TaC coated graphite susceptors deliver exceptional performance in epitaxial growth processes. Their superior thermal stability and chemical resistance ensure consistent results in high-temperature environments. Ningbo VET Energy Technology Co. specializes in advanced solutions, including the TaC coating rotation susceptor, SiC coated graphite susceptor, and CVD SiC coating susceptor, driving progress in semiconductor manufacturing with precision-engineered materials. Additionally, our SiC coating graphite wafer susceptors are designed to meet the demanding requirements of modern applications.

Key Takeaways

- TaC coated graphite parts stay stable in very high heat. They work well at over 2,200°C, which is important for making advanced semiconductors.

- TaC coatings resist chemicals, stopping bad reactions during crystal growth. This keeps crystals pure and lowers costs by needing fewer replacements.

- TaC coated graphite spreads heat evenly, making better crystals. This reduces flaws and improves devices like LEDs and RF tools.

Understanding TaC Coated Graphite Susceptors

What Are TaC Coated Graphite Susceptors?

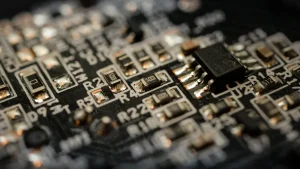

TaC coated graphite susceptors are advanced materials designed to enhance the efficiency and precision of epitaxial growth processes. These susceptors consist of a graphite base coated with tantalum carbide (TaC), a compound known for its exceptional thermal and chemical stability. The TaC coating acts as a protective layer, enabling the susceptor to withstand extreme temperatures and corrosive environments without degrading. This durability makes them indispensable in semiconductor manufacturing, where consistent performance is critical.

The semiconductor industry’s rapid growth and the increasing miniaturization of electronic components have amplified the demand for TaC coated graphite susceptors. Their ability to support higher energy efficiency further underscores their importance in modern applications.

Key attributes of TaC coated graphite susceptors include:

- Thermal Stability: They maintain structural integrity at high temperatures, ensuring reliable performance during demanding processes.

- Chemical Resistance: The TaC coating prevents reactions with corrosive chemicals, extending the lifespan of the susceptor.

- Uniformity: Their precise construction promotes consistent heat distribution, which is vital for achieving high-quality crystal growth.

