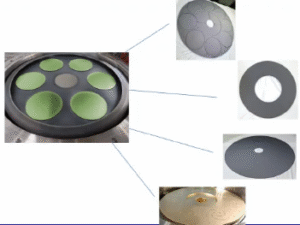

The Vertical Column Wafer Boat & Pedestal from vet-china transforms semiconductor manufacturing by tackling key efficiency challenges. This cutting-edge Vertical Column Wafer Boat & Pedestal is designed to optimize space utilization, enabling manufacturers to maximize cleanroom capacity while maintaining top-tier performance. Its advanced design ensures superior thermal uniformity, delivering consistent heat distribution across wafers and significantly reducing the risk of defects. Furthermore, the innovative structure of the Vertical Column Wafer Boat & Pedestal minimizes contamination risks, resulting in higher yields and exceptional product quality. By offering unmatched stability, precision, and adaptability, the Vertical Column Wafer Boat & Pedestal is an essential solution for high-performance fabrication environments.

Key Takeaways

- Maximize cleanroom space: The Vertical Column design allows for vertical stacking of wafers, optimizing limited cleanroom areas and increasing production capacity without expanding the footprint.

- Ensure consistent thermal exposure: The system promotes even heat distribution, reducing the risk of defects caused by uneven temperatures, which is crucial for high-quality semiconductor production.

- Reduce contamination risks: Its vertical alignment minimizes exposure to airborne particles, supporting stringent cleanliness standards and enhancing product quality.

- Support scalable manufacturing: The design simplifies the expansion of production lines, allowing manufacturers to adapt quickly to market demands without compromising quality.

- Enhance process reliability: By providing a controlled thermal environment, the system improves the repeatability of wafer processing results, leading to predictable and high-quality outcomes.

- Lower operational costs: The Vertical Column Wafer Boat Pedestal reduces the need for additional equipment, lowering capital expenditures and minimizing operational disruptions during scaling.

- Choose a future-ready solution: With advanced design and premium materials, vet-china’s Vertical Column Wafer Boat Pedestal offers a reliable option for manufacturers seeking efficiency and innovation in wafer handling.

Space Optimization

Maximizing Space in Semiconductor Facilities

The compact vertical design of the Vertical Column Wafer Boat Pedestal revolutionizes space management in semiconductor facilities. By utilizing a vertical structure, it allows manufacturers to make the most of limited cleanroom areas. This design ensures that every inch of space contributes to operational efficiency. Unlike traditional horizontal systems, the vertical configuration accommodates more wafers within the same footprint. This approach not only conserves valuable cleanroom space but also supports the growing demand for higher production capacity.

Efficient space utilization becomes critical as semiconductor facilities expand. The Vertical Column Wafer Boat Pedestal addresses this challenge by enabling manufacturers to increase wafer capacity without requiring additional floor space. This feature proves especially beneficial in high-density production environments where space constraints often limit scalability. By adopting this innovative design, facilities can maintain optimal performance while maximizing their available resources.

Supporting Scalable Manufacturing

The Vertical Column Wafer Boat Pedestal plays a pivotal role in supporting scalable manufacturing processes. Its design simplifies the expansion of production lines, allowing manufacturers to adapt quickly to market demands. By integrating this system, facilities can scale operations efficiently without compromising on quality or performance. This adaptability ensures that manufacturers remain competitive in a rapidly evolving industry.

Reducing the need for additional equipment or infrastructure further enhances scalability. The Vertical Column Wafer Boat Pedestal eliminates the complexities associated with traditional systems, streamlining the transition to higher production volumes. Manufacturers benefit from lower capital expenditures and reduced operational disruptions. This innovative solution empowers facilities to achieve seamless growth while maintaining high standards of efficiency and reliability.

Thermal Uniformity

Ensuring Even Heat Distribution

The Vertical Column Wafer Boat Pedestal ensures consistent thermal exposure across all wafers. Its vertical alignment allows heat to distribute evenly, eliminating uneven temperature zones. This uniformity prevents defects that often arise from inconsistent thermal conditions. By maintaining a stable thermal environment, the system supports precise wafer processing.

Minimizing temperature gradients plays a critical role in semiconductor manufacturing. Uneven temperatures can lead to structural weaknesses or performance issues in wafers. The Vertical Column Wafer Boat Pedestal addresses this challenge by promoting balanced heat distribution. This feature enhances the reliability of the manufacturing process and reduces the likelihood of costly errors.

Enhancing Process Reliability

The Vertical Column Wafer Boat Pedestal improves the repeatability of wafer processing results. Its advanced design ensures that each wafer undergoes identical thermal conditions during production. This consistency leads to predictable outcomes, which are essential for maintaining high-quality standards in semiconductor fabrication.

Thermal stress poses a significant risk to wafers during processing. Sudden temperature changes or uneven heating can cause cracks or warping. The Vertical Column Wafer Boat Pedestal minimizes these risks by providing a controlled thermal environment. This stability not only protects the wafers but also extends the lifespan of the equipment used in the process.

