Silicon carbide tubes have become indispensable in high-temperature applications due to their remarkable properties. Industries such as power generation, chemical processing, and semiconductor manufacturing rely on these tubes for their exceptional thermal resistance and mechanical strength. The SiC Tube stands out for its ability to withstand extreme temperatures, ensuring durability and efficiency in demanding environments. Its chemical inertness further enhances its utility, making it a preferred choice for various industrial processes. As businesses continue to push the boundaries of performance, the demand for innovative materials like the Silicon Carbide Tube is set to rise.

要点

- Silicon carbide tubes excel in high-temperature applications due to their exceptional thermal conductivity, allowing for efficient heat transfer and improved energy utilization.

- とりあえず thermal shock resistance ensures reliability in environments with rapid temperature changes, making them ideal for industries like semiconductor manufacturing.

- The chemical inertness of silicon carbide tubes enhances their lifespan in harsh conditions, reducing maintenance costs and ensuring long-term reliability.

- Investing in silicon carbide tubes is cost-effective, as their durability minimizes the need for frequent replacements, leading to significant savings over time.

- Silicon carbide technology is evolving, with advancements in material science opening new applications in sectors like aerospace, automotive, and renewable energy.

- Choosing high-quality silicon carbide tubes from reputable manufacturers like Ningbo VET Energy Technology Co. guarantees performance that meets the rigorous demands of modern industrial applications.

- The growing demand for silicon carbide tubes across various industries highlights their importance in promoting energy efficiency and sustainability.

Properties of Silicon Carbide

高い熱伝導性

Silicon carbide tubes exhibit exceptional thermal conductivity, a property that significantly enhances their performance in high-temperature applications. This characteristic allows for efficient heat transfer, which is crucial in maintaining the stability of temperatures in various industrial processes. For instance, in power generation, the ability of a silicon carbide tube to conduct heat efficiently ensures that energy is utilized optimally, reducing waste and improving overall system efficiency.

科学的研究ファインディング:

- Silicon carbide’s thermal conductivity is comparable to that of diamond, making it one of the most effective materials for heat transfer.

- Its low thermal expansion coefficient further contributes to its stability under fluctuating temperatures.

Thermal Shock Resistance

The ability of silicon carbide tubes to withstand rapid temperature changes without cracking or deforming is another key advantage. This thermal shock resistance makes them ideal for environments where temperatures can vary suddenly and dramatically. For example, in semiconductor manufacturing, where processes often involve quick transitions between high and low temperatures, silicon carbide tubes maintain their integrity, preventing material failure and ensuring consistent production quality.

科学的研究ファインディング:

- Silicon carbide maintains structural integrity even at temperatures up to 1600°C.

- Its low thermal expansion minimizes the risk of cracking under thermal stress.

化学的不活性

Silicon carbide’s 化学不活性 is a critical property that extends its lifespan in harsh environments. It resists corrosion and chemical reactions, making it suitable for use in industries where exposure to aggressive chemicals is common. In chemical processing plants, silicon carbide tubes can handle corrosive substances like acids and alkalis without degrading, ensuring long-term reliability and reducing maintenance costs.

科学的研究ファインディング:

- Silicon carbide withstands chemical assault from a broad spectrum of corrosive materials, including molten salts and acids.

- Its resistance to chemical reactions makes it perfect for demanding chemical conditions.

The combination of these properties—high thermal conductivity, thermal shock resistance, and chemical inertness—makes silicon carbide tubes indispensable in high-temperature applications. Their ability to perform reliably under extreme conditions ensures that industries can operate efficiently and safely, pushing the boundaries of what is possible with traditional materials.

Benefits of Silicon Carbide Tubes in High-Temperature Applications

耐久性

Silicon carbide tubes exhibit remarkable durability, making them ideal for high-temperature applications. Their ability to withstand extreme conditions ensures a long lifespan, which is crucial for industries that operate under harsh environments. The mechanical strength of these tubes allows them to endure wear and abrasion, maintaining their integrity over time. This durability translates into cost-effectiveness, as businesses can rely on these tubes for extended periods without frequent replacements.

Long Lifespan Under Extreme Conditions: Silicon carbide tubes resist temperatures up to 2500°C, showcasing their unmatched durability. This resistance ensures that they remain functional even in the most demanding settings, reducing downtime and maintenance needs.

