TaC 코팅 링 are transforming crystal growth in LED manufacturing by tackling challenges related to purity and efficiency. With their exceptional properties, such as resistance to extreme temperatures and chemical inertness, they drastically minimize contamination risks. For example, SiC wafers grown in traditional graphite crucibles show a carrier concentration of 4.5×10^17/cm, whereas those produced in crucibles with TAC COATING achieve an improved concentration of 7.6×10^15/cm. This advancement leads to cleaner crystals, higher production yields, and more cost-effective processes. Additionally, the application of CVD TAC COATING · CVD SIC COATING technologies further enhances the durability and stability of these rings, solidifying their role as essential components in modern LED production.

키 테이크아웃

- TaC 코팅 링 keep crystals clean by stopping contamination. This improves how LEDs work with light and electricity.

- Using TaC Coated Rings makes more good products by reducing flaws. This saves money and makes production faster.

- TaC Coated Rings last a long time and can be reused. This helps the environment and cuts down on waste in LED making.

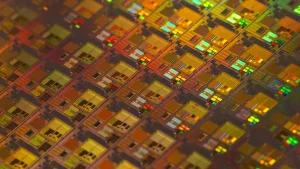

Crystal Growth in LED Manufacturing

Importance of High-Purity Crystals

High-purity crystals form the backbone of LED manufacturing. Their quality directly impacts the performance, efficiency, and lifespan of LED devices. Crystals with fewer impurities exhibit superior electrical and optical properties, which are essential for producing high-brightness LEDs. Manufacturers prioritize purity to ensure consistent light output and color accuracy, critical for applications like displays and lighting systems. High-purity gallium nitride (GaN) materials, for instance, enhance crystallinity and reduce defects, leading to better device reliability. The use of advanced materials, such as TaC Coated Rings, plays a pivotal role in maintaining this purity during the crystal growth process.

Challenges in Achieving Purity and Yield

Achieving high-purity crystals and optimal yield in LED manufacturing presents several challenges. Traditional methods, such as metal-organic chemical vapor deposition (MOCVD), often struggle with defect reduction and uniformity in GaN crystallization. These imperfections can compromise long-term efficiency and display performance. Additionally, precision in wafer cutting, chip transfer, alignment, and packaging is critical. Even minor errors during these stages can introduce defects, lowering yield and affecting overall quality. Manufacturers must also address contamination risks during crystal growth, which can degrade material purity. Innovations like TaC Coated Rings help mitigate these issues by preventing contamination and enhancing process stability, ultimately improving yield and reducing production costs.

The Role of TaC Coated Rings

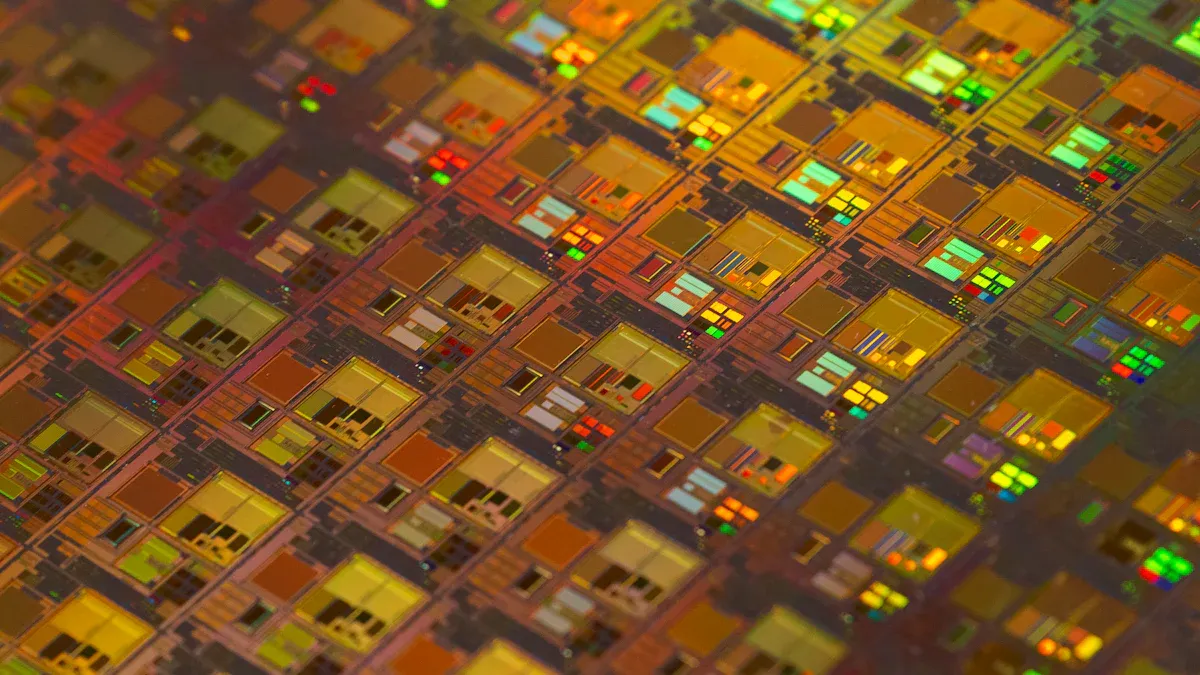

Material Properties of TaC Coated Rings

TaC 코팅 링 exhibit exceptional material properties that make them indispensable in crystal growth processes. Their high thermal stability ensures reliable performance under extreme temperatures, often exceeding 500 °C. The tantalum coating reacts with carbon at these temperatures to form tantalum carbide (TaC), which prevents carbon loss and enhances durability. This unique property allows TaC coated rings to outperform other coating materials in high-temperature applications.