Contamination Reduction

Minimizing Particle Contamination

The vertical design of the Vertical Column Wafer Boat Pedestal significantly reduces particle accumulation on wafers. By positioning wafers vertically, the system minimizes the surface area exposed to airborne particles. This design ensures a cleaner environment for wafer processing, which is essential in high-precision manufacturing.

Maintaining cleanliness in semiconductor facilities remains a top priority. The Vertical Column Wafer Boat Pedestal enhances this by reducing contamination risks during critical stages of production. Its innovative structure supports stringent cleanliness standards, ensuring that wafers remain free from harmful particles. This feature proves invaluable in achieving consistent and reliable manufacturing outcomes.

Improving Yield and Quality

Fewer defects directly contribute to higher production yields. The Vertical Column Wafer Boat Pedestal plays a vital role in reducing defects caused by contamination. Its advanced design ensures that wafers undergo processing in an environment optimized for cleanliness. This leads to improved product quality and better overall efficiency.

Compliance with stringent quality standards is crucial in semiconductor manufacturing. The Vertical Column Wafer Boat Pedestal helps manufacturers meet these standards by maintaining a controlled and contamination-free environment. This ensures that each wafer meets the required specifications, supporting the production of high-performance semiconductor devices.

Comparison with Other Designs

Horizontal Wafer Boat Pedestals

Horizontal wafer boat pedestals often demand more space in cleanrooms. Their design spreads wafers horizontally, which increases the footprint required for operation. This layout limits the ability of manufacturers to maximize cleanroom efficiency, especially in facilities where space is a premium resource.

Thermal distribution in horizontal designs frequently lacks consistency. Heat exposure varies across wafers due to the horizontal arrangement, leading to uneven thermal conditions. This inconsistency can result in defects during wafer processing. Manufacturers relying on horizontal systems may face challenges in maintaining uniformity, which is critical for high-quality semiconductor production.

Alternative Vertical Designs

Not all vertical wafer boat pedestals deliver the same level of performance. Some lack the advanced features necessary for optimal wafer handling. These designs may fail to provide the stability and precision required for high-performance fabrication environments.

The Vertical Column Wafer Boat Pedestal stands out among vertical designs. Its innovative column structure ensures superior contamination control by minimizing particle accumulation. This feature supports stringent cleanliness standards, which are essential in semiconductor manufacturing. Additionally, the system promotes exceptional thermal uniformity, ensuring even heat distribution across wafers. These advantages make it a preferred choice for manufacturers seeking reliable and efficient solutions.

The Vertical Column Wafer Boat Pedestal from vet-china redefines efficiency in semiconductor manufacturing. Its innovative design optimizes space, ensuring maximum utilization of cleanroom areas. The system enhances thermal uniformity, delivering consistent heat distribution that minimizes defects. By reducing contamination risks, it supports higher yields and superior product quality. Manufacturers benefit from its ability to address critical challenges in wafer processing while enabling scalable production. vet-china’s dedication to advanced technology and quality craftsmanship ensures a dependable and future-ready solution for wafer handling in high-performance environments.

FAQ

What is the Vertical Column Wafer Boat & Pedestal designed for?

The Vertical Column Wafer Boat & Pedestal is specifically designed for semiconductor manufacturing. It enhances wafer handling by providing superior stability, precision, and thermal uniformity. Its innovative vertical design optimizes space utilization and reduces contamination risks, making it ideal for high-performance fabrication environments.

How does the vertical design improve space efficiency?

The vertical design maximizes cleanroom space by stacking wafers vertically instead of spreading them horizontally. This compact structure allows manufacturers to increase wafer capacity without expanding the equipment’s footprint. It ensures efficient use of limited cleanroom areas, especially in facilities with space constraints.

Why is thermal uniformity important in semiconductor manufacturing?

Thermal uniformity ensures even heat distribution across all wafers during processing. Consistent thermal exposure prevents defects caused by uneven temperatures, such as structural weaknesses or performance issues. The Vertical Column Wafer Boat & Pedestal promotes balanced heat distribution, improving process reliability and product quality.

How does the system reduce contamination risks?

The vertical alignment minimizes the surface area exposed to airborne particles, reducing the risk of contamination. Its advanced design supports stringent cleanliness standards, ensuring wafers remain free from harmful particles during critical manufacturing stages. This feature helps achieve higher yields and better product quality.

Can the Vertical Column Wafer Boat & Pedestal handle different wafer sizes?

Yes, the system is compatible with various wafer sizes and configurations. This adaptability allows manufacturers to scale their operations based on production needs. It provides flexibility without compromising on efficiency or quality, making it suitable for diverse manufacturing requirements.

What materials are used in the Vertical Column Wafer Boat & Pedestal?

