Wafer Robotic Arms represent a pinnacle of technological advancement in semiconductor manufacturing. These sophisticated machines utilize cutting-edge technology to handle wafers with unparalleled precision and efficiency. Precision ensures that each wafer is processed accurately, minimizing errors and maximizing yield. Efficiency in wafer handling reduces production time and costs, enhancing overall productivity. The integration of AI and IoT further elevates these systems, enabling real-time data analysis and adaptive control. This synergy of technology not only optimizes performance but also sets new standards in the industry.

Key Takeaways

- Wafer robotic arms enhance semiconductor manufacturing by ensuring precision and efficiency, which are critical for high-quality production.

- The evolution of these robotic arms has been driven by advancements in AI and machine learning, allowing them to adapt and optimize operations in real-time.

- Automation through wafer robotic arms reduces human error and accelerates production cycles, leading to significant cost savings for manufacturers.

- Advanced sensor technologies enable precise positioning and monitoring of cleanroom conditions, ensuring wafers are handled safely and remain uncontaminated.

- The integration of Industry 4.0 and IoT technologies facilitates better connectivity and data exchange, optimizing manufacturing processes and increasing productivity.

- Future trends indicate a focus on sustainability and the continued integration of AI, promising to enhance the capabilities and efficiency of wafer robotic arms.

- Investments in research and development are crucial for manufacturers to innovate and meet the growing demands of the semiconductor industry.

Overview of Wafer Robotic Arms Technology

Evolution of Wafer Handling Robots

Wafer handling robots have undergone significant transformation since their inception. Initially, these machines performed basic tasks with limited precision. Early models relied on simple mechanical systems to move wafers from one point to another. Over time, advancements in technology introduced more sophisticated designs. Engineers incorporated advanced sensors and control systems, enhancing the robots’ ability to handle wafers with greater accuracy.

The integration of artificial intelligence marked a pivotal moment in the evolution of wafer robotic arms. AI algorithms enabled these machines to learn and adapt to various tasks, improving their efficiency and reliability. Machine learning further refined their capabilities, allowing them to predict and respond to potential issues before they occurred. This evolution has positioned wafer robotic arms as essential tools in modern semiconductor manufacturing.

Importance in Semiconductor Manufacturing

In semiconductor manufacturing, precision and efficiency are paramount. Wafer robotic arms play a crucial role in achieving these objectives. They ensure that each wafer is handled with care, minimizing the risk of damage or contamination. This precision is vital in maintaining the quality of semiconductor products.

Efficiency in wafer handling directly impacts production timelines and costs. Wafer robotic arms streamline the manufacturing process by automating repetitive tasks. This automation reduces human error and increases throughput, leading to faster production cycles. As a result, manufacturers can meet the growing demand for semiconductors more effectively.

Moreover, wafer robotic arms contribute to maintaining cleanroom standards. Their design minimizes the introduction of contaminants, ensuring that wafers remain pristine throughout the manufacturing process. This capability is essential in producing high-quality semiconductor devices.

Key Technological Components and Innovations

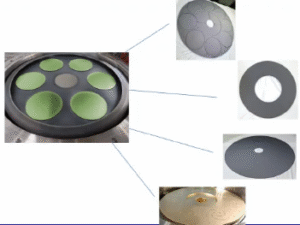

Mechanical Design and Engineering

Mechanical design forms the backbone of wafer robotic arms. Engineers focus on creating robust structures that can withstand the demands of semiconductor manufacturing. They use high-quality materials to ensure durability and reliability. The design often incorporates modular components, allowing for easy maintenance and upgrades. This modularity enhances the flexibility of the robotic arms, enabling them to adapt to various manufacturing processes.

Precision engineering plays a crucial role in the mechanical design. Engineers meticulously calibrate each component to achieve optimal performance. They employ advanced techniques to minimize vibrations and ensure smooth operation. This attention to detail results in wafer robotic arms that can handle delicate wafers with exceptional accuracy.

Sensor Technologies

Sensor technologies elevate the capabilities of wafer robotic arms. These sensors provide critical data that guides the robots’ movements and actions. Engineers integrate machine vision systems to enable precise positioning and alignment. These systems use cameras and image processing algorithms to detect and correct any deviations in real-time.

In addition to machine vision, wafer robotic arms utilize force sensors. These sensors measure the pressure applied during wafer handling, ensuring gentle and safe transfers. Engineers also incorporate environmental sensors to monitor cleanroom conditions. These sensors detect any changes in temperature, humidity, or particle levels, allowing the robotic arms to adjust their operations accordingly.

Software and Control Systems

Software and control systems serve as the brains of wafer robotic arms. Engineers develop sophisticated algorithms to manage the robots’ movements and tasks. These algorithms enable the robotic arms to perform complex operations with precision and speed. They also facilitate seamless communication between the robots and other manufacturing equipment.

Control systems play a vital role in ensuring the safety and efficiency of wafer robotic arms. Engineers design these systems to monitor the robots’ performance continuously. They implement fail-safe mechanisms to prevent accidents and minimize downtime. Additionally, control systems allow for remote monitoring and diagnostics, providing valuable insights into the robots’ operations.

Integration with Industry 4.0 and IoT

Connectivity and Data Exchange

Industry 4.0 and the Internet of Things (IoT) have revolutionized the way wafer robotic arms operate. These technologies enable seamless connectivity and data exchange between machines, enhancing their functionality. Wafer robotic arms now communicate with other equipment in real-time, sharing vital information that optimizes manufacturing processes. This connectivity allows for better coordination and synchronization, reducing downtime and increasing productivity.