Role in Epitaxial Growth Processes

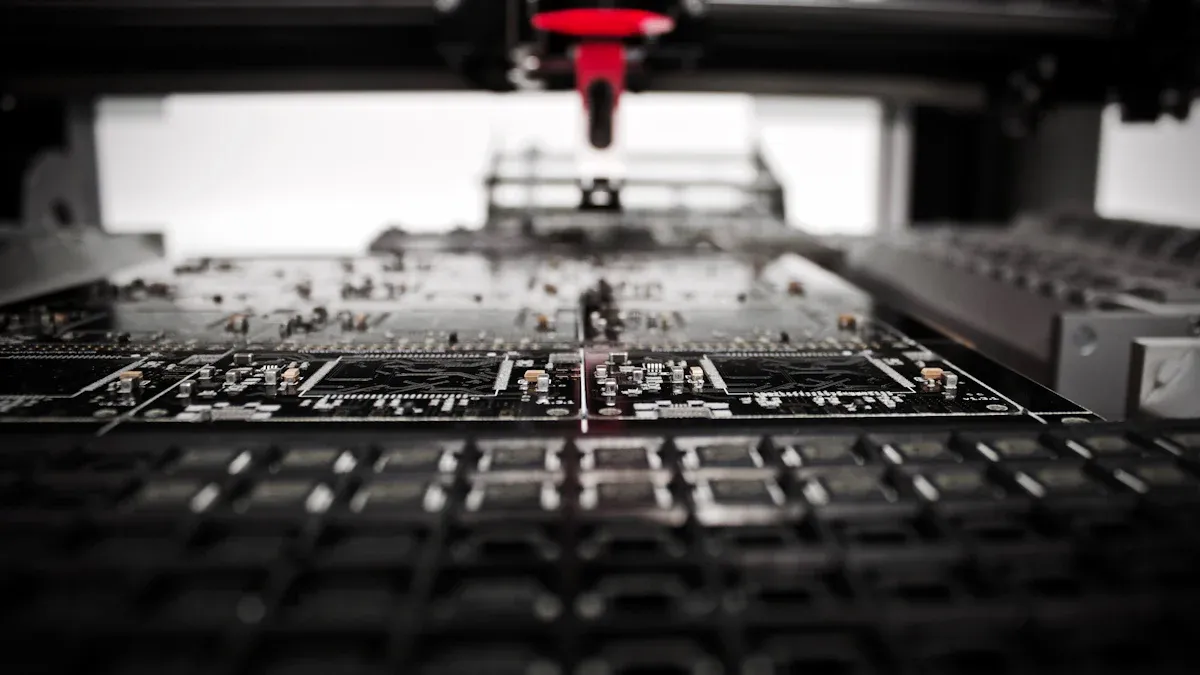

TaC coated graphite susceptors play a pivotal role in epitaxial growth processes by providing a stable and controlled environment for crystal formation. These processes involve depositing thin layers of material onto a substrate to create high-quality crystals used in semiconductors, LEDs, and RF devices. The unique properties of TaC coated graphite susceptors ensure optimal conditions for these delicate operations.

| Improvement | Description |

|---|---|

| Cleaner Products | Minimal carbon, oxygen, nitrogen, and other impurities observed in SiC and AlN preparations. |

| Fewer Edge Defects | Reduced edge defects leading to better crystal quality. |

| Lower Resistivity | Enhanced electrical properties in each region. |

| Reduced Micropores | Significant decrease in micropores and etching pits after KOH etching. |

| Weight Loss | Almost zero weight loss of TaC crucible, maintaining a non-destructive appearance. |

| Recyclability | Lifespan of up to 200 hours, enhancing sustainability. |

These susceptors also demonstrate excellent compatibility with advanced epitaxial techniques, such as metal-organic chemical vapor deposition (MOCVD). Their ability to minimize impurities like titanium, boron, and aluminum ensures cleaner crystal growth. Additionally, samples grown using TaC coated graphite susceptors exhibit higher carrier lifetimes, which are further improved when combined with chlorine-based precursors.

By reducing defects and enhancing uniformity, TaC coated graphite susceptors contribute to the production of superior semiconductor devices. Their extended service life and recyclability make them a sustainable choice for manufacturers.

Key Advantages of TaC Coated Graphite Susceptors

Thermal Stability for High-Temperature Applications

TaC coated graphite susceptors excel in high-temperature environments, making them indispensable for processes like epitaxy and chemical vapor deposition (CVD). Their ability to maintain structural integrity at extreme temperatures ensures consistent performance during demanding applications. These susceptors are designed to operate above 1,600°C, a critical requirement for SiC wafer production. Furthermore, they remain stable at temperatures exceeding 3,000°C, a feature that has also proven valuable in aerospace applications such as rocket nozzles.

The exceptional thermal conductivity of these materials plays a pivotal role in efficient heat management. This property ensures uniform temperature distribution across the susceptor, reducing the risk of thermal stress and enhancing the quality of crystal growth. Their high purity further minimizes contamination, which is essential for maintaining the stringent standards of semiconductor manufacturing.

- Key Highlights:

- Operates reliably at temperatures above 1,600°C.

- Maintains stability even beyond 3,000°C.

- Ensures efficient heat management through superior thermal conductivity.

The unmatched thermal stability of TaC coated graphite susceptors makes them a cornerstone of high-temperature applications, ensuring reliability and precision in every process.

Chemical Resistance in Corrosive Environments

The chemical resistance of TaC coated graphite susceptors sets them apart from traditional materials. The tantalum carbide coating acts as a robust barrier, protecting the graphite core from corrosive chemicals commonly used in epitaxial growth processes. This resistance significantly extends the lifespan of the susceptor, reducing the need for frequent replacements and lowering operational costs.

In addition to durability, the chemical inertness of the TaC coating ensures that no unwanted reactions occur during crystal growth. This feature is particularly important in processes like metal-organic chemical vapor deposition (MOCVD), where even trace impurities can compromise the quality of the final product. By preventing contamination, these susceptors contribute to the production of cleaner and more reliable semiconductor devices.

