進歩を牽引する知的所有権の重要性を根ざした課題です.

主なイノベーション これらの特許で強調表示

ノベル設計と製造工程

最近の特許は、SiCカンチレバーパドルの設計と生産に新しいアプローチを強調しています。 反応焼結などの高度な製造技術の導入により、優れた熱・機械的特性を持つパドルの創造を可能にしました。 これらの方法は、パドルが極端な条件下で構造的整合性を維持し、重要なプロセス中に変形または故障の危険性を減らすことを保証します.

また、前述の「2段」ハンドルのような革新的なデザインは、SiCカンチレバーパドルの機能性を高めます。 パドルの幾何学を最適化することにより、メーカーはより良い重量分布と処理精度を向上させることができます。 これらの進歩は、パドルのパフォーマンスを高めるだけでなく、寿命を延ばすだけでなく、エンドユーザーのメンテナンスコストを削減します.

高度なシステムへの統合により、パフォーマンスを強化

特許は、SiCカンチレバーパドルの統合を高度なシステムに強調しています。 たとえば、これらのパドルは、精密と信頼性がパラマウントされる自動ウェーハローディングシステムでますます使用されています。 既存の装置との両立性は生産ラインの破壊を最小にする滑らかな操作を保障します.

また、SiCカンチレバーパドルの化学的安定性と高温抵抗により、LPCVD(低圧化学蒸気蒸着)プロセスでの使用に最適です。 汚染や熱的ストレスのリスクを低減し、一貫した製品品質を保証します。 これらのパドルを最先端のシステムに組み込むことにより、半導体および太陽光発電用途における高効率・生産性が向上します.

プロダクト ハイライト: 探索 SiCコーティング そして SiCの上塗を施してあるキャリア 高温環境での耐久性と性能の向上のためのソリューション。 もっと詳しく 詳しくはこちら.

アプリケーションと業界への影響

SiCカンチレバーパドルの現在の適用

SiCのカンチレバーのパドルは半導体および光起電の製造業で必要になりました。 半導体ウェーハ処理では、ウェーハを拡散炉に搬送する際に重要な役割を果たしています。 高温の安定性は精密な位置を保障し、高温操作の間に変形を防ぎます。 この信頼性は、先進半導体デバイスの製造に不可欠であるウェーハローディングシステムの効率性を高めます.

太陽光発電業界では、SiCカンチレバーパドルは、モノクリスタルと多結晶シリコンのコーティングをサポートします。 これらのパドルは、均一なコーティングプロセスを保証する、極端な熱の下で構造的完全性を維持します。 ウェーハの転写とサポートで、高品質の太陽電池の生産に貢献します。 それらの耐薬品性は、汚染リスクを最小限に抑え、太陽光発電材料の純度を維持するために不可欠です.

科学的研究ファインディング:

- “SiCカンチレバーパドル 半導体・太陽電池業界におけるウェーハ搬送用 ウェーハを溶融炉に搬送することの重要性を強調.

- 「半導体加工装置における高純度SiCカンチレバーパドル」 高温環境での耐久性と耐食性を強調します.

潜在的な将来の使用と業界動向

再生可能エネルギー・電気自動車の活用事例

SiCカンチレバーパドルの汎用性は、再生可能エネルギーおよび電気自動車の新興アプリケーションにそれらを配置します。 効率的なエネルギー貯蔵システムの需要が高まるにつれて、これらのパドルは次世代電池技術の製造業を支えることができます。 過酷な条件に耐える能力は、電気自動車電池で使用される高性能材料を進化させるプロセスに適しています.

再生可能エネルギーでは、SiCカンチレバーパドルは、先進的なソーラーパネル製造におけるアプリケーションを見つけることができる。 革新的なコーティング技術との相性は、太陽電池の効率性を高めることができます。 精密な材料の取り扱いを可能にすることにより、高温耐性の部品を必要とする濃縮太陽光発電システムの開発にも貢献することができました.

精密工学・先端製造の動向

精密工学は進化し続け、SiCカンチレバーパドルはこの傾向に合わせます。 メーカーは、強度と信頼性の両方を提供する材料を優先します。 SiCのパドルは例外的な熱安定性および化学抵抗を提供することによってこれらの要求を満たします。 自動システムへの統合により、先進的な製造技術への業界のシフトが反映されます.

精密工学のSiC材料の採用はまたより大きいウエファーの生産を支えます。 重い負荷の下で構造的整合性を維持することにより、これらのパドルは、製造業者が妥協することなく生産をスケールアップすることができます。 このトレンドは、半導体および太陽光発電業界における費用対効果の高いソリューションの必要性と整列します.

プロダクト ハイライト: 発見 SiCコーティング そして SiCの上塗を施してあるキャリア 高温環境でのパフォーマンス向上のためのソリューション もっと詳しく 詳しくはこちら.

SiCカンチレバー パドルは、半導体製造と太陽光発電製造のコーナーストーンとして誕生しました。 高い純度、熱安定性および耐食性はプロセス正確さを保障し、製品品質を高めます。 特許は、イノベーションの推進、先進的なデザインと製造技術を導入し、効率性と信頼性を向上させました。 これらのパドルの統合は、最先端のシステムに重点を置きます。 業界が発展するにつれて、より広範な採用と新しいアプリケーションの可能性が拡大し続けています。再生可能エネルギーおよび精密工学の進歩の道を舗装します.

