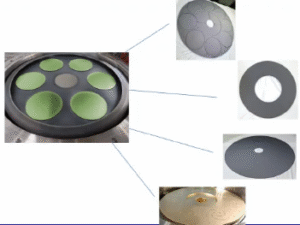

Plasma Enhanced Chemical Vapor Deposition (PECVD) pallet applications play a crucial role in modern industries. They enable the deposition of thin films with exceptional precision and uniformity. Industries rely on PECVD technology for its ability to process materials at low temperatures, making it ideal for sensitive substrates. This capability ensures that delicate components remain intact during the coating process. PECVD pallets enhance the performance and durability of products across various sectors, including electronics, photovoltaics, and biomedical fields. Their significance continues to grow as industries demand more advanced and reliable solutions.

Key Takeaways

- PECVD technology enables precise and uniform thin film deposition, crucial for enhancing product performance across various industries.

- Low-temperature processing in PECVD protects sensitive substrates, ensuring the integrity of delicate components during coating.

- In the electronics sector, PECVD pallets are essential for semiconductor manufacturing, providing high-quality dielectric layers that improve device reliability.

- PECVD significantly boosts solar cell efficiency by applying anti-reflective and passivation coatings, leading to better light absorption and performance.

- Biomedical applications benefit from PECVD through biocompatible coatings that enhance the safety and functionality of medical devices.

- The food packaging industry utilizes PECVD for metallized coatings that improve barrier properties, extending shelf life and maintaining product quality.

- Future advancements in PECVD technology may include improved plasma control and new materials, further enhancing its industrial applications.

The PECVD Process

Preparation

Substrate cleaning and setup

In the PECVD process, preparation begins with meticulous substrate cleaning. Technicians remove contaminants to ensure optimal adhesion of the film. They employ various cleaning techniques, such as chemical baths and ultrasonic cleaning, to achieve a pristine surface. After cleaning, they set up the substrate in the deposition chamber. Proper alignment and secure placement are crucial to prevent movement during the process.

Initial conditions for deposition

Establishing initial conditions is vital for successful PECVD operations. Technicians adjust parameters like temperature, pressure, and gas flow rates. These settings create an environment conducive to uniform film deposition. They carefully monitor these conditions to maintain consistency throughout the process.

Plasma Formation

Role of gases and energy sources

Gases and energy sources play a pivotal role in plasma formation. Technicians introduce precursor gases into the chamber, which react to form the desired film. They use energy sources, such as radio frequency or microwave power, to ionize the gases. This ionization generates plasma, a key component in the PECVD process.

Plasma characteristics and control

Controlling plasma characteristics ensures high-quality film deposition. Technicians adjust parameters like power density and gas composition to influence plasma behavior. They monitor plasma properties, such as electron density and temperature, to maintain stability. Precise control over these factors leads to consistent and reliable PECVD pallet applications.

Film Deposition

Layer formation and thickness control

Film deposition involves the formation of thin layers on the substrate. Technicians control layer thickness by adjusting deposition time and gas flow rates. They aim for precise thickness control to meet specific application requirements. This precision is essential for achieving the desired electrical and optical properties of the film.

Quality and uniformity of films

Ensuring film quality and uniformity is a primary goal in PECVD processes. Technicians strive for smooth, defect-free surfaces with consistent thickness across the substrate. They use advanced monitoring techniques, such as in-situ ellipsometry, to assess film quality. High-quality films enhance the performance and longevity of products in various industries.

Applications of PECVD Pallets

Electronics Industry

Semiconductor manufacturing

In semiconductor manufacturing, PECVD pallets play a pivotal role. They enable the deposition of thin films essential for creating integrated circuits. Manufacturers rely on PECVD technology to produce high-quality dielectric layers. These layers provide insulation and protection for semiconductor devices. The precision and uniformity of PECVD films enhance device performance and reliability. By using PECVD pallets, manufacturers achieve consistent results, crucial for the demanding standards of the electronics industry.