- Advantages of Chemical Resistance:

- Protects against corrosive chemicals, enhancing durability.

- Prevents unwanted reactions, ensuring high-purity crystal growth.

- Reduces operational costs by minimizing replacements.

The chemical resistance of TaC coated graphite susceptors ensures long-term reliability, making them a cost-effective and high-performance choice for manufacturers.

Uniformity for Improved Crystal Quality

Uniformity is a critical factor in achieving high-quality crystal growth, and TaC coated graphite susceptors deliver exceptional results in this area. Their precise construction ensures consistent heat distribution, which is vital for maintaining uniform growth conditions across the substrate. This uniformity reduces the occurrence of defects, such as micropores and etching pits, leading to superior crystal quality.

The high purity of these susceptors further enhances their performance by minimizing impurities like titanium, boron, and aluminum. This results in cleaner crystal growth and higher carrier lifetimes, which are essential for advanced semiconductor applications. Additionally, their recyclability and extended service life make them a sustainable option for manufacturers.

- Key Benefits of Uniformity:

- Promotes consistent heat distribution for uniform crystal growth.

- Reduces defects, improving overall crystal quality.

- Enhances sustainability through recyclability and long service life.

By ensuring uniformity and reducing defects, TaC coated graphite susceptors enable the production of high-performance semiconductor devices, meeting the demands of modern technology.

Why TaC Coated Graphite Susceptors Outperform Traditional Materials

Limitations of Traditional Graphite Susceptors

Traditional graphite susceptors face significant challenges in high-temperature and corrosive environments. Their structural integrity diminishes at elevated temperatures, often leading to degradation around 2,000°C. This limitation restricts their use in advanced epitaxial growth processes. Additionally, bare graphite lacks sufficient chemical resistance, making it vulnerable to corrosive gases like ammonia (NH₃) used in semiconductor manufacturing. Impurities such as oxygen, which can reach up to 260 ppm, further compromise the quality of crystal growth.

Thermal shock resistance is another drawback. Bare graphite struggles to withstand rapid temperature changes, leading to cracking and reduced lifespan. These limitations hinder the efficiency and reliability of traditional materials in demanding applications.