ツアー SiCコーティング そして SiCの上塗を施してあるキャリア 性能向上のためのソリューション 詳しくはこちら.

よくあるご質問

高純度SiCカンチレバーパドルとは何ですか?

高い純度 SiCカンチレバー パドルは、半導体加工機器の重要なコンポーネントです。 優れた熱安定性、耐食性、耐久性で知られる高純度の炭化ケイ素(SiC)材料から作られています。 このパドルは、高温プロセス中に精密なウェーハ転送とサポートを保証します。 その高度な特性は、プロセスの精度を維持し、要求の厳しい製造環境で製品品質を向上させるために不可欠です.

シリコンカーバイドカンチレバーパドルは、太陽電池の製造工程でどのように使用されますか?

太陽の光起電細胞の生産では、炭化ケイ素のcantileverのパドルは重要な役割を担います。 これらのパドルは、拡散やLPCVDなどのプロセスのための加熱炉にシリコンウェーハを運ぶと荷を下し、荷を下します。 炉管とウェーハの同心配列を確保することで、均一な拡散とパッシベーションを促進します。 極端な温度下での熱衝撃抵抗と非変形性は、太陽光発電製造の一貫した結果を達成するための信頼性を発揮します.

なぜシリコンカーバイド(SiC)は、カンチレバーパドルの他の材料よりも優先されますか?

シリコンカーバイド(SiC)は、水晶などの伝統的な材料と比較して優れた特性を提供します。 高温抵抗、化学的安定性、機械的強度は、過酷な環境での信頼性の高い性能を保証します。 SiCはまた変形および汚染に抵抗し、半導体および光起電工業の精密塗布のためにそれを理想的にします。 これらの属性はメンテナンスの必要性を減らし、カンチレバーパドルの長寿を高めます.

半導体製造におけるSiCカンチレバーパドルのメリットとは?

SiCのcantileverのパドルは半導体の製造で複数の利点を提供します。 構造的完全性を極端に保ち、拡散とLPCVDプロセスにおける正確なウェーハ処理を保証します。 それらの化学的安定性は汚染リスクを最小限に抑え、耐久性は交換頻度を削減します。 生産性の向上、運用コストの低減、製品品質の向上に貢献します.

SiCカンチレバーパドルを自動化システムに統合できますか?

はい、SiCのcantileverのパドルは自動ウエハのローディング システムと互換性があります。 堅牢な設計と精密な幾何学は、シームレスな統合を高度な製造セットアップに保証します。 この互換性は、効率を高め、生産ラインの破壊を削減し、近代的な半導体および光起電施設の好ましい選択にします.

高温環境に適したSiCカンチレバーパドルは?

SiCカンチレバーパドルは、熱安定性に優れた高温環境で優れています。 1000°から及ぶ温度に耐えます C~1300°C 強度を変形または失わないC。 このプロパティは、過熱への長期暴露中に一貫したパフォーマンスを保証します。拡散やLPCVDなどのプロセスに最適です.

SiCカンチレバーパドルは再生可能エネルギーの進歩にどのように貢献しますか?

SiCカンチレバーパドルは、太陽電池の効率的な生産を可能にし、再生可能エネルギーの進歩をサポートします。 高温および抵抗の化学劣化を扱う能力は均一コーティングおよび拡散プロセスを保障します。 これらのパドルは、高度なソーラーパネル製造および次世代バッテリー技術で新興アプリケーションの可能性も保持しています.

カンチレバーパドルの性能を高めるSiCコーティングの役割は何ですか?

SiCのコーティングは摩耗、腐食および熱圧力に対して付加的な保護を提供することによってcantileverのパドルの性能を高めます。 このコーティングはパドルの耐久性を改善し、寿命を延ばし、要求する環境の信頼できる操作を保障します。 詳しくはこちら SiCコーティング そして SiCの上塗を施してあるキャリア ソリューション 詳しくはこちら.

SiCカンチレバーパドルの使用に影響を与える業界動向はありますか?

精密工学および高度の製造業のための成長した要求はSiCのcantileverのかいの採用を運転します。 業界は、高い強度と信頼性で材料を優先し、SiCはこれらの要件を満たしています。 より大きなウェーハの生産への傾向は、SiCパドルの重要性を強調し、重負荷下での構造的整合性を維持し、半導体および太陽光発電分野における費用対効果の高いスケーリングをサポートします.

SiCカンチレバーパドルと関連ソリューションに関する詳しい情報はどこで入手できますか?

SiCカンチレバーパドルの詳細については、 SiCコーティング そして SiCの上塗を施してあるキャリア ソリューション、www.vet-china.comをご覧ください。 高温環境での性能と信頼性を向上できる先進材料のノウハウをご覧ください.

製品の詳細については、下記までお問い合わせください。 steven@china-vet.com またはウェブサイト: www.vet-china.com.