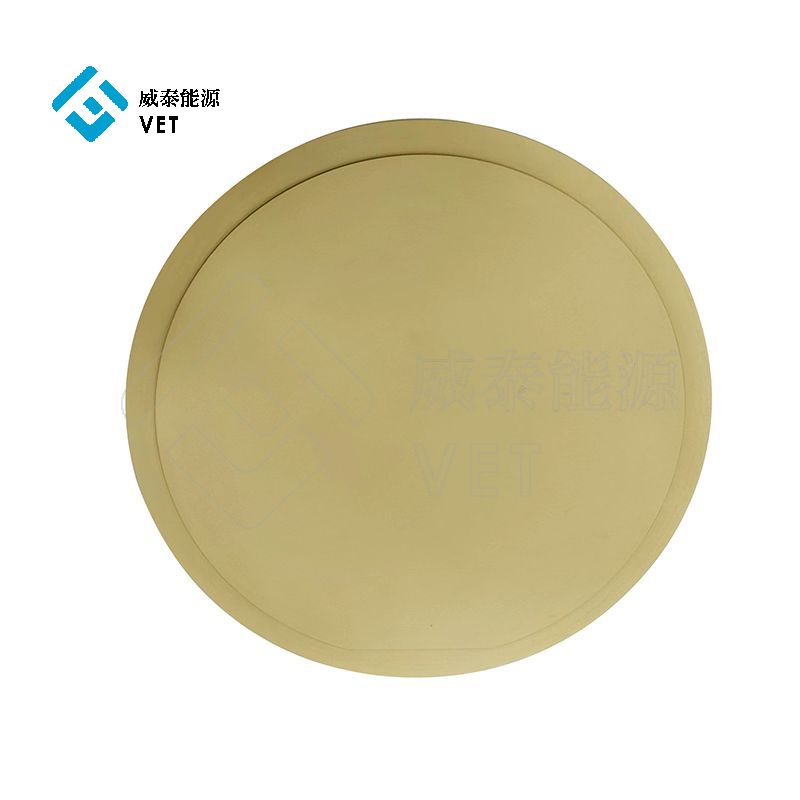

極端な熱管理を必要とする産業は、タックコーティングされたグラファイトスセプターの例外的な特性に依存します。 これらの部品は2000°を越える温度を耐えます 化学劣化に抵抗するC。 ザ・オブ・ザ・ CVDタックコーティング 耐久性を高め、均一性能を保障します。 お申し込み グラファイトのタックコーティング、製造業者は作ります優秀な熱安定性を達成します グラファイトの感受性 厳しい環境で欠かせません.

要点

- TaC-coatedグラファイトは2000°上の非常に高い熱を扱うことができます ツイート.

- について TaC層は錆を止めます 厳しい仕事のためにそれを大きいようにする化学害.

- これらの上塗を施してある部品 長く持続し、より少ない固定を必要として下さいお金および時間を節約して下さい.