長期的な費用対効果: Investing in silicon carbide tubes proves economical in the long run. Their longevity minimizes the need for replacements, leading to significant savings on maintenance and operational costs.

ソリューション

The efficiency of silicon carbide tubes in industrial processes cannot be overstated. Their superior thermal properties enhance performance, making them indispensable in various high-temperature applications. These tubes facilitate improved energy utilization, contributing to both operational efficiency and environmental sustainability.

Improved Performance in Industrial Processes: Silicon carbide tubes offer excellent thermal conductivity, ensuring efficient heat transfer. This property enhances the performance of industrial systems, allowing them to operate at optimal levels.

Energy Savings Due to Superior Thermal Properties: The high thermal conductivity of silicon carbide tubes leads to energy savings. By optimizing heat transfer, these tubes reduce energy consumption, which not only lowers costs but also supports efforts to minimize carbon emissions.

The combination of durability and efficiency makes silicon carbide tubes a valuable asset in high-temperature applications. Their ability to perform reliably under extreme conditions ensures that industries can achieve both economic and environmental benefits.

Specific Applications of Silicon Carbide Tubes

Industrial Furnaces

Silicon Carbide Tubes play a crucial role in industrial furnaces. They maintain consistent temperatures, which is vital for processes like heat treatment and sintering. These tubes conduct heat efficiently, ensuring uniform temperature distribution within the furnace. This capability enhances the quality of the materials being processed.

Product Information:

- Silicon Carbide Tubes offer exceptional thermal conductivity.

- They withstand extreme temperatures and harsh conditions.

Compared to traditional materials, silicon carbide offers several advantages. Its durability and resistance to thermal shock reduce the risk of failure during rapid temperature changes. This reliability minimizes downtime and maintenance costs, making it a preferred choice for industries that demand high performance.

熱交換器

In heat exchangers, silicon carbide tubes enhance heat transfer efficiency. Their high thermal conductivity allows for effective energy exchange between fluids, optimizing the performance of the system. This efficiency is crucial in industries like power generation and chemical processing, where energy conservation is a priority.

Product Information:

- SiCチューブ provide high thermal conductivity and durability.

- They are ideal for aerospace, power generation, and chemical processing industries.

The use of silicon carbide tubes also leads to a reduction in maintenance needs. Their resistance to corrosion and chemical attack ensures a longer service life, reducing the frequency of replacements. This longevity translates into cost savings and improved operational efficiency.

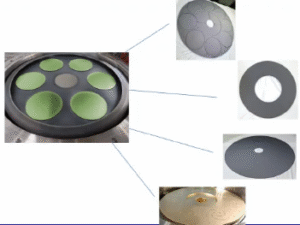

半導体製造

Silicon carbide tubes are indispensable in semiconductor manufacturing. They offer high-temperature stability, which is essential for processes that involve extreme heat. This stability ensures that the tubes maintain their structural integrity, supporting consistent production quality.

Product Information:

- Silicon Carbide Tubes resist temperatures up to 2500°C.

- They offer excellent temperature resistance and long service life.

Additionally, these tubes resist chemical exposure, a common challenge in semiconductor environments. Their chemical inertness prevents reactions with aggressive substances, ensuring reliability and reducing the risk of contamination. This resistance supports the production of high-quality semiconductor components.

Why Choose Ningbo VET Energy Technology Co. for Silicon Carbide Tubes

Quality Assurance

Commitment to High Standards

Ningbo VET Energy Technology Co.Ltd demonstrates a steadfast commitment to maintaining high standards in the production of Silicon Carbide Tubes. The company employs rigorous inspection and quality control practices throughout the manufacturing process. This dedication ensures that each tube meets the necessary criteria and performance standards, providing customers with reliable and high-quality products.

会社情報:

- Ningbo VET Energy Technology Co. focuses on high-end advanced materials.

- The company specializes in silicon carbide, graphite, and ceramics.

Certifications and Industry Recognition

The company’s adherence to quality is further validated by its certifications and industry recognition. Ningbo VET Energy Technology Co. has passed the ISO 9001:2015 international quality management system, underscoring its commitment to excellence. This certification assures customers of the company’s capability to consistently provide products that meet regulatory and customer requirements.

