タンタル炭化物(TaC)のコーティングの感受性の技術、進歩を含む tacのコーティングの感受性 高性能な業界では、システムが不可欠です。 卓越した熱安定性と耐摩耗性 タックコート 半導体および宇宙空間アプリケーションにおいて重要なコンポーネントを作る。 高度材料のための要求としてのような CVDタックコーティング 成長、革新のような tacのコーティングの回転感受性 製造工程の効率化と性能の向上を図っています.

要点

- タンタルカーバイド(TaC)コーティング 熱を扱い、長く持続するのを助けて下さい。 半導体や飛行機を作ることが大切です.

- コーティングを適用する新しい方法特別なガスやプラズマなど、TaCコーティングされた部品を強力にしやすくなります.

- 緑化法とリサイクルにより、製造中の環境への害が軽減されます.

タックコーティングスセプターの技術開発

タックコーティング技術におけるイノベーション

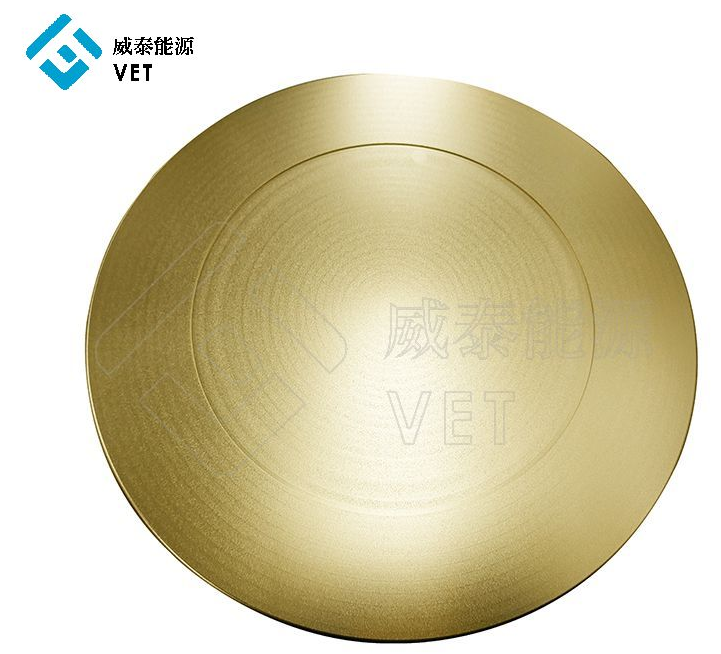

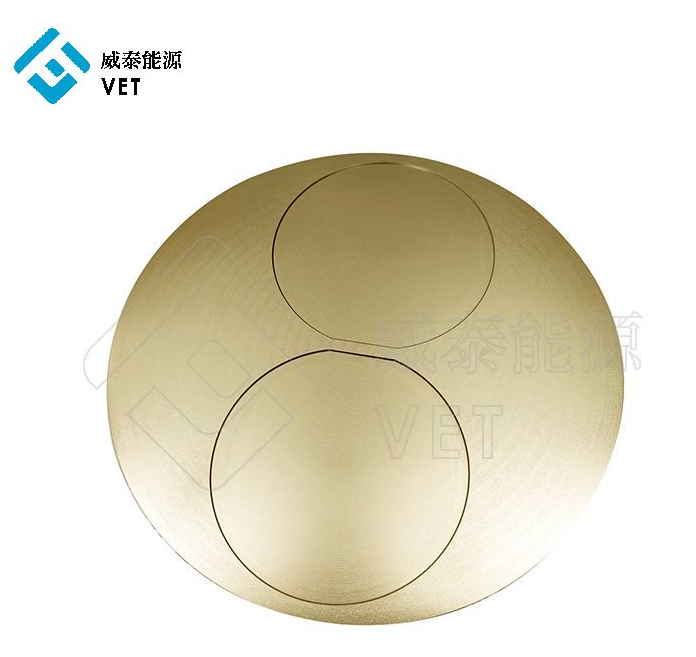

最近見られた年 タンタル炭化物のコーティング方法の重要な進歩. . 研究者は均一および欠陥なしのコーティングを達成するために高度の化学蒸気の沈殿物(CVD)の技術を開発しました。 これらの方法は、タックコーティングスセプターの熱的および機械的特性を高め、極端な環境でより信頼できます。 プラズマ強化蒸着プロセスは、コーティングの付着を改善し、生産時間を短縮する能力にも注目されています。 また、多層コーティングのようなイノベーションを探求し、特定の産業用途のパフォーマンスを最適化しています.