Data exchange plays a crucial role in improving the performance of wafer robotic arms. They collect and analyze vast amounts of data from various sensors and systems. This data provides insights into the robots’ operations, helping engineers identify areas for improvement. By leveraging this information, manufacturers can fine-tune their processes, ensuring that wafer robotic arms operate at peak efficiency.

Automation and Smart Manufacturing

Automation lies at the heart of smart manufacturing, and wafer robotic arms are key players in this transformation. These robots automate repetitive tasks, freeing up human workers to focus on more complex activities. This shift not only increases efficiency but also enhances the quality of semiconductor products. Wafer robotic arms perform tasks with precision and consistency, minimizing errors and defects.

Smart manufacturing involves the integration of advanced technologies, such as AI and machine learning, into the production process. Wafer robotic arms utilize these technologies to adapt to changing conditions and optimize their operations. They learn from past experiences, continuously improving their performance. This adaptability ensures that manufacturers can meet the ever-evolving demands of the semiconductor industry.

Market Impact and Future Trends

Current Market Landscape

The current market for wafer robotic arms is experiencing significant growth. Semiconductor manufacturers increasingly rely on these advanced machines to enhance production efficiency and precision. The demand for semiconductor devices continues to rise, driven by technological advancements in consumer electronics, automotive, and telecommunications sectors. Wafer robotic arms play a crucial role in meeting this demand by streamlining manufacturing processes and reducing production costs.

Manufacturers of wafer robotic arms are investing heavily in research and development. They aim to introduce innovative features that cater to the evolving needs of the semiconductor industry. These innovations include enhanced sensor technologies, improved mechanical designs, and advanced software systems. As a result, wafer robotic arms are becoming more versatile and capable of handling complex tasks with ease.

The competitive landscape in the wafer robotic arm market is dynamic. Several key players dominate the industry, each striving to offer superior products and services. Companies focus on building strong partnerships with semiconductor manufacturers to gain a competitive edge. This collaboration ensures that wafer robotic arms are tailored to specific manufacturing requirements, enhancing their effectiveness and reliability.

Future Directions

The future of wafer robotic arms looks promising, with several trends shaping their development. One significant trend is the integration of artificial intelligence and machine learning. These technologies enable wafer robotic arms to learn from past experiences and adapt to new challenges. This adaptability enhances their performance and ensures they remain relevant in a rapidly changing industry.

Another trend is the increasing emphasis on sustainability. Manufacturers are exploring eco-friendly materials and energy-efficient designs for wafer robotic arms. These efforts align with the broader industry goal of reducing environmental impact and promoting sustainable manufacturing practices.

The rise of Industry 4.0 and the Internet of Things (IoT) will continue to influence the evolution of wafer robotic arms. These technologies facilitate seamless connectivity and data exchange, allowing for real-time monitoring and optimization of manufacturing processes. Wafer robotic arms will become integral components of smart factories, contributing to increased automation and productivity.

Wafer Robotic Arms embody technological advancements that drive semiconductor manufacturing forward. These arms integrate mechanical design, sensor technologies, and sophisticated software, showcasing innovation at its finest. Industry 4.0 and IoT have revolutionized wafer handling robots, enhancing connectivity and data exchange. This transformation boosts efficiency and precision in manufacturing processes. The market for Wafer Robotic Arms continues to grow, with future trends pointing towards AI integration and sustainable practices. These developments promise to further elevate the capabilities and impact of these essential manufacturing tools.

FAQ

What are wafer robotic arms?

Wafer robotic arms are advanced machines used in semiconductor manufacturing. They handle wafers with precision and efficiency, ensuring high-quality production.

How do wafer robotic arms improve manufacturing processes?

They automate repetitive tasks, reducing human error and increasing throughput. This automation leads to faster production cycles and cost savings.

What role does AI play in wafer robotic arms?

AI enhances the adaptability and efficiency of wafer robotic arms. It allows them to learn from past experiences and optimize their operations in real-time.

Why is precision important in wafer handling?

Precision ensures that each wafer is processed accurately, minimizing errors and maximizing yield. It is crucial for maintaining the quality of semiconductor products.

How do sensor technologies benefit wafer robotic arms?

Sensors provide critical data for precise positioning and alignment. They ensure gentle handling and monitor cleanroom conditions, enhancing the robots’ capabilities.

What is the significance of Industry 4.0 in wafer robotic arms?

Industry 4.0 facilitates seamless connectivity and data exchange. It enables real-time monitoring and optimization, improving the efficiency of manufacturing processes.

How do wafer robotic arms contribute to cleanroom standards?

Their design minimizes contamination risks, ensuring wafers remain pristine. This capability is essential for producing high-quality semiconductor devices.

What are the future trends for wafer robotic arms?

Future trends include AI integration, sustainable practices, and enhanced connectivity. These developments promise to elevate the capabilities of wafer robotic arms.

How does the market for wafer robotic arms look currently?

The market is experiencing significant growth due to rising demand for semiconductors. Manufacturers invest in research and development to introduce innovative features.

What challenges do wafer robotic arms face?

Challenges include maintaining precision in complex tasks and adapting to evolving industry demands. Continuous innovation and development address these challenges.