会社情報:

- ISO 9001:2015 certification highlights the company’s quality management.

- Industry recognition reflects the company’s reputation for excellence.

Innovation and Expertise

Cutting-Edge Technology in Production

Ningbo VET Energy Technology Co. leverages cutting-edge technology in the production of Silicon Carbide Tubes. The company invests in advanced manufacturing techniques to enhance product quality and performance. This focus on innovation allows the company to produce tubes that excel in high-temperature applications, offering superior thermal conductivity and durability.

会社情報:

- The company utilizes advanced manufacturing techniques.

- Innovation drives the production of high-performance silicon carbide tubes.

Experienced Team and Customer Support

The expertise of Ningbo VET Energy Technology Co.’s team plays a crucial role in its success. The company boasts a group of experienced and innovative industry talents, including R&D teams with rich practical experience in product design and engineering applications. This expertise ensures that customers receive not only top-quality products but also exceptional customer support.

会社情報:

- The company has a team of experienced industry professionals.

- R&D capabilities support product innovation and customer satisfaction.

Choosing Ningbo VET Energy Technology Co. for Silicon Carbide Tubes means partnering with a company that prioritizes quality, innovation, and customer satisfaction. Their commitment to high standards and cutting-edge technology ensures that customers receive products that meet the demands of high-temperature applications.

Comparing Silicon Carbide with Other Materials

Silicon Carbide vs. Alumina

Differences in Thermal Properties

Silicon carbide そして alumina both serve as essential materials in high-temperature applications, yet they exhibit distinct thermal properties. Silicon carbide boasts a thermal conductivity that is five times greater than that of alumina. This superior thermal conductivity allows silicon carbide to transfer heat more efficiently, making it ideal for applications requiring rapid heat dissipation. Additionally, silicon carbide’s low coefficient of thermal expansion ensures minimal dimensional changes under temperature fluctuations, enhancing its stability in high-temperature environments.

主なインサイト:

- Silicon carbide’s thermal conductivity surpasses that of alumina, making it more effective in heat transfer applications.

Cost and Application Considerations

When considering cost and application, alumina often presents a more economical option compared to silicon carbide. However, the choice between these materials depends on the specific requirements of the application. Silicon carbide, with its higher thermal conductivity and chemical stability, suits applications demanding extreme thermal conditions and chemical resistance. In contrast, alumina may suffice for less demanding environments where cost efficiency is a priority.

Application Tip:

- Choose silicon carbide for applications requiring high thermal performance and chemical resistance. Opt for alumina when budget constraints are a primary concern.

Silicon Carbide vs. Graphite

Comparative Analysis of Durability

Silicon carbide そして graphite differ significantly in terms of durability. Silicon carbide exhibits exceptional hardness, rated at 9.5 on the Mohs scale, which surpasses graphite’s softer nature. This hardness translates into superior wear resistance, making silicon carbide more durable in abrasive environments. Graphite, while softer, offers advantages in applications where lubrication and electrical conductivity are essential.

Durability Highlight:

- Silicon carbide’s hardness ensures greater durability compared to graphite, especially in abrasive conditions.

Suitability for Various Applications

The suitability of silicon carbide そして graphite varies based on application needs. Silicon carbide excels in high-temperature and chemically aggressive environments due to its thermal stability and chemical inertness. It is ideal for applications such as industrial furnaces and semiconductor manufacturing. Graphite, with its excellent electrical conductivity and lubricating properties, finds use in applications like electrodes and bearings.

Application Insight:

- Silicon carbide is preferred for high-temperature and chemically harsh environments. Graphite suits applications requiring electrical conductivity and lubrication.

Environmental Impact of Silicon Carbide Tubes

Sustainability

Eco-friendly Production Processes

Silicon carbide tubes contribute to sustainability through eco-friendly production processes. Manufacturers prioritize reducing environmental impact by implementing energy-efficient methods and minimizing waste. These processes ensure that the production of silicon carbide tubes aligns with sustainable practices, promoting a greener future.

科学的研究ファインディング:

- Silicon carbide tubes offer a fusion of durability and adaptability, enhancing their environmental benefits.