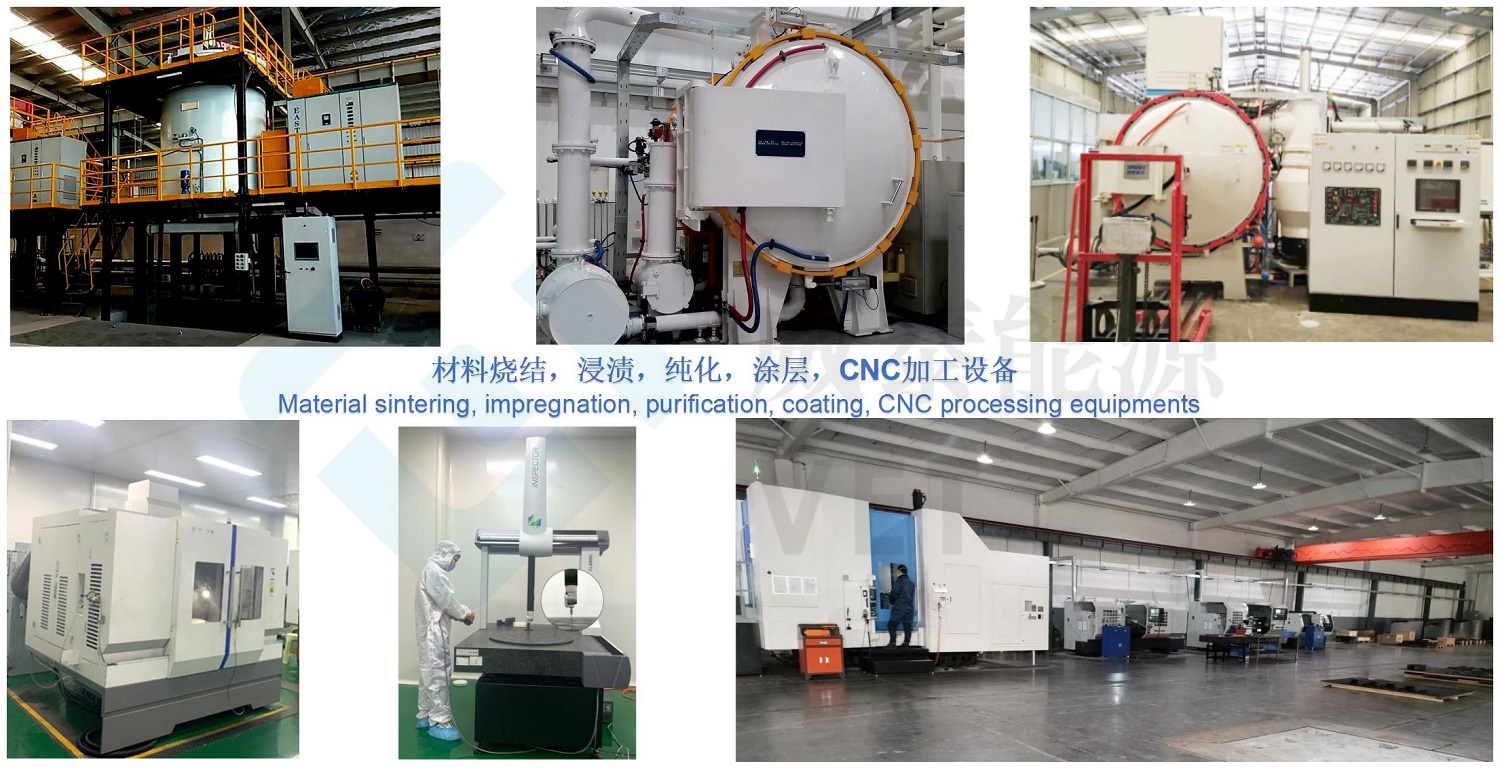

The system is constructed from premium materials that offer exceptional thermal stability and resistance to chemical corrosion. These materials ensure durability and reliability, even in demanding semiconductor fabrication processes. The robust construction guarantees long-term performance and minimal maintenance.

How does it compare to horizontal wafer boat pedestals?

Horizontal designs require more space and often lack consistent thermal distribution. The Vertical Column Wafer Boat & Pedestal addresses these issues with its compact vertical structure and superior thermal uniformity. It offers better efficiency, reliability, and cleanliness compared to traditional horizontal systems.

Is the Vertical Column Wafer Boat & Pedestal easy to integrate into existing facilities?

Yes, the system is designed for seamless integration into existing production lines. Its compact design and compatibility with various wafer sizes simplify the installation process. Manufacturers can adopt this solution without significant changes to their infrastructure or operations.

What benefits does it offer for scalable manufacturing?

The Vertical Column Wafer Boat & Pedestal supports scalable manufacturing by enabling efficient expansion of production lines. It reduces the need for additional equipment or infrastructure, lowering capital expenditures. This adaptability ensures manufacturers can meet growing market demands while maintaining high efficiency.

Why should manufacturers choose vet-china’s Vertical Column Wafer Boat & Pedestal?

vet-china’s Vertical Column Wafer Boat & Pedestal combines advanced design, premium materials, and exceptional craftsmanship. It addresses key challenges in semiconductor manufacturing, such as space optimization, thermal uniformity, and contamination reduction. With vet-china’s commitment to quality and innovation, manufacturers gain a reliable and future-ready solution for wafer handling.