Microelectromechanical systems (MEMS)

Microelectromechanical systems (MEMS) benefit significantly from PECVD pallet applications. MEMS devices require precise and uniform coatings to function effectively. PECVD technology provides the necessary thin films for these miniature systems. It ensures that MEMS components maintain their structural integrity and performance. The ability to deposit films at low temperatures makes PECVD ideal for MEMS, as it prevents damage to sensitive materials. This capability supports the development of advanced MEMS technologies used in various applications, from sensors to actuators.

Photovoltaics

Solar cell efficiency improvements

PECVD pallets contribute to significant improvements in solar cell efficiency. They enable the deposition of anti-reflective coatings, which enhance light absorption. This increased absorption boosts the overall efficiency of solar cells. PECVD technology also allows for the creation of passivation layers. These layers reduce surface recombination, further improving cell performance. By utilizing PECVD pallets, manufacturers produce more efficient and cost-effective solar cells, advancing the photovoltaic industry.

Cost-effective production techniques

The photovoltaic industry benefits from the cost-effective production techniques enabled by PECVD pallets. PECVD technology reduces material waste and energy consumption during film deposition. This efficiency lowers production costs, making solar energy more accessible. Manufacturers can produce high-quality solar cells at a competitive price point. The scalability of PECVD processes supports large-scale production, meeting the growing demand for renewable energy solutions.

Biomedical Applications

Biocompatible coatings

In biomedical applications, PECVD pallets provide biocompatible coatings essential for medical devices. These coatings ensure that devices interact safely with biological tissues. PECVD technology allows for the deposition of thin films with excellent adhesion and uniformity. This precision is crucial for maintaining the functionality and safety of medical implants and instruments. By using PECVD pallets, manufacturers create coatings that enhance the biocompatibility of medical devices, improving patient outcomes.

Medical device enhancements

PECVD pallets contribute to significant enhancements in medical devices. They enable the deposition of protective and functional coatings. These coatings improve the durability and performance of medical instruments. PECVD technology allows for the customization of film properties to meet specific medical requirements. This flexibility supports the development of innovative medical technologies. By leveraging PECVD pallets, manufacturers produce advanced devices that meet the stringent standards of the healthcare industry.

Food Packaging

Metallized coatings for barrier properties

In the food packaging industry, PECVD pallet applications significantly enhance product preservation. They apply metallized coatings to packaging materials, which improve barrier properties. These coatings prevent moisture, oxygen, and other gases from penetrating the packaging. This protection extends the shelf life of food products, maintaining their freshness and quality.

Manufacturers utilize PECVD technology to achieve uniform and consistent coatings. The precision of PECVD ensures that the metallized layers adhere well to the substrate. This adhesion is crucial for maintaining the integrity of the barrier properties. By using PECVD pallets, manufacturers produce packaging that meets stringent industry standards.

The application of metallized coatings also contributes to the aesthetic appeal of packaging. These coatings provide a shiny, metallic finish that enhances the visual appeal of products. This visual enhancement can influence consumer purchasing decisions, making PECVD technology a valuable tool in the competitive food packaging market.

Materials Used in PECVD Pallets

Common Materials

Silicon-based compounds

Silicon-based compounds form the backbone of many PECVD pallet applications. These compounds, such as silicon nitride and silicon dioxide, offer excellent dielectric properties. They provide insulation and protection for electronic components. Silicon-based materials also exhibit high thermal stability, making them suitable for various industrial applications. Their ability to form thin, uniform films enhances the performance of devices in the electronics and semiconductor industries.

Metal oxides and nitrides

Metal oxides and nitrides serve as essential materials in PECVD processes. Compounds like titanium nitride and aluminum oxide offer unique properties. They provide excellent hardness and wear resistance, which are crucial for protective coatings. Metal oxides and nitrides also contribute to the electrical conductivity of films. This conductivity is vital for applications in microelectronics and photovoltaics. The versatility of these materials supports their use in diverse industrial sectors.