The chemical vapor deposition (CVD) method used to prepare TaC coatings ensures uniform thickness and high purity. These coatings also possess a low thermal expansion coefficient of 6.6×10−6 K−1, reducing the risk of cracking during thermal cycling. Compared to other materials, TaC coatings offer superior mechanical stability and density, making them ideal for maintaining the integrity of the crystal growth environment.

| 제품정보 | TaC 코팅 | Other Coating Materials |

|---|---|---|

| Thermal Expansion Coefficient | 6.6×10−6 K−1 | Varies (e.g., graphite, C/C) |

| 준비 방법 | CVD (Chemical Vapor Deposition) | Various methods |

| 기계 안정성 | High-temperature stability | Varies |

| Purity | High purity | Varies |

| 제품정보 | High density | Varies |

| Thickness Control | Uniform thickness | Varies |

뚱 베어: TaC coatings are particularly advantageous for SiC crystal growth due to their high density and ability to minimize defects during preparation.

Contamination Prevention in Crystal Growth

Contamination poses a significant challenge in crystal growth, as impurities like carbon, oxygen, and nitrogen can degrade the quality of the crystals. TaC coated rings act as a barrier against these contaminants, ensuring cleaner crystals with fewer defects. Studies have shown that TaC coated graphite materials used in the thermal field for SiC and AlN preparation significantly reduce impurities, resulting in improved resistivity and minimized edge defects.

By preventing contamination, TaC coated rings enhance the purity of single crystals, which is critical for LED manufacturing. Cleaner crystals lead to better electrical and optical properties, directly impacting the performance and reliability of LED devices. Manufacturers benefit from reduced defect rates and higher yields, making TaC coated rings a cost-effective solution for maintaining crystal integrity.

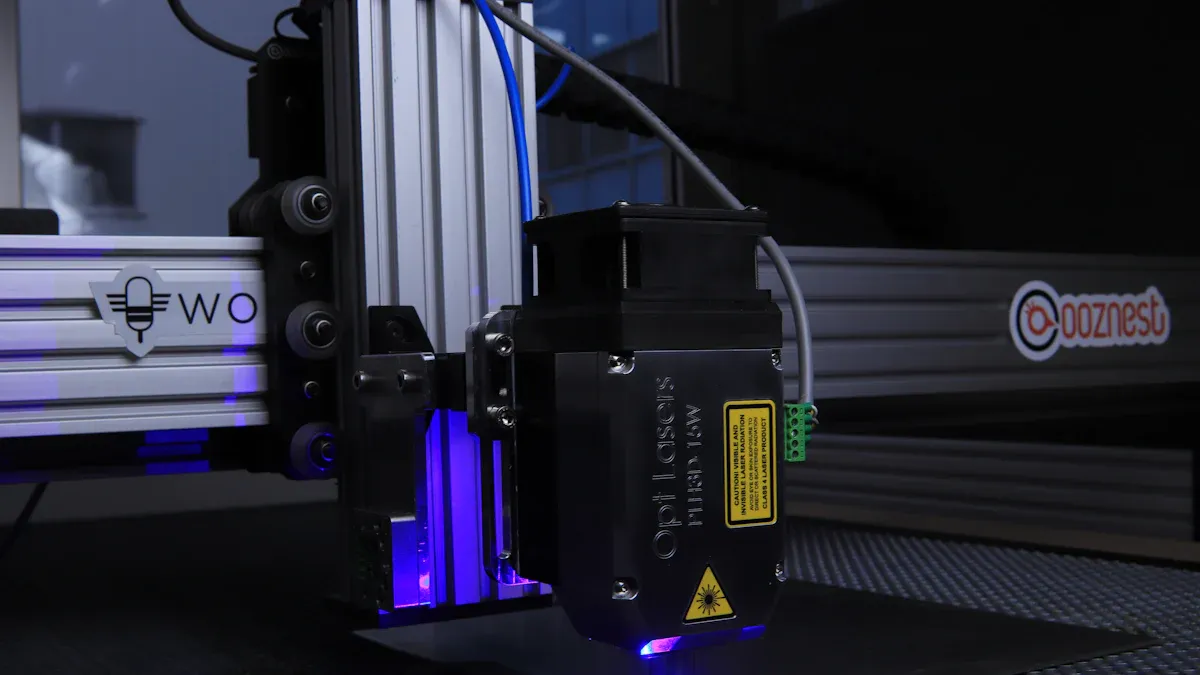

Enhancing Stability and Efficiency

TaC coated rings contribute to the stability and efficiency of the crystal growth process. Their high-temperature resistance ensures consistent performance over multiple cycles, with negligible weight loss and no damage observed after extensive use. This durability allows manufacturers to reuse TaC coated crucibles, reducing material costs and improving sustainability.