- Their production involves techniques that reduce energy consumption and emissions.

Recyclability and Waste Reduction

The recyclability of silicon carbide tubes plays a significant role in waste reduction. Industries can recycle these tubes at the end of their lifecycle, minimizing landfill contributions. This recyclability not only conserves resources but also supports circular economy principles, where materials are reused and repurposed.

科学的研究ファインディング:

- Silicon carbide’s mechanical strength and corrosion resistance contribute to its long lifespan, reducing the need for frequent replacements.

- The ability to recycle silicon carbide tubes enhances their economic and environmental benefits.

エネルギー効率

Contribution to Reducing Carbon Footprint

Silicon carbide tubes significantly contribute to reducing carbon footprints in industrial applications. Their superior thermal conductivity ensures efficient heat transfer, optimizing energy use. This efficiency leads to lower energy consumption, which directly reduces greenhouse gas emissions.

科学的研究ファインディング:

- Silicon carbide tubes’ exceptional thermal conductivity aids in energy efficiency, contributing to reduced carbon footprints.

- Their use in high-temperature operations like furnaces and heat exchangers maximizes energy utilization.

Long-term Environmental Benefits

The long-term environmental benefits of silicon carbide tubes extend beyond immediate energy savings. Their durability and resistance to harsh conditions mean fewer replacements, leading to less resource extraction and manufacturing. Over time, this durability translates into sustained environmental advantages, supporting industries in their efforts to operate sustainably.

科学的研究ファインディング:

- The durability and versatility of silicon carbide tubes ensure long-term environmental benefits.

- Their adaptability in various applications underscores their role in promoting sustainable industrial practices.

Silicon carbide tubes exemplify how advanced materials can align with environmental goals. Their sustainable production, recyclability, and energy efficiency make them a valuable asset in reducing environmental impact across industries.

Future Trends in Silicon Carbide Technology

Advancements in Material Science

Emerging Technologies and Innovations

Silicon carbide technology continues to evolve with groundbreaking advancements in material science. Researchers focus on enhancing the properties of silicon carbide to meet the demands of modern industries. 新興技術 such as additive manufacturing and nanotechnology play a pivotal role in these advancements. Additive manufacturing, also known as 3D printing, allows for the precise fabrication of complex silicon carbide structures, improving their performance in high-temperature applications. Nanotechnology, on the other hand, enables the development of silicon carbide composites with enhanced thermal and mechanical properties.

科学的研究ファインディング:

- Additive manufacturing enhances the precision and complexity of silicon carbide structures.

- Nanotechnology improves thermal and mechanical properties of silicon carbide composites.

Potential New Applications

The continuous innovation in silicon carbide technology opens doors to new applications across various sectors. Industries such as aerospace, automotive, and renewable energy explore the potential of silicon carbide for its superior thermal conductivity and durability. In aerospace, silicon carbide components can withstand extreme temperatures, making them ideal for use in jet engines and spacecraft. The automotive industry benefits from silicon carbide’s efficiency in electric vehicle power systems, where it enhances energy conversion and reduces heat loss. Renewable energy sectors, particularly solar and wind, utilize silicon carbide for its ability to improve energy efficiency and system reliability.

Application Insight:

- Aerospace and automotive industries leverage silicon carbide for its thermal resilience.

- Renewable energy sectors utilize silicon carbide to enhance energy efficiency.

Market Growth and Opportunities

Industry Demand and Expansion

The silicon carbide tube market experiences significant growth, driven by increasing demand across various industries. Projections indicate that this upward trend will continue from 2024 to 2031, highlighting the robust growth rates expected in the near future. Industries recognize the value of silicon carbide tubes for their exceptional properties, leading to widespread adoption in high-temperature applications. This demand fuels market expansion, creating opportunities for manufacturers to innovate and meet the evolving needs of their customers.

Market Insights:

- The silicon carbide tube market shows strong growth potential from 2024 to 2031.

- Increasing demand across industries drives market expansion.

Investment and Development Prospects

The promising growth of the silicon carbide market attracts significant investment and development prospects. Companies invest in research and development to enhance silicon carbide technology, aiming to improve product performance and reduce production costs. This investment fosters innovation, leading to the creation of advanced silicon carbide solutions that cater to diverse industrial applications. As the market expands, businesses have the opportunity to capitalize on the growing demand for silicon carbide products, positioning themselves as leaders in the field.