素材の耐久性と性能の改善

について タックコーティングの感受性材料の耐久性 物質科学の進歩により改善が進んでいます。 エンジニアは高温下で割れ、摩耗に抵抗するためにコーティングの微細構造の精製に焦点を合わせました。 タンタルカーバイドレイヤーとグラファイト基材の接合を強化し、これらのコンポーネントの寿命をさらに高めました。 これらの改良により、スセプターは、半導体や航空宇宙などの業界にとって重要な劣化のない繰り返し熱サイクルに耐えることができます.

高度な製造プロセスとの統合

現代的な製造プロセスのtacコーティングの感受性の技術の統合は生産を合理化しました。 オートメーションとロボティクスは、コーティングを精密と一貫性で適用する上で重要な役割を果たしています。 3Dプリンティングなどの添加剤製造技術は、これまで不可能だった複雑なスセプターデザインを作成するために使用されます。 廃棄物を削減するだけでなく、製造工程の全体的な効率を改善し、高機能材料の需要を増加させます.

TaCの上塗を施してあるグラファイトのスセプターのための市場の運転者

熱安定性および耐久性のための上昇の要求

業界は、極端な条件に耐えることができる材料を必要としています. TaC-coatedのグラファイトの感受性 優れた熱安定性と耐摩耗性を提供し、高性能な用途に不可欠です。 高温下での構造的完全性を維持する能力は、重要なプロセスの信頼性を保証します。 この需要は、航空宇宙や半導体などの分野から成り立ち、運用効率は耐久性のある材料に依存します。 会社は維持費を削減し、装置の寿命を拡張するためにこれらの受容器を優先します.

高温産業用途における成長

化学加工や金属加工などの高温環境は、高度な材料に依存します。 TaC-coatedのグラファイトの感受性は優秀な熱抵抗によるこれらの設定で包んでいます。 産業は極度な熱にさらされる炉、原子炉および他の装置でこれらの部品を使用します。 産業プロセスが進化するにつれて、高温に耐えることができる材料の必要性は成長し続けています。 この傾向は、さまざまな分野にわたってTaCコーティングされた感受性器の採用を促進します.

半導体への出資拡大 製造業

半導体業界は、現代の技術において重要な役割を果たしています。 製造業者はマイクロチップおよび電子部品のための成長した要求に応じる高度材料で重く投資します。 TaC上塗を施してあるグラファイトの感受性は必須です ウェーハ製造工程精密および熱安定性が重要である場合。 政府と民間企業は、世界の有意なリソースを割り当て、半導体製造を拡大します。 この投資は、高品質の受容体に対する要求を燃料化し、製造における一貫した性能を保証します.

主要産業への応用

半導体製造工程における役割

半導体製造は、精密・熱安定性に大きく対応しています。 TaC-coatedグラファイトの感受性はで重要な役割を担います ウェーハ製造工程. . これらのコンポーネントは、化学蒸気蒸着(CVD)およびエピタキシャル成長中に均一な熱分布を保証します。 極端な温度やレジスト摩耗に耐える能力は、半導体ウェーハの品質を向上させます。 メーカーは、これらの受容体に依存して、大量生産環境で一貫した性能を維持します。 より小さく、より効率的なマイクロチップの需要が高まるにつれて、これらの材料の重要性は上昇し続けています.

高温度部品のための大気空間の使用

航空宇宙産業は、高温および機械的ストレスに耐えることができる材料を必要とする極端な条件で頻繁に作動します。 タービンブレードやヒートシールドなどの重要なコンポーネントの生産において、TACコーティングされたグラファイトスセプターが使用されています。 異常な熱抵抗は失敗が選択ではない適用の信頼性を保障します。 エンジニアは急速な温度変化の間に構造の完全性を維持する能力のためのこれらの感受性器を評価します。 次世代航空宇宙技術の開発に欠かせないもの.