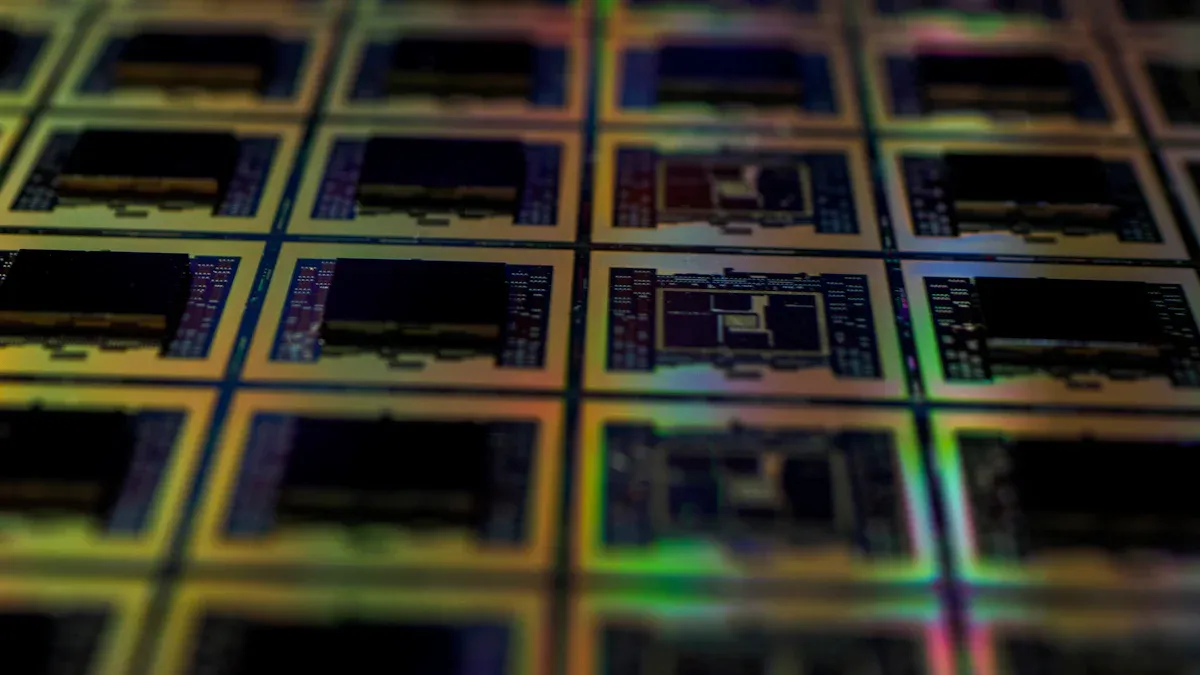

| Property | TaC Coating | SiC Coating | Bare Graphite |

|---|---|---|---|

| Max Temperature | >2200°C | <1600°C | ~2000°C (with degradation) |

| Etch Rate in NH₃ | 0.2 µm/hr | 1.5 µm/hr | N/A |

| Impurity Levels | <5 ppm | Higher | 260 ppm oxygen |

| Thermal Shock Resistance | Excellent | Moderate | Poor |

How TaC Coating Resolves Common Challenges

TaC coated graphite susceptors address these challenges with their superior material properties. The tantalum carbide coating enhances thermal stability, allowing the susceptor to operate reliably at temperatures exceeding 2,200°C. This capability ensures consistent performance in high-temperature epitaxial growth processes. The TaC coating also provides exceptional chemical resistance, reducing the etch rate in NH₃ to just 0.2 µm/hr compared to 1.5 µm/hr for SiC coatings.

The coating’s low impurity levels, under 5 ppm, minimize contamination during crystal growth. This purity results in cleaner crystals with fewer defects. Furthermore, TaC coated graphite susceptors exhibit excellent thermal shock resistance, enabling them to endure rapid temperature fluctuations without cracking. These improvements make them a reliable choice for semiconductor manufacturing.

- Additional performance benefits include:

- Up to 14% reduction in friction for TaC-coated components.

- Estimated fuel savings of 0.6% to 1% in related applications.

- Enhanced durability during compression and combustion cycles.

Long-Term Benefits for Semiconductor Manufacturing

The long-term benefits of TaC coated graphite susceptors extend beyond immediate performance improvements. Their durability reduces the frequency of replacements, lowering operational costs. The extended lifespan, combined with recyclability, supports sustainable manufacturing practices. By minimizing impurities and defects, these susceptors improve the quality of semiconductor devices, enhancing their reliability and efficiency.

Manufacturers benefit from the ability to produce high-performance devices with fewer defects and higher carrier lifetimes. This advantage positions TaC coated graphite susceptors as a cornerstone of modern semiconductor production, meeting the industry’s growing demands for precision and sustainability.