Investment Opportunities:

- Significant investment in R&D enhances silicon carbide technology.

- Market expansion offers opportunities for businesses to lead in silicon carbide solutions.

The future of silicon carbide technology looks promising, with advancements in material science and market growth paving the way for new applications and opportunities. As industries continue to seek innovative solutions for high-temperature applications, silicon carbide remains at the forefront, driving progress and shaping the future of technology.

Silicon carbide tubes stand out as essential components in high-temperature applications due to their exceptional properties. They offer superior heat transfer efficiency, corrosion resistance, and durability, making them invaluable in demanding industrial settings. Industries benefit from their ability to enhance heat treatment processes and ensure chemical inertness, leading to improved performance and longevity. Choosing quality products from Ningbo VET Energy Technology Co. ensures that businesses receive reliable and high-performance silicon carbide tubes, meeting the rigorous demands of modern industrial applications.

よくあるご質問

What are Silicon Carbide Tubes known for?

Silicon carbide tubes are renowned for their high-performance capabilities. They find extensive use in aerospace and defense sectors due to their ability to withstand extreme temperatures. These tubes also excel in high-temperature operations, making them a popular choice in various industrial applications.

How do Silicon Carbide Tubes enhance industrial efficiency?

Silicon carbide tubes improve industrial efficiency through their superior thermal conductivity. This property allows for efficient heat transfer, optimizing energy use in processes like power generation and chemical processing. As a result, industries experience reduced energy consumption and enhanced system performance.

Why are Silicon Carbide Tubes preferred in semiconductor manufacturing?

In 半導体製造, silicon carbide tubes offer high-temperature stability and chemical inertness. These properties ensure that the tubes maintain structural integrity during rapid temperature changes and resist chemical exposure. Consequently, they support consistent production quality and reliability.

What makes Silicon Carbide Tubes durable?

The durability of silicon carbide tubes stems from their exceptional mechanical strength and resistance to wear and abrasion. They withstand extreme conditions, including temperatures up to 2500°C, ensuring a long lifespan. This durability translates into cost-effectiveness, as industries benefit from reduced maintenance and replacement needs.

How do Silicon Carbide Tubes contribute to environmental sustainability?

Silicon carbide tubes contribute to environmental sustainability through their energy efficiency and recyclability. Their superior thermal conductivity optimizes energy use, reducing carbon emissions. Additionally, industries can recycle these tubes, minimizing waste and supporting circular economy principles.

What are the advantages of using Silicon Carbide Tubes in heat exchangers?

In heat exchangers, silicon carbide tubes enhance heat transfer efficiency due to their high thermal conductivity. This efficiency optimizes energy exchange between fluids, crucial for industries like power generation. Furthermore, their resistance to corrosion ensures a longer service life, reducing maintenance needs.

How does Ningbo VET Energy Technology Co. ensure the quality of Silicon Carbide Tubes?

Ningbo VET Energy Technology Co.Ltd ensures the quality of silicon carbide tubes through rigorous inspection and quality control practices. The company adheres to the ISO 9001:2015 international quality management system, guaranteeing products that meet regulatory and customer requirements.

What innovations are shaping the future of Silicon Carbide technology?

Emerging technologies such as additive manufacturing and nanotechnology are shaping the future of silicon carbide technology. Additive manufacturing allows precise fabrication of complex structures, while nanotechnology enhances thermal and mechanical properties. These innovations open doors to new applications across various sectors.

How does Silicon Carbide compare to other materials like Alumina and Graphite?

Silicon carbide surpasses alumina in thermal conductivity, making it more effective in heat transfer applications. Compared to graphite, silicon carbide offers greater durability due to its hardness. While alumina may be more economical, silicon carbide suits applications demanding extreme thermal conditions and chemical resistance.

What market opportunities exist for Silicon Carbide Tubes?

The silicon carbide tube market experiences significant growth, driven by increasing demand across industries. This trend creates opportunities for manufacturers to innovate and meet evolving customer needs. Investment in research and development enhances silicon carbide technology, positioning businesses as leaders in the field.