再生可能エネルギーと医療機器の活用

再生可能エネルギーおよび医療機器業界は、TACコートグラファイトスセプターの新しい用途を模索しています。 再生可能エネルギーでは、これらの材料がテストされています 高温燃料電池 そして太陽熱システム。 耐久性と耐熱性は、エネルギー変換プロセスの効率性を向上させます。 医学分野では、研究者は高度のイメージング機器および殺菌システムの可能性を調査しています。 これらの新興アプリケーションは、多岐にわたる業界におけるTaCコーティングされた感受性の多様性を強調しています.

持続可能性と環境への影響

環境に優しいコーティングプロセスの開発

産業の優先順位付け 環境に優しい方法 製造中の環境害を削減します。 有害化学物質の使用を最小限に抑えるコーティングプロセスを開発しています。 水系ソリューションと低排出化学蒸気蒸着(CVD)技術が牽引しています。 揮発性有機化合物(VOC)の発売を大気に下げる方法。 また、プラズマ強化堆積プロセスの進歩により、エネルギー消費量を削減し、より持続可能なものにします。 これらの革新を採用することにより、メーカーは環境の責任で高い性能を発揮することを目指しています.

グラファイトスセプターのリサイクルと再使用可能

グラファイトの感受性をリサイクルして下さい 廃棄物削減に重点を置いています。 エンジニアは、これらのコンポーネントの回復と再利用を可能にするシステムの設計です。 グラファイト基質を損なうことなく、熱洗浄や化学剥離などの技術が摩耗したコーティングを取り除きます。 このアプローチは、サスペンサのライフサイクルを拡張し、原材料抽出の必要性を減らします。 一部の企業は、閉鎖ループのリサイクルシステムを探索しています。また、使用したスセプターは、生産ラインに再生および再導入されています。 これらの取り組みは、資源の枯渇を最小限に抑え、循環経済に貢献します.

製造におけるカーボンフットプリントの低減

製造中の炭素排出量を削減する戦略を実装しています。 太陽光や風力などのエネルギー効率の高い機器や再生可能エネルギーの源を、製造施設に統合しています。 自動化・精密技術により、材料廃棄物を削減し、環境負荷を低減 一部の企業は、排出量を中和するためにカーボンオフセットプログラムを採用しています。 これらの取り組みは、グローバル・サステイナビリティの目標と一致し、業界のカーボンフットプリントを削減するためのコミットメントを示しています.

地域・グローバル市場動向

北米・欧州における成長トレンド

北米・欧州の採用を継続 新素材 高機能産業向け これらの領域は、製造技術を強化するために研究開発に大きく投資します。 米国における半導体分野は、国内生産を支える政府の取り組みによる大きな成長が見込まれています。 同様に、欧州諸国は航空宇宙の進歩に焦点を合わせ、TaCコーティンググラファイトスセプターのような材料の需要を運転します。 これらの地域の企業は品質と革新を優先し、グローバルな競争力を確保します。 確立された製造業者および研究所の強い存在は更に市場の成長を加速します.

アジア・太平洋における製造拡大

アジアパシフィックは、コストメリットと熟練した労働力で製造拠点として誕生しました。 中国、日本、韓国などの国々は、半導体および電子機器業界を支配します。 これらの国は、マイクロチップや他の電子部品の需要増加を満たすために、最先端の設備に投資しています。 また、堅牢なサプライチェーンにより、TACコーティングされたグラファイトスセプターの効率的な生産が可能になります。 アジア・パシフィックの政府は、有利な政策とインフラ開発を通じて、産業成長を積極的に支援しています。 この拡張は、地域をグローバル市場で重要なプレーヤーとして位置付けます.

ラテンアメリカと中東で市場と機会を新興

ラテンアメリカと中東は、TaCコーティングされたグラファイトスセプター市場のための未適用の機会を提示しました。 これらの地域は、産業化とインフラ開発を成長させています。 ラテンアメリカでは、ブラジルやメキシコなどの国々が再生可能エネルギーや航空宇宙分野に投資し、先進材料の需要を創出しています。 中東は、ハイテク産業における重要な投資で、経済の多様化に注力しています。 これらの新興市場は、メーカーのプレゼンスを拡大し、新しいアプリケーションに参入する可能性があります。 戦略的パートナーシップとローカライズされた生産は、企業がこれらの機会を調達するのに役立ちます.

製品の詳細については、下記までお問い合わせください。 steven@china-vet.com またはウェブサイト: www.vet-china.com.