Real-World Applications of TaC Coated Graphite Susceptors

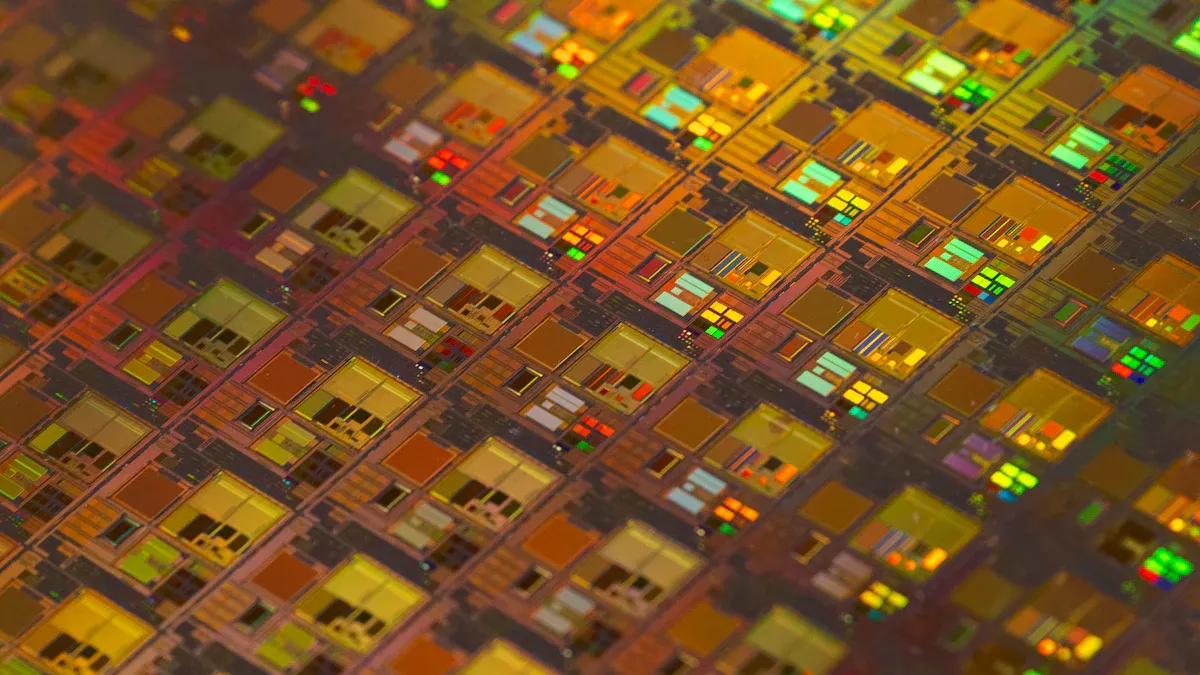

Enhancing SiC and AlN Crystal Growth

TaC coated graphite susceptors have become essential in the production of silicon carbide (SiC) and aluminum nitride (AlN) crystals. These materials are critical for high-power and high-frequency electronic devices. The exceptional thermal stability and chemical resistance of these susceptors create an ideal environment for crystal growth. They minimize impurities and defects, ensuring superior crystal quality. Their ability to withstand extreme temperatures and corrosive environments makes them indispensable for advanced epitaxial growth processes.

Applications in High-Performance LEDs and RF Devices

The demand for high-performance LEDs and radio frequency (RF) devices has surged in recent years. TaC coated graphite susceptors play a pivotal role in manufacturing these components. Their uniform heat distribution ensures consistent epitaxial layer deposition, which is crucial for achieving optimal device performance. By reducing defects and enhancing material purity, these susceptors contribute to the production of LEDs with higher brightness and RF devices with improved signal integrity.

Contributions by Ningbo VET Energy Technology Co.

Ningbo VET Energy Technology Co. has established itself as a leader in the development of TaC coated graphite susceptors. The company’s precision-engineered products meet the rigorous demands of semiconductor manufacturing. Their solutions enhance the efficiency and reliability of epitaxial growth processes, enabling manufacturers to produce cutting-edge devices. By prioritizing innovation and quality, Ningbo VET Energy Technology Co. continues to drive advancements in the industry.

TaC coated graphite susceptors have redefined epitaxial growth processes with their unmatched performance and reliability.

- Key Benefits:

- Superior thermal stability and chemical resistance.

- Enhanced crystal quality and manufacturing efficiency.

Ningbo VET Energy Technology Co. leads the industry by delivering innovative solutions that empower semiconductor manufacturers to meet modern technological demands.

FAQ

What makes TaC coated graphite susceptors superior to traditional materials?

TaC coated graphite susceptors offer unmatched thermal stability, chemical resistance, and uniformity. These properties ensure better performance, longer lifespan, and higher-quality crystal growth in semiconductor manufacturing.

How do TaC coated graphite susceptors improve sustainability?

Their extended lifespan and recyclability reduce waste and operational costs. These features make them an environmentally friendly choice for modern semiconductor manufacturing processes.

Can TaC coated graphite susceptors handle extreme temperatures?

Yes, they operate reliably at temperatures exceeding 2,200°C. Their thermal stability ensures consistent performance in high-temperature applications like epitaxial growth and chemical vapor deposition.

Tip: For optimal results, always source TaC coated graphite susceptors from trusted manufacturers like Ningbo VET Energy Technology Co. 🏆