The uniformity of TaC coatings, achieved through the CVD method, ensures precise control over the crystal growth environment. This stability minimizes fluctuations in temperature and pressure, leading to more consistent crystal formation. Additionally, the high density and purity of TaC coatings reduce the likelihood of defects, further enhancing the efficiency of the process.

Manufacturers rely on TaC coated rings to optimize crystal growth, improve yield, and reduce production costs. Their ability to maintain stability under extreme conditions makes them a cornerstone of modern LED manufacturing.

TaC 코팅 반지의 이점

Improved Purity and Reduced Contamination

TaC Coated Rings significantly enhance the purity of crystals by acting as a robust barrier against contaminants. During the crystal growth process, impurities such as carbon, oxygen, and nitrogen can infiltrate the environment, degrading the quality of the final product. The unique properties of these rings, including their chemical inertness and high thermal stability, prevent such contamination. This ensures that the crystals maintain their structural integrity and exhibit superior optical and electrical properties.

Manufacturers have observed a marked reduction in defect rates when using TaC Coated Rings. For instance, studies show that these rings minimize edge defects and improve resistivity in materials like silicon carbide (SiC) and aluminum nitride (AlN). This improvement directly translates to higher-quality LEDs with better performance and reliability. By maintaining a cleaner growth environment, these rings not only enhance purity but also reduce the need for additional purification steps, saving time and resources.

* 이름: Cleaner crystals lead to LEDs with consistent brightness and color accuracy, which are critical for high-performance applications.

Higher Yield and Cost-Effectiveness

The use of TaC Coated Rings in LED manufacturing has a direct impact on production yield. By reducing contamination and defects, these rings enable manufacturers to produce more usable crystals per batch. This improvement in yield lowers the overall cost of production, making the manufacturing process more economical.

Additionally, the high durability of TaC Coated Rings allows them to withstand multiple production cycles without significant wear or degradation. This reduces the frequency of replacements, further cutting down operational costs. The uniformity of the coatings, achieved through advanced chemical vapor deposition (CVD) techniques, ensures consistent performance across batches. This consistency is crucial for maintaining high production standards and meeting industry demands.

Manufacturers also benefit from the reduced downtime associated with equipment maintenance. The long-lasting nature of these rings minimizes interruptions, allowing for smoother and more efficient operations. This combination of higher yield and cost-effectiveness makes TaC Coated Rings an invaluable asset in the competitive LED manufacturing industry.

Long-Term Durability in LED Manufacturing

Durability is a key factor in the selection of materials for LED manufacturing, and TaC Coated Rings excel in this regard. Their ability to withstand extreme temperatures and harsh chemical environments ensures reliable performance over extended periods. Unlike other materials that may degrade or lose effectiveness after repeated use, these rings maintain their structural and functional integrity.

The high thermal stability of TaC Coated Rings prevents cracking or deformation during thermal cycling, a common challenge in crystal growth processes. This stability not only extends the lifespan of the rings but also contributes to the overall reliability of the manufacturing equipment. Manufacturers can rely on these rings to deliver consistent results, even under demanding conditions.

뚱 베어: Investing in durable components like TaC Coated Rings reduces long-term costs and enhances the sustainability of LED production.

The long-term durability of these rings also aligns with the industry’s push toward more sustainable practices. By reducing waste and the need for frequent replacements, they contribute to a more environmentally friendly manufacturing process. This durability, combined with their other benefits, underscores the critical role of TaC Coated Rings in modern LED manufacturing.

TaC Coated Rings have revolutionized crystal growth in LED manufacturing by enhancing purity, yield, and efficiency. Their ability to prevent contamination and improve stability ensures superior crystal quality. These rings offer a cost-effective solution for manufacturers aiming to optimize production. Adopting this technology can lead to better-performing LEDs and more sustainable manufacturing practices.

제품 정보

What makes TaC Coated Rings superior to other materials in LED manufacturing?

TaC 코팅 링 excel due to their high thermal stability, chemical inertness, and durability. These properties ensure cleaner crystals, reduced defects, and enhanced production efficiency.

뚱 베어: Their ability to withstand extreme conditions makes them ideal for high-precision applications like LED manufacturing.

How do TaC Coated Rings improve production yield?

By minimizing contamination and defects, TaC Coated Rings increase the number of usable crystals per batch. This improvement directly reduces production costs and enhances overall efficiency.

Are TaC Coated Rings environmentally sustainable?

Yes, their long-term durability reduces waste and the need for frequent replacements. This aligns with sustainable manufacturing practices and supports eco-friendly production goals.

* 이름: Investing in durable materials like TaC Coated Rings promotes both cost savings and environmental responsibility.