Material Properties

Thermal stability

Thermal stability remains a critical property for materials used in PECVD pallets. High thermal stability ensures that films maintain their integrity under varying temperature conditions. This stability is essential for applications in electronics and photovoltaics, where devices often experience thermal stress. Materials with superior thermal stability enhance the reliability and longevity of products.

Electrical conductivity

Electrical conductivity plays a significant role in the functionality of PECVD films. Conductive materials enable the flow of electrical current, which is vital for electronic applications. Films with high electrical conductivity improve the efficiency of devices such as solar cells and integrated circuits. The ability to control conductivity through material selection and deposition parameters allows for tailored solutions in various industries.

PECVD pallet applications have revolutionized various industries by enabling precise and uniform thin film deposition. These applications enhance product performance and durability across sectors like electronics, photovoltaics, and biomedical fields. The materials used in PECVD processes, such as silicon-based compounds and metal oxides, offer excellent thermal stability and electrical conductivity. Looking ahead, advancements in PECVD technology may lead to more efficient and cost-effective solutions. Innovations could include improved plasma control techniques and the development of new materials, further expanding the potential of PECVD pallets in industrial applications.

FAQ

What is PECVD, and how does it work?

Plasma Enhanced Chemical Vapor Deposition (PECVD) is a process that uses plasma energy to deposit thin films on substrates. Technicians introduce precursor gases into a chamber and apply energy sources like radio frequency or microwave power. This energy ionizes the gases, forming plasma, which facilitates the chemical reactions needed for film deposition.

Why is PECVD preferred for low-temperature processing?

PECVD operates at lower temperatures compared to other deposition methods. This feature makes it ideal for sensitive substrates that cannot withstand high temperatures. It ensures that delicate components remain intact during the coating process, preserving their structural integrity.

What industries benefit most from PECVD pallet applications?

PECVD pallet applications benefit several industries, including electronics, photovoltaics, biomedical fields, and food packaging. Each sector utilizes PECVD technology to enhance product performance, durability, and efficiency through precise and uniform thin film deposition.

How does PECVD improve solar cell efficiency?

PECVD improves solar cell efficiency by depositing anti-reflective and passivation coatings. These coatings enhance light absorption and reduce surface recombination, respectively. As a result, solar cells achieve higher efficiency and better performance.

What materials are commonly used in PECVD processes?

Common materials used in PECVD processes include silicon-based compounds like silicon nitride and silicon dioxide, as well as metal oxides and nitrides such as titanium nitride and aluminum oxide. These materials offer excellent dielectric properties, thermal stability, and electrical conductivity.

How does PECVD contribute to medical device enhancements?

PECVD contributes to medical device enhancements by providing biocompatible and protective coatings. These coatings ensure safe interaction with biological tissues and improve the durability and performance of medical instruments. PECVD technology allows for customization to meet specific medical requirements.

What role do gases play in the PECVD process?

Gases play a crucial role in the PECVD process. Technicians introduce precursor gases into the deposition chamber, where they react to form the desired film. The choice of gases and their flow rates significantly influence the quality and characteristics of the deposited film.

How does PECVD technology support cost-effective production?

PECVD technology supports cost-effective production by reducing material waste and energy consumption. Its efficiency lowers production costs, making advanced technologies more accessible. The scalability of PECVD processes also supports large-scale production, meeting industry demands.

What are the key properties of PECVD films?

Key properties of PECVD films include excellent adhesion, uniformity, thermal stability, and electrical conductivity. These properties are essential for various applications, ensuring that films perform reliably under different conditions and enhance the functionality of devices.

What future trends can be expected in PECVD technology?

Future trends in PECVD technology may include advancements in plasma control techniques and the development of new materials. These innovations could lead to more efficient and cost-effective solutions, expanding the potential of PECVD pallets in industrial applications.