TaCコーティングされたグラファイトスセプターのユニークな特性

2000°を超える熱安定性 ツイート

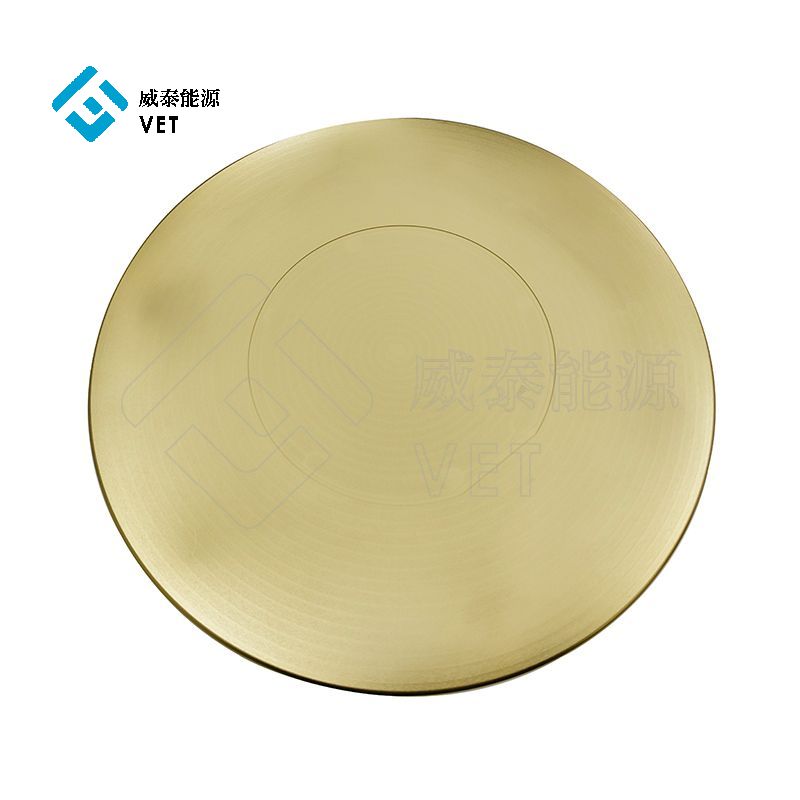

TaC-coatedグラファイトスセプター展示 例外的な熱安定性高温用途に最適です。 タンタルカーバイド(TaC)コーティングは2000°を超える温度に耐える保護バリアを提供します 構造の完全性を損なうことなくC。 半導体ウェーハ製造や航空宇宙部品製造など、極端な熱を必要とするプロセスで一貫した性能を保証します。 高温への長期暴露の下で分解できる光沢が無いグラファイトとは異なり、TaCコーティングは熱損傷を防ぎ、感受性の寿命を延ばします.

腐食および有害化学薬品への抵抗

化学的に積極的な環境で稼働する産業は、 耐食性 taC-coatedのグラファイトの感受性の。 TaC層は、酸化、化学浸食、反応性ガスからグラファイト基質を保護するシールドとして機能します。 このプロパティは、ハロゲン、酸、または他の腐食性物質を含むアプリケーションで特に価値があります。 コーティングは、過酷な化学物質への長期暴露の下でも、その完全性を維持し、信頼性の高い性能を確保し、敏感なプロセスにおける汚染の危険性を減らす.

耐久性および強いコーティングの付着

TaC-coatedのグラファイトの感受性の耐久性はTaCの層およびグラファイトの基質間の強い付着から茎を合わせます。 高度の化学蒸気の沈着(CVD)の技術は割れること、皮をむくことおよび摩耗に抵抗する均一および堅く結合されたコーティングを作成します。 この堅牢な接着により、スセプターの機械的強度を高め、繰り返し熱循環と機械的ストレスに耐えることができます。 その結果、業界は、故障の少ない経験とメンテナンスの要件を削減し、運用効率を改善しました.

TaCの利点は任意上のグラファイトのスセプターに塗りました

高温度環境における非凝固グラファイトの制限

比類のないグラファイトは、極端な熱で構造的な完全性を維持するのに苦労します。 2000°上の温度への延長された露出 Cは酸化および熱腐食を含む材料の分解に、頻繁に導きます。 これらの問題は、コンポーネントの性能と寿命を妥協します。 また、非コーティングされたグラファイトは、腐食性ガスや反応物質を関与する環境に適さない、化学反応に対する抵抗を欠いています。 頻繁な取り替えおよび失敗による光沢が無いグラファイトに頻繁に遭遇する企業はより高い維持費および操作不能に頼ります.

その他の高性能材料と比較してTACコーティングの利点

タックコーティングは、他の高性能材料を出力する特性のユニークな組み合わせを提供します。 セラミックスや耐火金属は熱抵抗を提供しながら、頻繁にTaCコーティンググラファイトの柔軟性と熱伝導性が欠けています。 ザ・オブ・ザ・ タックコーティングはグラファイトを増強します グラファイトの軽量・導電性を保ちながら、熱・化学的損傷に対して強固な障壁を発揮します。 半導体製造や航空宇宙工学など、耐久性と精度を問う用途に優れた性能を発揮します.

タックコーティングは、産業用途における共通の課題に対処する方法

タックコーティングは、高温産業プロセスで直面する共通の課題を効果的に解決します。 コーティングは酸化および化学分解を防ぎま、粗い環境の一貫した性能を保障します。 グラファイト基質への強い密着により、熱循環時の割れや剥離のリスクを最小限に抑えます。 サスペンサーの寿命を延ばし、メンテナンスニーズを削減することにより、TACコーティングされたグラファイトスセプターは、操業効率を高め、産業の長期コストを削減します.

高温度アプリケーションにおけるTACコーティンググラファイトスセプターの主な利点

高められた熱伝導性および均一熱配分

TaC-coatedのグラファイトの感受性 精密な熱管理を必要とする適用のExcel。 グラファイトの自然な熱伝導性および保護TaCのコーティングの組合せは有効な熱伝達を保障します。 このプロパティは、スセプターが表面全体に均一に熱を分配し、温度勾配を最小限に抑えることを可能にします。 均一な熱分布は、半導体ウェーハ製造などのプロセスにおいて極めて重要であり、マイナーな温度変化でも製品の品質を損なうことができます。 一貫した熱性能を維持することによって、これらの感受性はプロセス信頼性を高め、欠陥の可能性を減らします.

熱衝撃の抵抗による改善された効率

材料が急速な温度変化を経験するとき熱衝撃は、頻繁に割れるか、または構造的失敗に導きます。 TaC-coatedのグラファイトの感受性はコーティングおよび基質間の強い結束による熱衝撃への例外的な抵抗を示します。 この抵抗は、その完全性を損なうことなく、突然の温度変動を耐える感受性を可能にします。 機器の故障によるダウンタイムを削減し、高い運用効率を実現し、このプロパティから産業に利益をもたらします。 極端な熱循環に耐える能力は、これらの受容体が厳しい環境に不可欠です.

延長サービス寿命とメンテナンスコストの削減

TaC-coatedのグラファイトの感受性器の耐久性はより長い耐用年数に直接翻訳します。 ザ・オブ・ザ・ タックコーティングは保護します 酸化、化学腐食および機械的摩耗からのグラファイト基質は、頻繁な取り替えのための必要性をかなり減らします。 この延長寿命は維持費を下げ、操作上の混乱を最小限に抑えます。 これらの感受性に頼る企業は時間の上の費用効率を改善しました。 高品質のTACコーティングされたグラファイトスセプターに投資することで、メンテナンス予算を最適化しながら、企業は信頼できる性能を達成することができます.

TaC-coatedのグラファイトの感受性は高温環境で比類のない性能を提供します。 優れた熱安定性と耐薬品性は、精密・信頼性を必要とする業界に欠かせないものとなっています。 これらの受容体は、一貫した結果を保証する、非コーティングされたグラファイトおよび代替材料を外します。 この先端技術を採用することにより、業界は運用効率を高め、ダウンタイムを最小化し、コストを大幅に削減することができます.

よくあるご質問

タックコーティングされたグラファイトスセプターから最も有利な業界は?

半導体製造、航空宇宙、冶金などの産業は、優れた熱安定性、耐薬品性、極端な環境での耐久性のために、TaCコーティンググラファイトスセプターに大きく依存しています.

タックコーティングは、グラファイトスセプターの性能を向上させる方法は?

について TaCコーティング 熱安定性を高め、酸化を防ぎ、化学腐食に抵抗します。 この組合せは高温適用の信頼できる性能、延長寿命および減らされた維持を保障します.

TaC-coatedのグラファイトの感受性は長期に費用効果が大きいですか?

はい。 耐久性と長寿命は、交換頻度とメンテナンスコストを削減し、高性能材料を必要とする業界にコスト効率の高いソリューションを提供します.

製品の詳細については、下記までお問い合わせください。 steven@china-vet.com またはウェブサイト: www.vet-china.com.